Nissan Frontier D40. Manual - part 419

P2A00 A/F SENSOR 1

EC-367

< COMPONENT DIAGNOSIS >

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Replace air fuel ratio (A/F) sensor 1.

CAUTION:

• Discard any air fuel ratio (A/F) sensor which has been dropped from a height of more than 0.5 m

(19.7 in) onto a hard surface such as a concrete floor; use a new one.

• Before installing new air fuel ratio (A/F) sensor, clean exhaust system threads using Heated Oxygen

Sensor Thread Cleaner [commercial service tool (J-43897-18 or J-43897-12)] and approved anti-seize

lubricant (commercial service tool).

>> GO TO 12.

12.

CONFIRM A/F ADJUSTMENT DATA

1.

Turn ignition switch ON.

2.

Select “A/F ADJ-B1” in “DATA MONITOR” mode with CONSULT-III.

3.

Make sure that “0.000” is displayed on CONSULT-III screen.

OK or NG

OK

>> INSPECTION END.

NG

>> GO TO 13.

13.

CLEAR THE SELF-LEARNING DATA

With CONSULT-III

1.

Start engine and warm it up to normal operating temperature.

2.

Select “SELF-LEARNING CONT” in “WORK SUPPORT” mode with CONSULT-III.

3.

Clear the self-learning control coefficient by touching “CLEAR”.

Without CONSULT-III

1.

Start engine and warm it up to normal operating temperature.

2.

Turn ignition switch OFF.

3.

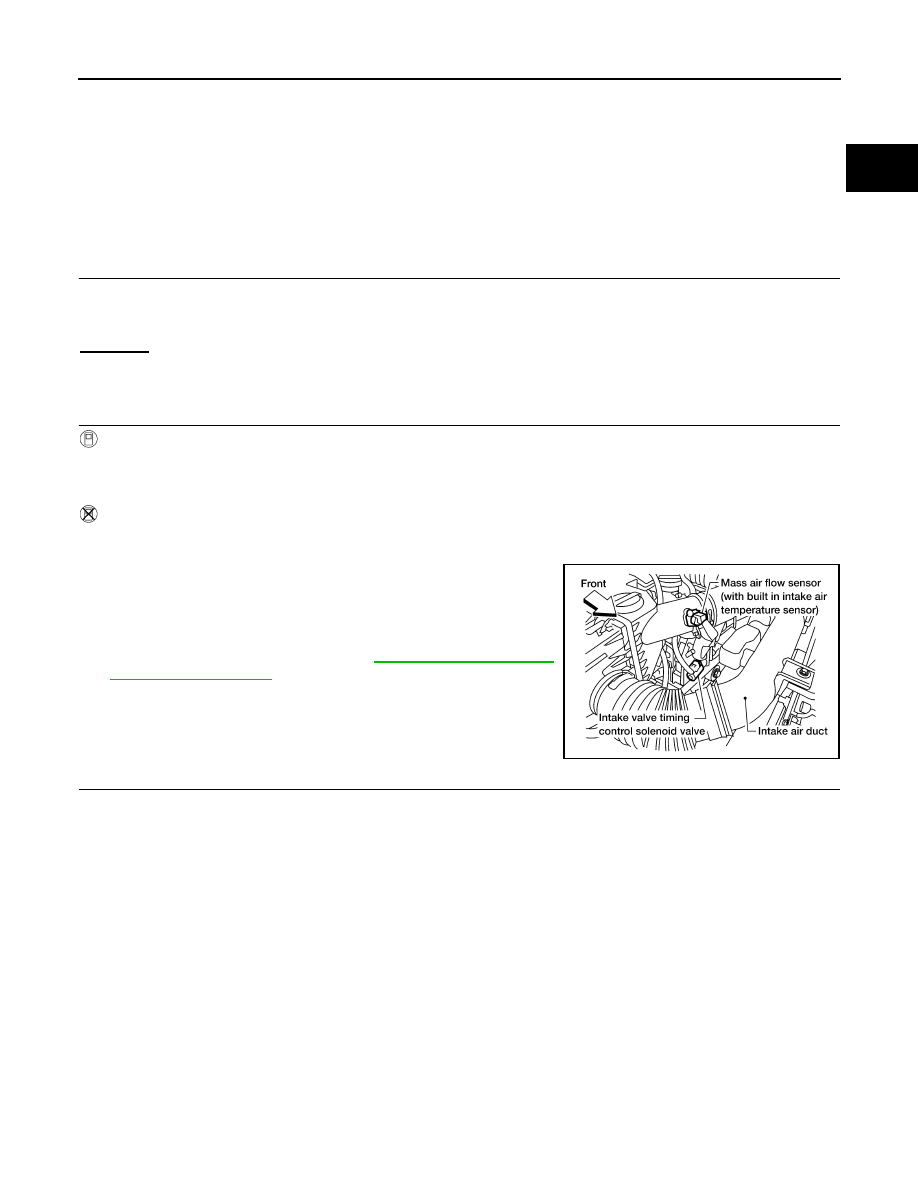

Disconnect mass air flow sensor harness connector.

4.

Restart engine and let it idle for at least 5 seconds.

5.

Stop engine and reconnect mass air flow sensor harness con-

nector.

6.

Make sure DTC P0102 is displayed.

7.

Erase the DTC memory. Refer to

8.

Make sure DTC P0000 is displayed.

>> GO TO 14.

14.

CONFIRM A/F ADJUSTMENT DATA

1.

Turn ignition switch OFF and then ON.

2.

Select “A/F ADJ-B1” in “DATA MONITOR” mode with CONSULT-III.

3.

Make sure that “0.000” is displayed on CONSULT-III screen.

>> INSPECTION END

BBIA0622E