Nissan Frontier D40. Manual - part 442

EVAP CANISTER

EC-459

< ON-VEHICLE REPAIR >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

ON-VEHICLE REPAIR

EVAP CANISTER

Component Inspection

INFOID:0000000005273448

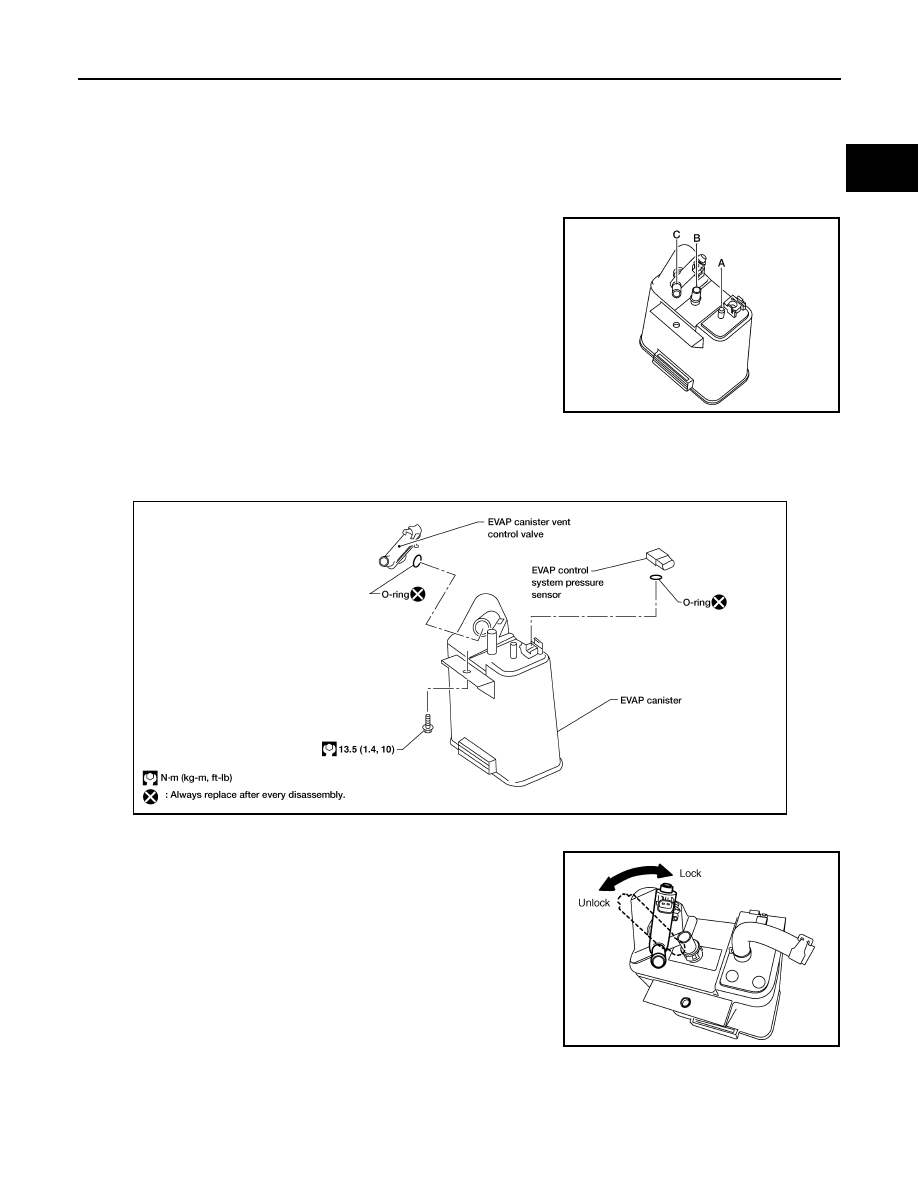

EVAP CANISTER

Check EVAP canister as follows:

1.

Block port B.

2.

Blow air into port A and check that it flows freely out of port C.

3.

Release blocked port B.

4.

Apply vacuum pressure to port B and check that vacuum pres-

sure exists at the ports A and C.

5.

Block port A and B.

6.

Apply pressure to port C and check that there is no leakage.

Removal and Installation

INFOID:0000000005273449

EVAP CANISTER

Tighten EVAP canister as shown in the figure.

EVAP CANISTER VENT CONTROL VALVE

1.

Turn EVAP canister vent control valve counterclockwise.

2.

Remove the EVAP canister vent control valve.

Do not reuse the O-ring, replace it with a new one.

BBIA0639E

BBIA0566E

BBIA0567E