Nissan Frontier D40. Manual - part 192

SERVICE DATA AND SPECIFICATIONS (SDS)

CO-29

< SERVICE DATA AND SPECIFICATIONS (SDS)

[QR25DE]

C

D

E

F

G

H

I

J

K

L

M

A

CO

N

P

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Standard and Limit

INFOID:0000000005276100

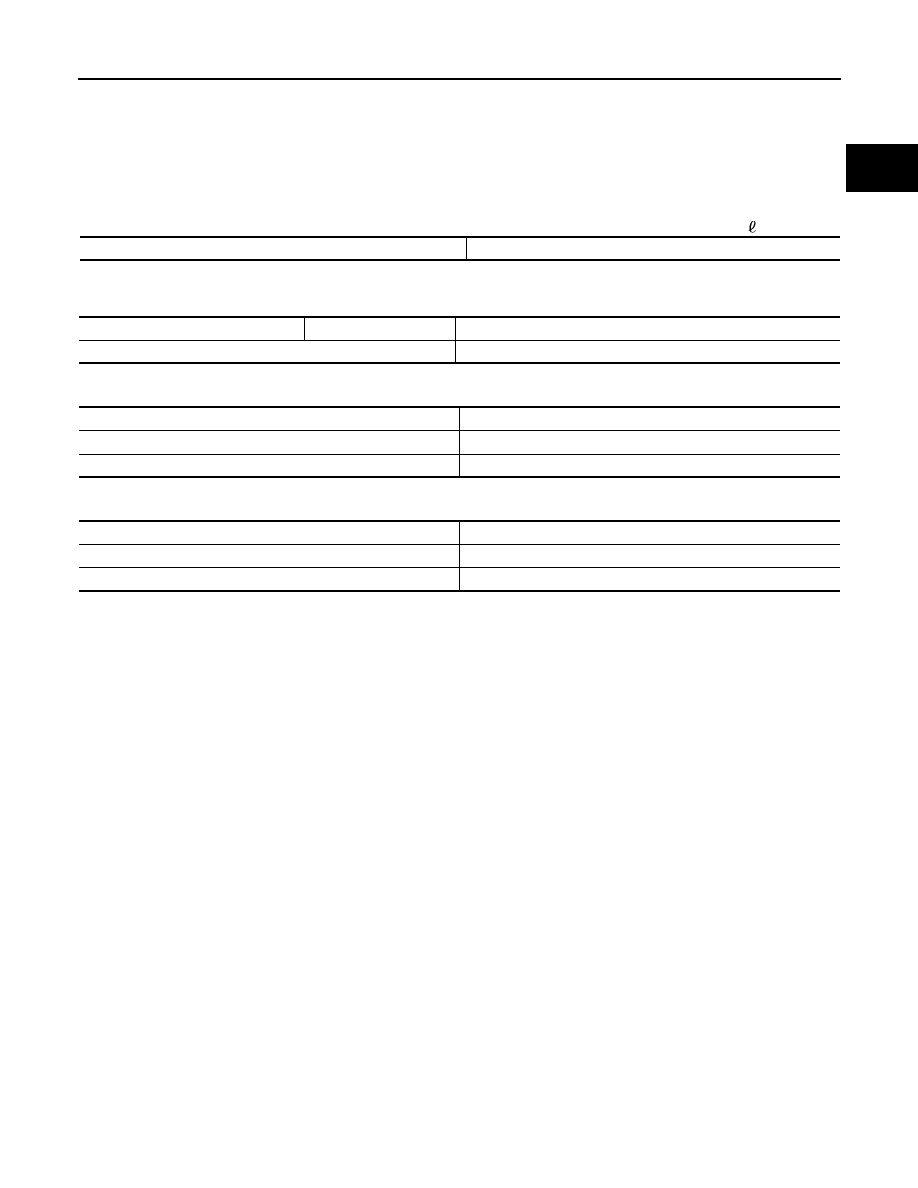

ENGINE COOLANT CAPACITY (APPROXIMATE)

Unit:

(US qt, Imp qt)

RADIATOR

Unit: kPa (kg/cm

2

, psi)

THERMOSTAT

WATER CONTROL VALVE

Engine coolant capacity (With reservoir tank at “MAX” level)

9.4 (10, 8-1/4)

Cap relief pressure

Standard

98 - 118 (1.0 - 1.2, 14- 17)

Leakage test pressure

137 (1.4, 20)

Valve opening temperature

80.5 - 83.5

°

C (177 - 182

°

F)

Full-open lift amount

8 mm/ 95

°

C (0.315 in/ 203

°

F)

Valve closing temperature

77

°

C (171

°

F)

Valve opening temperature

93.5 - 96.5

°

C (200 - 206

°

F)

Full-open lift amount

More than 8 mm/ 108

°

C (0.315 in/ 226

°

F)

Valve closing temperature

90

°

C (194

°

F) or higher