Nissan Frontier D40. Manual - part 519

P1212 TCS COMMUNICATION LINE

EC-767

< COMPONENT DIAGNOSIS >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P1212 TCS COMMUNICATION LINE

Description

INFOID:0000000005273757

NOTE:

• If DTC P1212 is displayed with DTC UXXXX, first perform the trouble diagnosis for DTC UXXXX.

• If DTC P1212 is displayed with DTC P0607, first perform the trouble diagnosis for DTC P0607. Refer

EC-757, "On Board Diagnosis Logic"

.

This CAN communication line is used to control the smooth engine operation during the TCS operation. Pulse

signals are exchanged between ECM and “ABS actuator and electric unit (control unit)”.

Be sure to erase the malfunction information such as DTC not only for “ABS actuator and electric unit

(control unit)” but also for ECM after TCS related repair.

On Board Diagnosis Logic

INFOID:0000000005273758

Freeze frame data is not stored in the ECM for this self-diagnosis. The MIL will not illuminate for this

self-diagnosis.

DTC Confirmation Procedure

INFOID:0000000005273759

TESTING CONDITION:

Before performing the following procedure, confirm that battery voltage is more than 10.5V at idle.

1.

Start engine and let it idle for at least 10 seconds.

2.

Check 1st trip DTC.

3.

If 1st trip DTC is detected, go to

Diagnosis Procedure

INFOID:0000000005273760

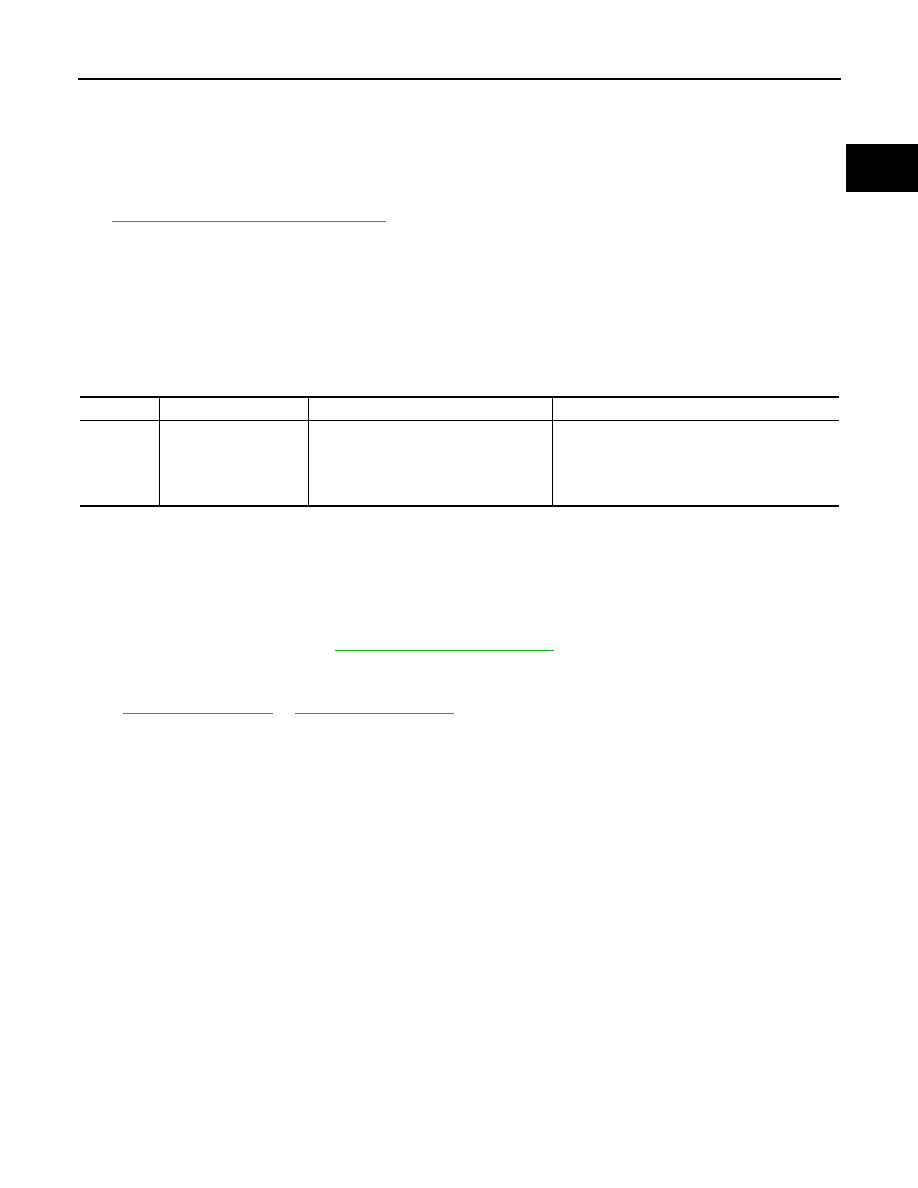

DTC No.

Trouble diagnosis name

DTC detecting condition

Possible cause

P1212

1212

TCS communication line

ECM cannot receive the information from

“ABS actuator and electric unit (control

unit)”.

• Harness or connectors

(The CAN communication line is open or short-

ed.)

• ABS actuator and electric unit (control unit)

• Dead (Weak) battery