Nissan Titan. Manual - part 219

P0102, P0103 MAF SENSOR

EC-177

< DTC/CIRCUIT DIAGNOSIS >

[VK56DE]

C

D

E

F

G

H

I

J

K

L

M

A

EC

N

P

O

Diagnosis Procedure

INFOID:0000000009886574

1.

INSPECTION START

Which malfunction (P0102 or P0103) is duplicated?

P0102 or P0103

P0102 >> GO TO 2.

P0103 >> GO TO 3.

2.

CHECK INTAKE SYSTEM

Check the following for connection.

• Air duct

• Vacuum hoses

• Intake air passage between air duct to intake manifold

OK or NG

OK

>> GO TO 3.

NG

>> Reconnect the parts.

3.

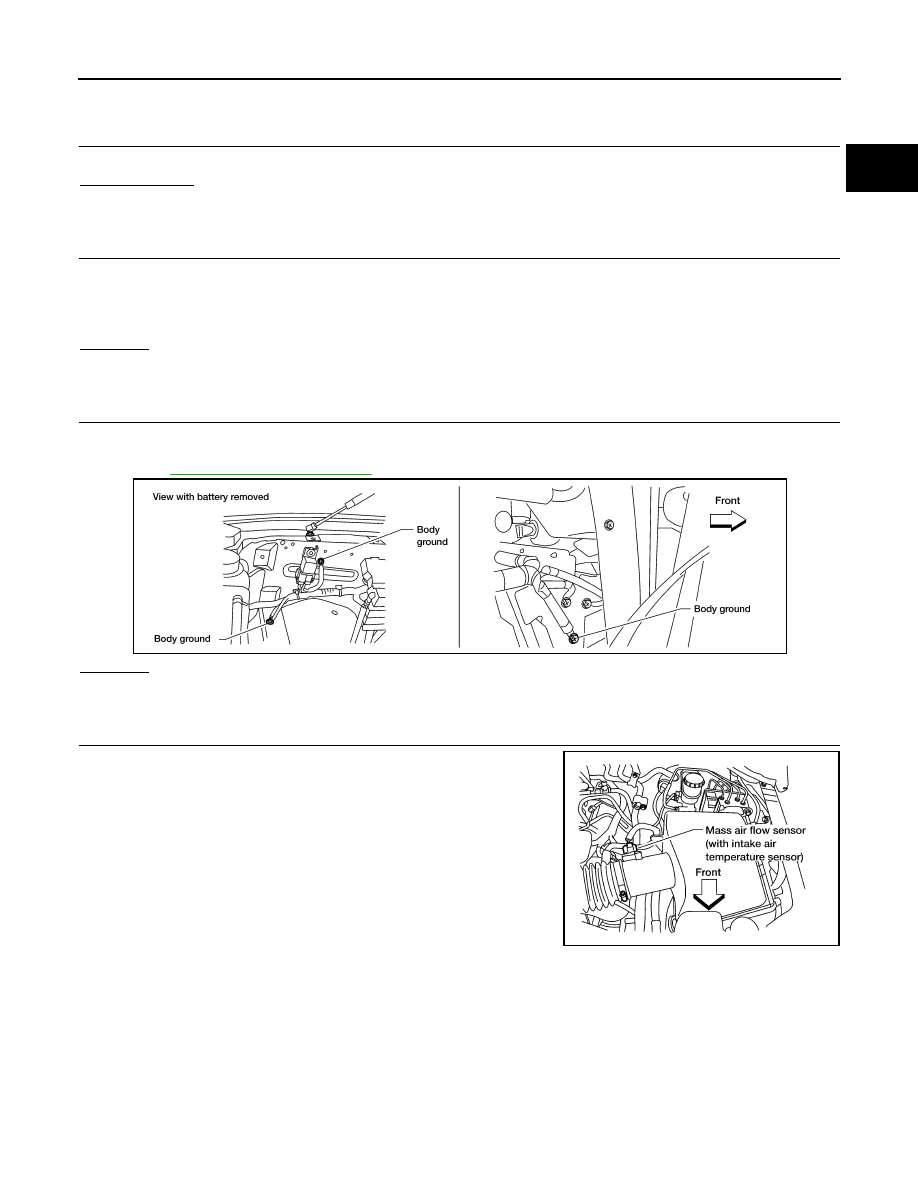

RETIGHTEN GROUND SCREWS

1. Turn ignition switch OFF.

2. Loosen and retighten three ground screws on the body.

OK or NG

OK

>> GO TO 4.

NG

>> Repair or replace ground connections.

4.

CHECK MAF SENSOR POWER SUPPLY CIRCUIT

1. Disconnect mass air flow (MAF) sensor harness connector.

2. Turn ignition switch ON.

BBIA0354E

BBIA0368E