Nissan Frontier D40. Manual - part 585

EM-72

< ON-VEHICLE REPAIR >

[QR25DE]

CYLINDER HEAD

• After confirming that the dimensions of valve guides and valves are

within specifications, perform this procedure.

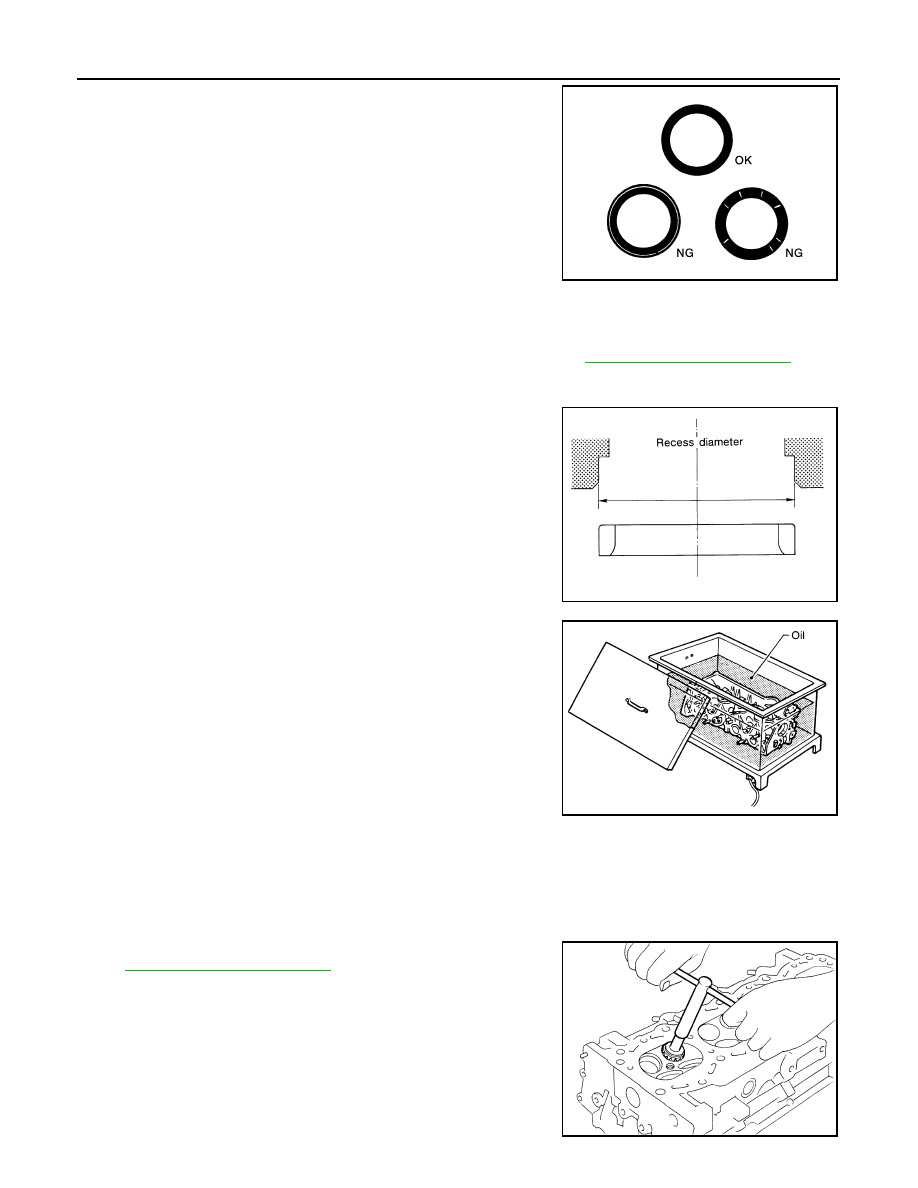

• Apply prussian blue (or white lead) onto contacting surface of valve

seat to check the condition of the valve contact on the surface.

• Check if the contact area band is continuous all around the circum-

ference.

• If not, grind to adjust valve fitting and check again. If the contacting

surface still has NG conditions even after the re-check, replace

valve seat.

VALVE SEAT REPLACEMENT

When valve seat is removed, replace with oversized [0.5 mm (0.020 in)] valve seat.

1.

Bore out old seat until it collapses. Boring should not continue beyond the bottom face of the seat recess

in cylinder head. Set the machine depth stop to ensure this. Refer to

.

CAUTION:

Prevent scratching cylinder head by excessive boring.

2.

Ream cylinder head recess diameter for service valve seat.

• Be sure to ream in circles concentric to the valve guide center.

This will enable valve seat to fit correctly.

3.

Heat cylinder head to 110

°

to 130

°

C (230

°

to 266

°

F) by soaking

in heated oil.

4.

Provide valve seats cooled well with dry ice. Force fit valve seats into cylinder head.

WARNING:

• Cylinder head contains heat. When working, wear protective equipment to avoid getting burned.

CAUTION:

• Avoid directly touching cold valve seats.

5.

Finish seat to the specified dimensions using suitable tool. Refer

to

.

CAUTION:

When using valve seat cutter, firmly grip cutter handle with

both hands. Then, press on the contacting surface all

around the circumference to cut in a single drive. Improper

pressure on the cutter or cutting many different times may

result in staged valve seat.

SBIA0322E

Oversize [0.5 mm (0.020 in)]

Intake

: 37.000 - 37.016 mm (1.4567 - 1.4573 in)

Exhaust

: 32.000 - 32.016 mm (1.2598 - 1.2605 in)

SEM795A

SEM008A

SEM934C