Nissan Frontier D40. Manual - part 588

EM-84

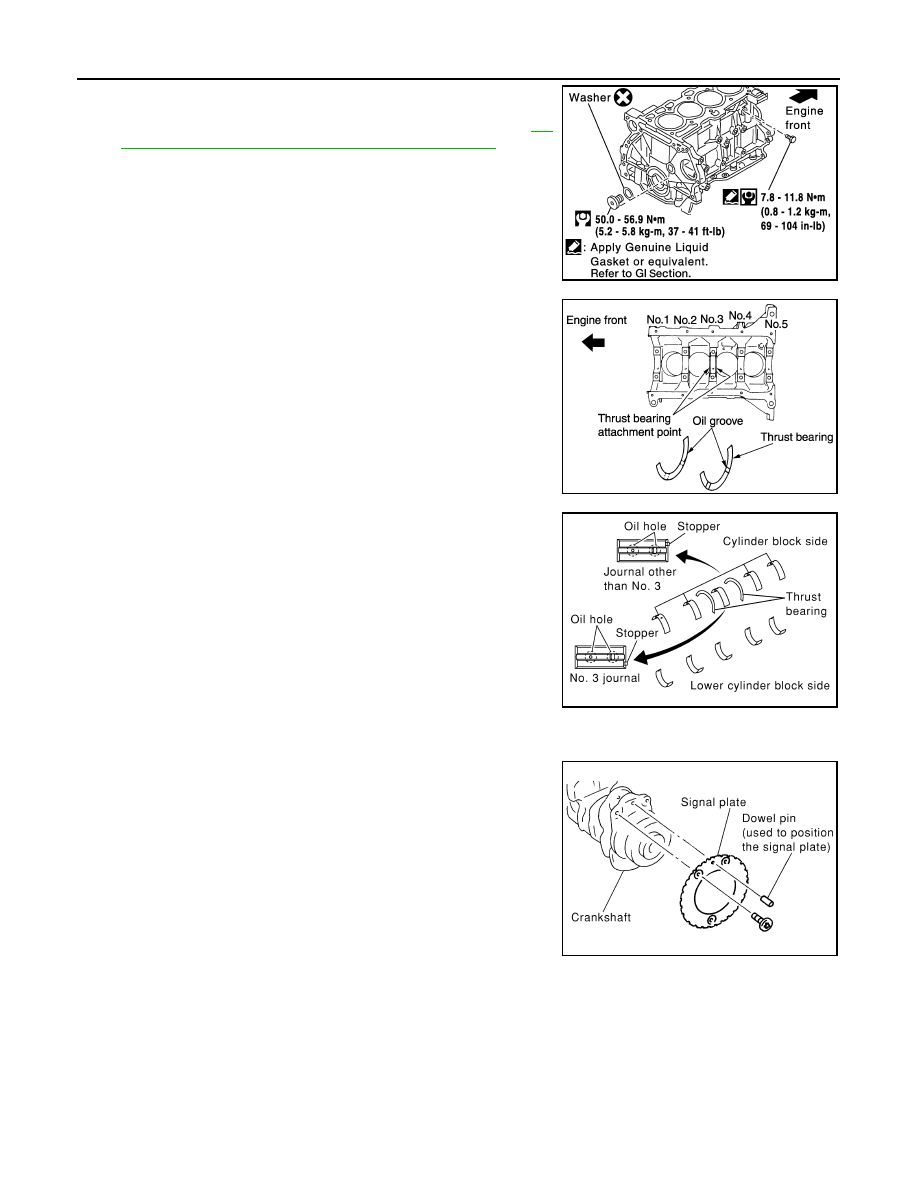

< DISASSEMBLY AND ASSEMBLY >

[QR25DE]

ENGINE UNIT

2.

Apply Silicone RTV Sealant to the drain plugs. Install the drain

plugs on the cylinder block.

• Use Genuine Silicone RTV Sealant, or equivalent. Refer to

22, "Recommended Chemical Products and Sealants"

.

• Replace the copper washers with new ones.

3.

Install main bearings and thrust bearings as follows:

a.

Remove dust, dirt, and engine oil from the bearing mating sur-

faces of the cylinder block and lower cylinder block.

b.

Install the thrust bearings to both sides of the No. 3 main bearing

journal on the cylinder block.

• Install the thrust bearings with the oil groove facing the crank-

shaft arm (outside).

c.

Install the main bearings paying attention to their position and

direction.

• The main bearing with an oil hole and groove goes on the cyl-

inder block. The one without them goes on the lower cylinder

block.

• Only the main bearing (on the cylinder block) for No. 3 journal

has different specifications.

• Before installing the bearings, apply engine oil to the bearing

friction surface (inside). Do not apply oil to the back surface,

but thoroughly clean it.

• When installing, align the bearing stopper to the notch.

• Make sure that the oil holes on the cylinder block and those on

the corresponding bearing are aligned.

4.

Install the signal plate to the crankshaft.

a.

Position the crankshaft and signal plate using a positioning

dowel pin, and tighten the signal plate bolts to specification.

b.

Remove the dowel pin.

CAUTION:

Be sure to remove dowel pin before installing the crank-

shaft.

NOTE:

Dowel pins for the crankshaft and signal plate are supplied as a set for each.

5.

Install crankshaft to the cylinder block.

• While turning the crankshaft by hand, check that it turns smoothly.

CAUTION:

Do not install rear oil seal at this time.

WBIA0159E

PBIC0264E

SBIA0277E

Signal plate bolts

Type 1

: 18.5 N·m (1.9 kg-m, 14 ft-lb)

Type 2

: 22.0 N·m (2.2 kg-m, 16 ft-lb)

SBIA0278E