Nissan Frontier D40. Manual - part 421

FUEL INJECTOR

EC-375

< COMPONENT DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

FUEL INJECTOR

Component Description

INFOID:0000000005273415

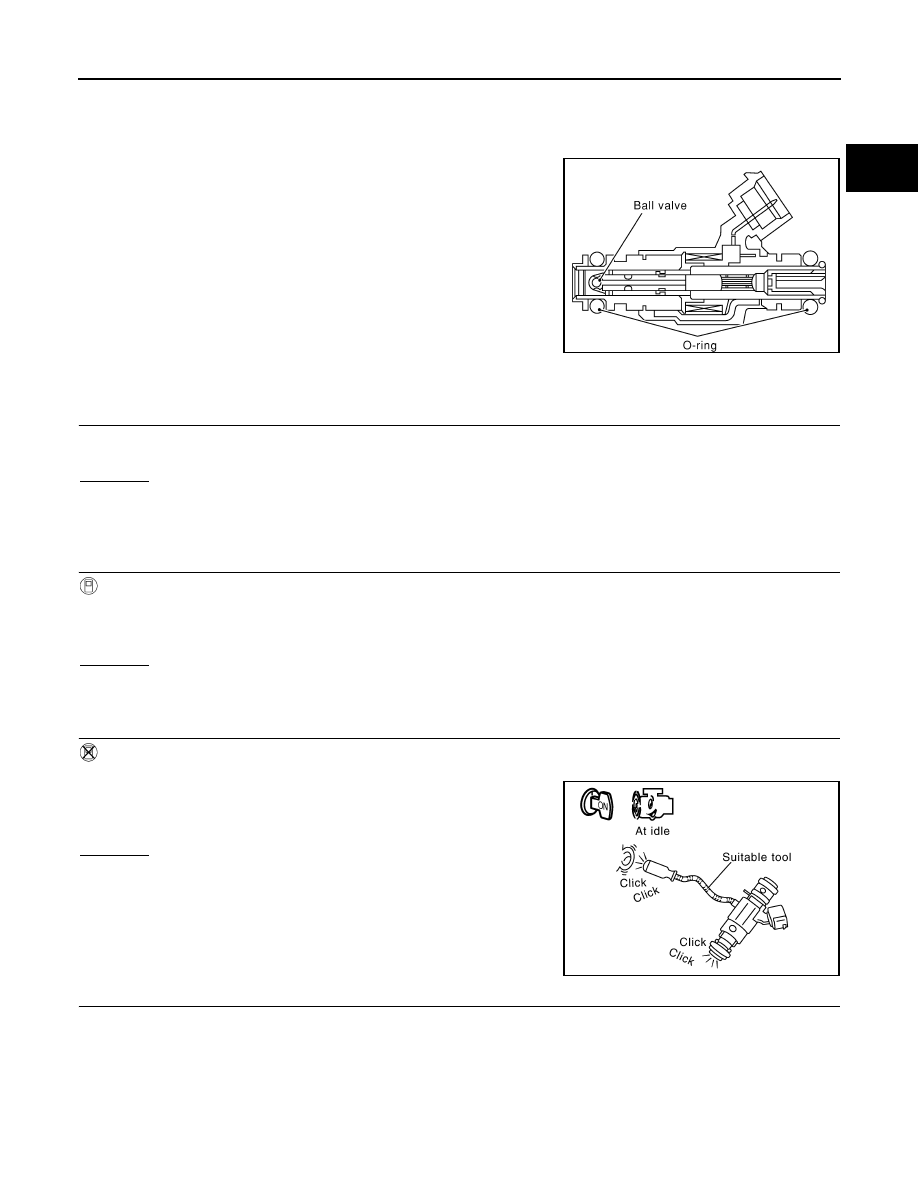

The fuel injector is a small, precise solenoid valve. When the ECM

supplies a ground to the fuel injector circuit, the coil in the fuel injec-

tor is energized. The energized coil pulls the ball valve back and

allows fuel to flow through the fuel injector into the intake manifold.

The amount of fuel injected depends upon the injection pulse dura-

tion. Pulse duration is the length of time the fuel injector remains

open. The ECM controls the injection pulse duration based on

engine fuel needs.

Diagnosis Procedure

INFOID:0000000005273416

1.

INSPECTION START

Turn ignition switch to START.

Is any cylinder ignited?

Yes or No

Yes (With CONSULT-III)>>GO TO 2.

Yes (Without CONSULT-III)>>GO TO 3.

No

>> GO TO 4.

2.

CHECK OVERALL FUNCTION

With CONSULT-III

1.

Start engine.

2.

Perform “POWER BALANCE” in “ACTIVE TEST” mode with CONSULT-III.

3.

Make sure that each circuit produces a momentary engine speed drop.

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 4.

3.

CHECK FUNCTION OF FUEL INJECTOR

Without CONSULT-III

1.

Start engine.

2.

Listen to each fuel injector operating sound.

OK or NG

OK

>> INSPECTION END

NG

>> GO TO 4.

4.

CHECK FUEL INJECTOR POWER SUPPLY CIRCUIT

1.

Turn ignition switch OFF.

SEF375Z

Clicking noise should exist.

PBIB1986E