Nissan Frontier D40. Manual - part 470

P0102, P0103 MAF SENSOR

EC-571

< COMPONENT DIAGNOSIS >

[VQ40DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

P0102, P0103 MAF SENSOR

Component Description

INFOID:0000000005273531

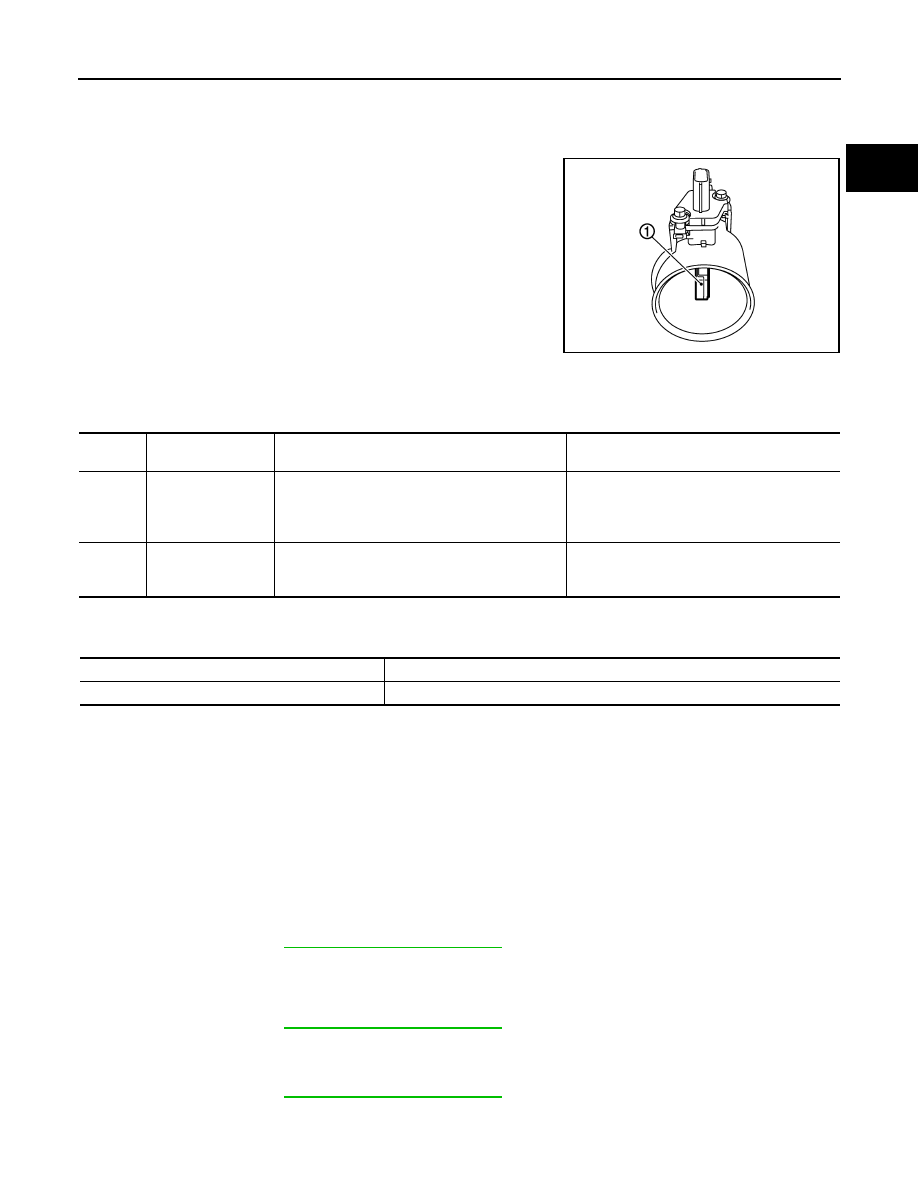

The mass air flow sensor (1) is placed in the stream of intake air. It

measures the intake flow rate by measuring a part of the entire

intake flow. The mass air flow sensor controls the temperature of the

hot wire to a certain amount. The heat generated by the hot wire is

reduced as the intake air flows around it. The more air, the greater

the heat loss.

Therefore, the electric current is supplied to hot wire is changed to

maintain the temperature of the hot wire as air flow increases. The

ECM detects the air flow by means of this current change.

On Board Diagnosis Logic

INFOID:0000000005273532

These self-diagnoses have the one trip detection logic.

FAIL-SAFE MODE

When the malfunction is detected, the ECM enters fail-safe mode and the MIL illuminates.

DTC Confirmation Procedure

INFOID:0000000005273533

NOTE:

If DTC Confirmation Procedure has been previously conducted, always perform the following before conduct-

ing the next step.

1.

Turn ignition switch OFF and wait at least 10 seconds.

2.

Turn ignition switch ON.

3.

Turn ignition switch OFF and wait at least 10 seconds.

PROCEDURE FOR DTC P0102

1.

Start engine and wait at least 5 seconds.

2.

Check DTC.

3.

If DTC is detected, go to

.

PROCEDURE FOR DTC P0103

1.

Turn ignition switch ON and wait at least 5 seconds.

2.

Check DTC.

3.

If DTC is detected, go to

.

If DTC is not detected, go to next step.

4.

Start engine and wait at least 5 seconds.

5.

Check DTC.

6.

If DTC is detected, go to

.

PBIA9559J

DTC No.

Trouble diagnosis

name

DTC detecting condition

Possible cause

P0102

0102

Mass air flow sensor

circuit low input

An excessively low voltage from the sensor is sent

to ECM.

• Harness or connectors

(The sensor circuit is open or shorted.)

• Intake air leaks

• Mass air flow sensor

P0103

0103

Mass air flow sensor

circuit high input

An excessively high voltage from the sensor is

sent to ECM.

• Harness or connectors

(The sensor circuit is open or shorted.)

• Mass air flow sensor

Detected items

Engine operating condition in fail-safe mode

Mass air flow sensor circuit

Engine speed will not rise more than 2,400 rpm due to the fuel cut.