Nissan Frontier D40. Manual - part 601

EM-136

< ON-VEHICLE MAINTENANCE >

[VQ40DE]

COMPRESSION PRESSURE

COMPRESSION PRESSURE

Compression Pressure

INFOID:0000000005274324

CHECKING COMPRESSION PRESSURE

1.

Warm up engine thoroughly.

2.

Release fuel pressure. Refer to

.

3.

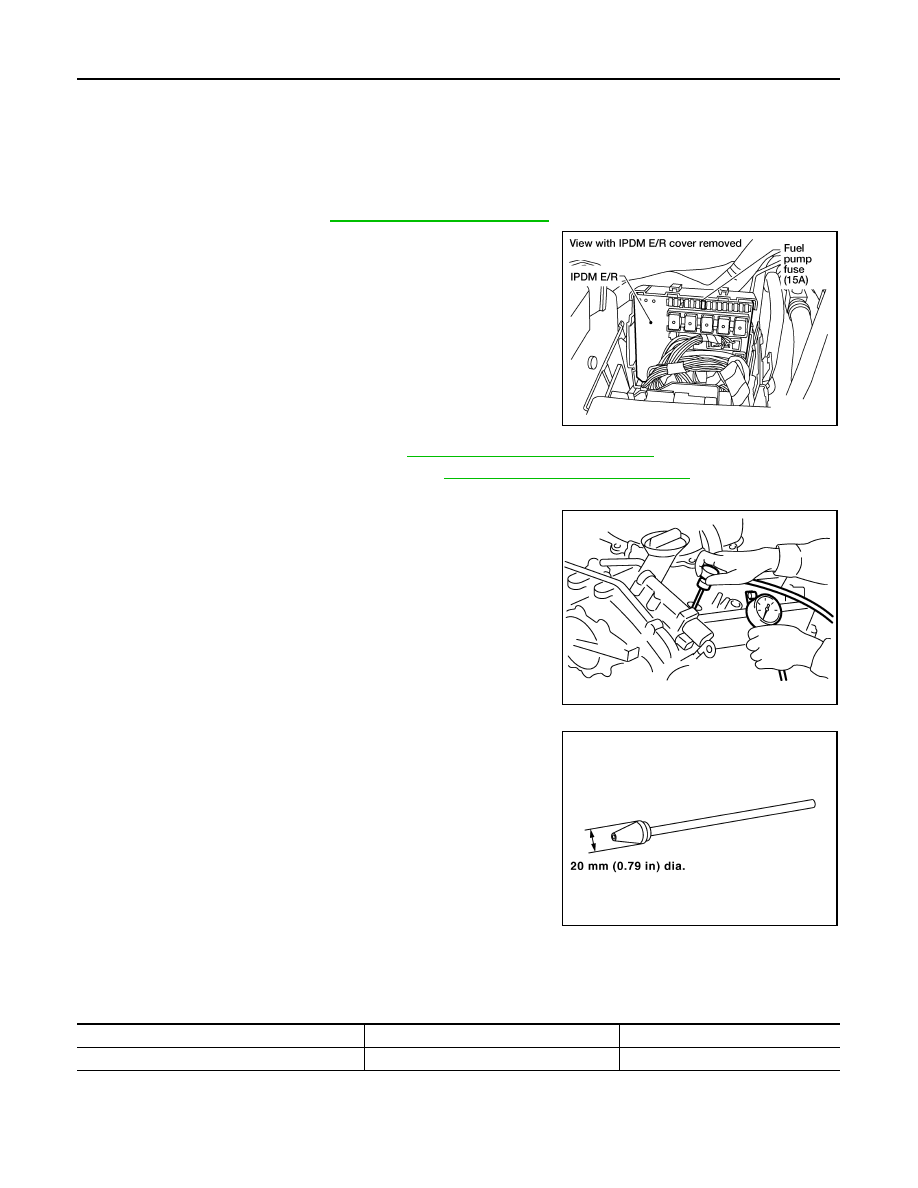

Disconnect fuel pump fuse to avoid fuel injection during mea-

surement.

4.

Remove intake manifold collector. Refer to

EM-140, "Removal and Installation"

5.

Remove spark plug from each cylinder. Refer to

EM-130, "Removal and Installation"

.

6.

Connect engine tachometer (not required in use of CONSULT-III).

7.

Install compression tester with adapter onto spark plug hole.

• Use compression gauge whose pick up end inserted to spark

plug hole is smaller than 20 mm (0.79 in) in diameter. Other-

wise, it may be caught by cylinder head during removal.

8.

Turn ignition switch to “START” for cranking. When the gauge pointer stabilizes, read the compression

pressure and engine rpm. Perform these steps to check each cylinder.

Compression pressure:

Unit: kPa (kg/cm

2

, psi) /rpm

CAUTION:

Always use a fully charged battery to obtain specified engine speed.

• If the engine speed is out of the specified range, check the battery liquid for proper gravity. Check the

engine speed again with normal battery gravity.

BBIA0534E

PBIC0900E

SBIA0533E

Standard

Minimum

Differential limit between cylinders

1,275 (13.0, 185) / 300

981 (10.0, 142) / 300

98 (1.0, 14) / 300