Nissan Frontier D40. Manual - part 580

EM-52

< ON-VEHICLE REPAIR >

[QR25DE]

CAMSHAFT

CAMSHAFT

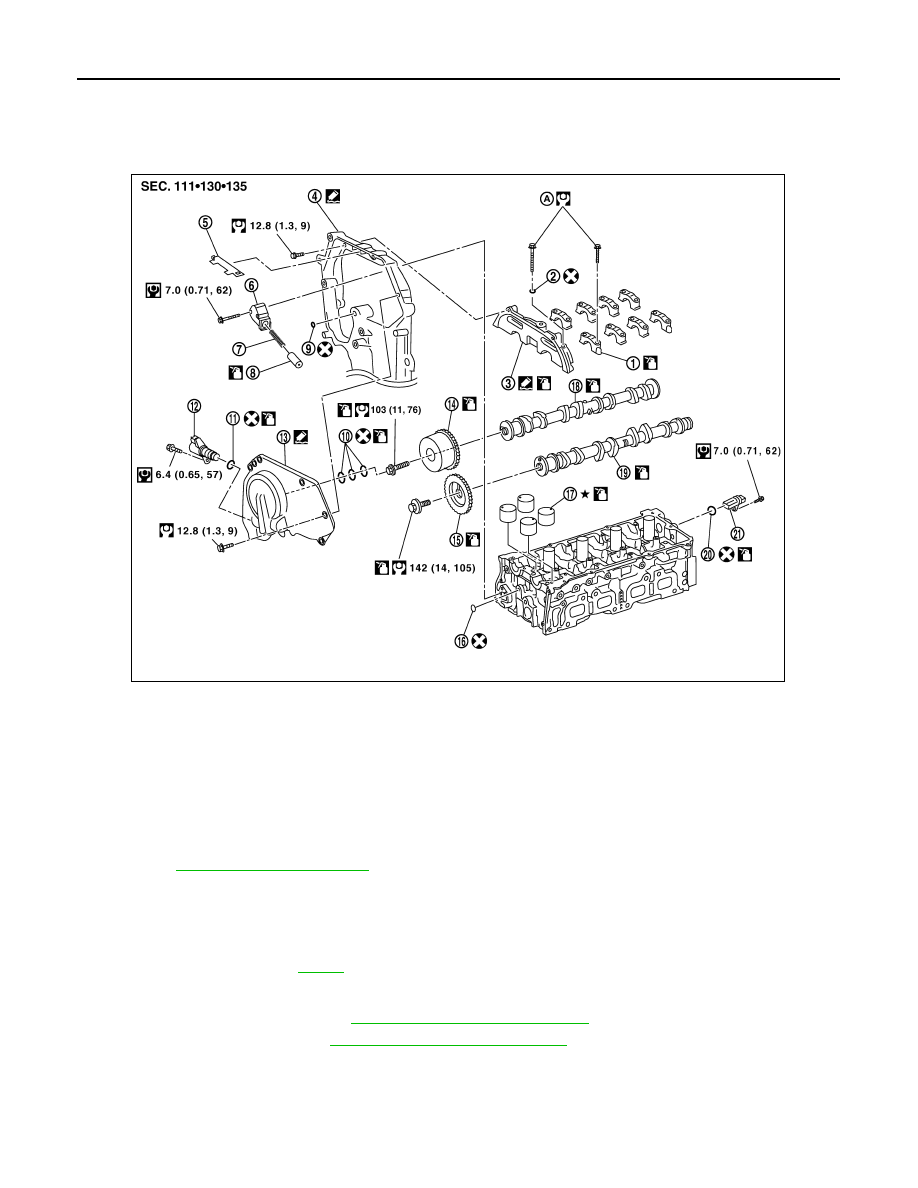

Exploded View

INFOID:0000000005274285

Removal and Installation

INFOID:0000000005274286

NOTE:

This section describes removal/installation procedure of camshaft without removing front cover. If front cover

is removed or installed, refer to

.

REMOVAL

1.

Remove the rocker cover. Refer to

EM-36, "Removal and Installation"

.

2.

Remove the drive belt. Refer to

EM-14, "Removal and Installation"

.

3.

Disconnect and remove the camshaft position sensor (PHASE).

4.

Disconnect the IVT control solenoid electrical connector.

5.

Disconnect the ground electrical connections from the front cover.

1.

Camshaft bracket (No. 2 to 5)

2.

Seal washer

3.

Camshaft bracket (No. 1)

4.

Front cover

5.

Chain guide

6.

Chain tensioner

7.

Spring

8.

Chain tensioner plunger

9.

O-ring

10. Oil ring

11.

O-ring

12.

Intake valve timing control solenoid

valve

13. Intake valve timing control cover

14. Camshaft sprocket (INT)

15. Camshaft sprocket (EXH)

16. O-ring

17. Valve lifter

18. Camshaft (INT)

19. Camshaft (EXH)

20. O-ring

21. Camshaft position sensor (PHASE)

A.

EM-52, "Removal and Installation"

WBIA0833E