Nissan Frontier D40. Manual - part 582

EM-60

< ON-VEHICLE REPAIR >

[QR25DE]

CAMSHAFT

16. Installation is in the reverse order of removal after this step.

NOTE:

If hydraulic pressure inside timing chain tensioner drops after removal and installation, slack in the guide

may generate a pounding noise during and just after the engine start. However, this is normal. Noise will

stop after hydraulic pressure rises.

INSPECTION AFTER INSTALLATION

Inspection of Camshaft Sprocket (INT) Oil Groove

CAUTION:

• Perform this inspection only when DTC P0011 is detected in self-diagnostic results of CONSULT-III

and it is directed according to inspection procedure of EC section. Refer to

• Check when the engine is cold so as to prevent burns from any splashing engine oil.

1.

Check the engine oil level. Refer to

.

2.

Perform the following procedure so as to prevent the engine from being unintentionally started while

checking.

a.

Release fuel pressure. Refer to

.

b.

Disconnect ignition coil and injector harness connectors.

c.

Remove drive belt. Refer to

EM-14, "Removal and Installation"

.

3.

Remove intake valve timing control solenoid valve. Refer to

4.

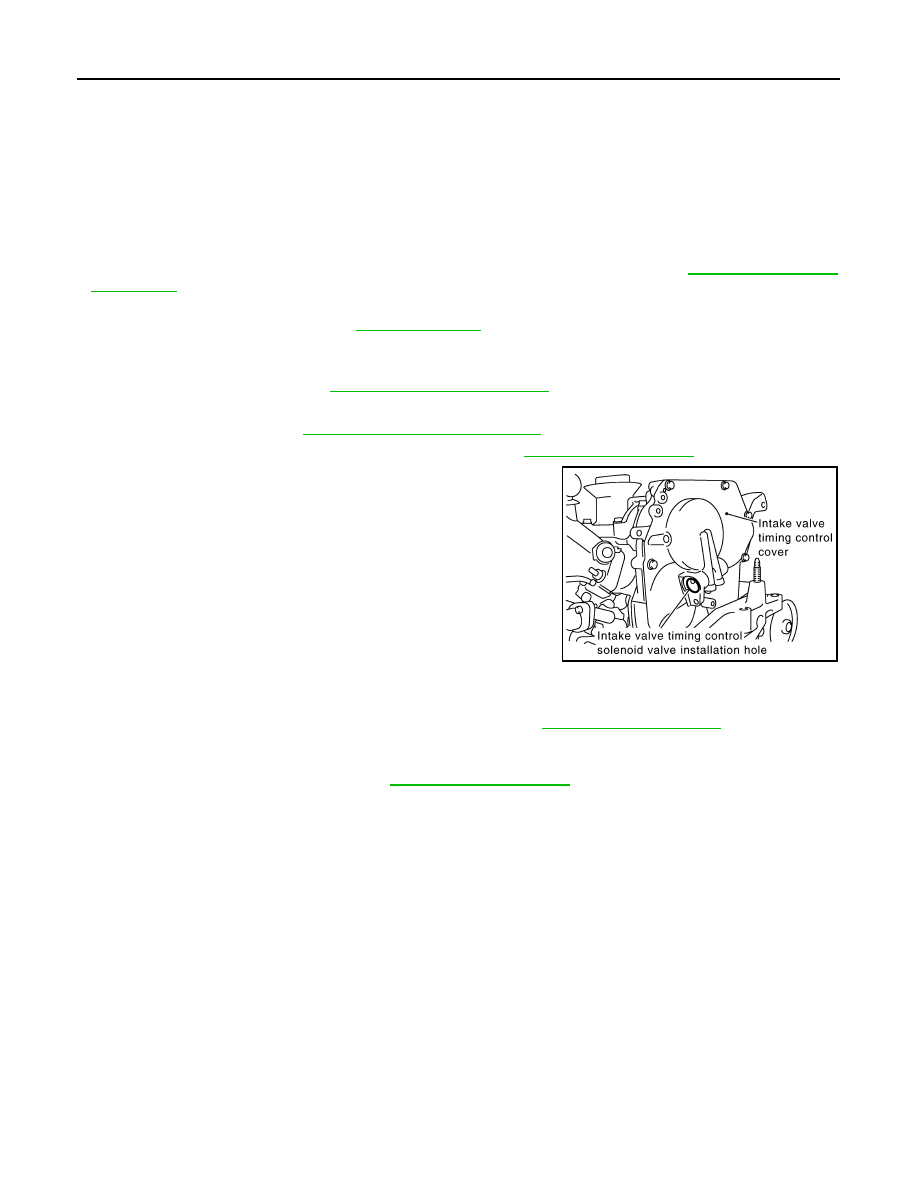

Crank the engine, and then make sure that engine oil comes out

from intake valve timing control cover oil hole. Stop cranking

after checking.

WARNING:

Be careful not to touch rotating parts (drive belt, idler pul-

ley, and crankshaft pulley, etc.).

CAUTION:

Engine oil may squirt from intake valve timing control sole-

noid valve installation hole during cranking. Use a shop

cloth to protect the engine components and the vehicle. Do

not allow engine oil to get on rubber components such as

drive belt or engine mount insulators. Immediately wipe off

any splashed engine oil.

• Clean oil groove between oil strainer and intake valve timing control solenoid valve if engine oil does not

come out from intake valve timing control cover oil hole. Refer to

.

5.

Remove components between intake valve timing control solenoid valve and camshaft sprocket (INT),

and then check each oil groove for clogging.

• Clean oil groove if necessary. Refer to

6.

Installation is in the reverse order of removal.

PBIC2723E