Nissan Frontier D40. Manual - part 577

EM-40

< ON-VEHICLE REPAIR >

[QR25DE]

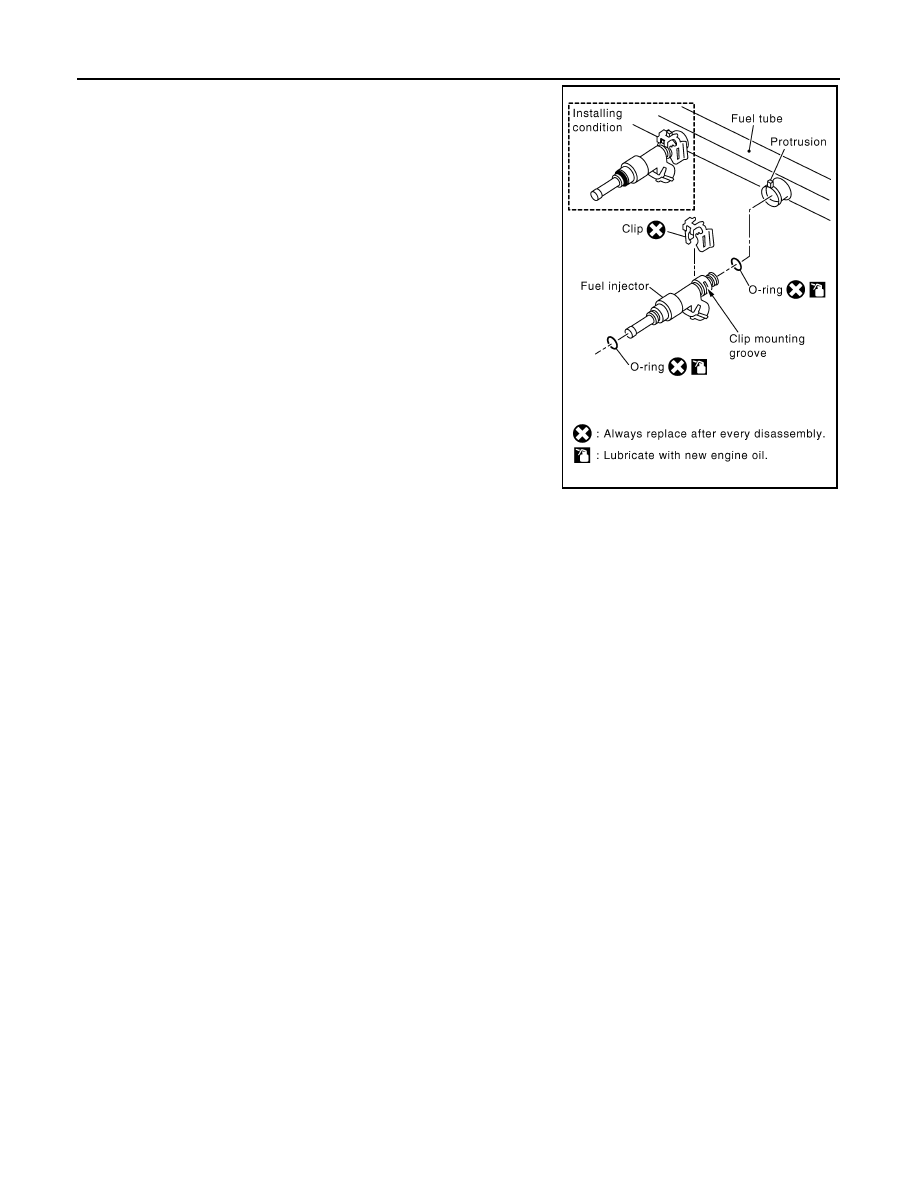

FUEL INJECTOR AND FUEL TUBE

6.

Remove fuel injector from fuel tube as follows:

a.

Carefully open and remove clip.

b.

Remove fuel injector from fuel tube by pulling straight.

CAUTION:

• Be careful with remaining fuel that may leak out from fuel

tube.

• Do not damage fuel injector nozzles during removal.

• Do not bump or drop fuel injectors.

• Do not disassemble fuel injectors.

INSTALLATION

1.

Install new O-rings to fuel injector, paying attention to the following.

CAUTION:

• Upper and lower O-rings are different colors.

• Handle O-ring with bare hands. Do not wear gloves.

• Lubricate O-ring with new engine oil.

• Do not clean O-ring with solvent.

• Make sure that O-ring and its mating part are free of foreign material.

• When installing O-ring, be careful not to scratch it with tool or fingernails.

• Do not twist or stretch O-ring. If O-ring was stretched while it was being attached, allow it to

retract before inserting it into fuel tube.

• Insert new O-ring straight into fuel tube. Do not angle or twist it.

PBIC2999E

Fuel tube side

: Black

Nozzle side

: Green