Nissan Titan. Manual - part 173

DLN-264

< UNIT DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: M226 (ELD) ]

REAR FINAL DRIVE

CAUTION:

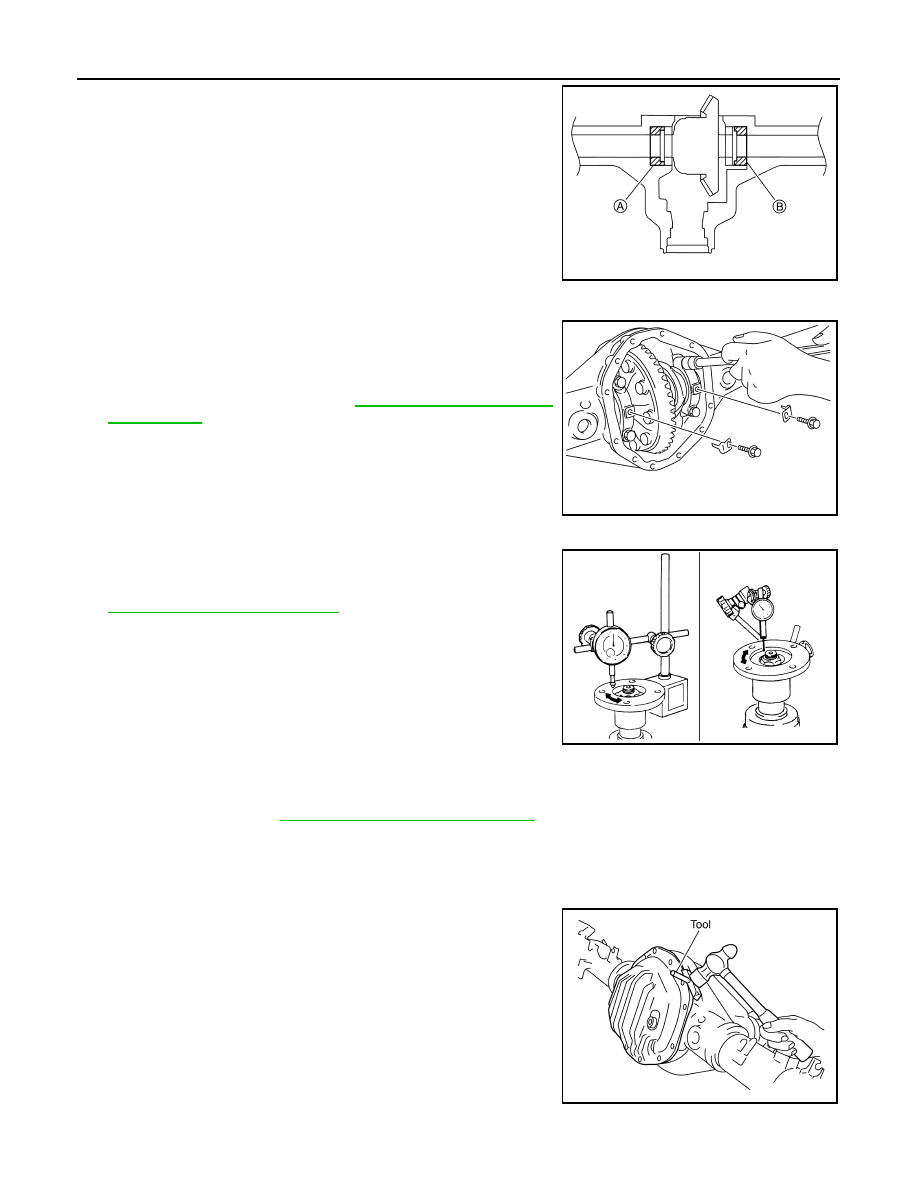

Do not change the side bearing side bearing adjusters by

different amounts as it will change the side bearing preload

torque.

d. Tighten side bearing cap bolts to the specified torque.

e. Install adjuster lock plate and tighten to the specified torque.

CAUTION:

Check tooth contact and total preload torque after adjusting

side bearing adjuster. Refer to

Companion Flange Runout

1. Rotate companion flange and check for runout on the compan-

ion flange face (inner side of the bolt holes) and companion

flange inner side (socket diameter) using suitable tool. Refer to

DLN-271, "General Specification"

.

2. If the runout is outside the runout limit, follow the procedure

below to adjust.

a. Rotate the companion flange on the drive pinion by 90

°, 180°

and 270

° while checking for the position where the runout is

minimum.

b. If the runout is still outside of the runout limit after the companion

flange has been rotated on the drive pinion, possible cause

could be an assembly malfunction of drive pinion and drive pin-

ion bearing or a malfunctioning drive pinion bearing.

c.

If the runout is still outside of the runout limit after replacing the companion flange. Replace the rear final

drive assembly. Refer to

DLN-259, "Removal and Installation"

DISASSEMBLY

Differential Assembly

1. Remove carrier cover bolts.

2. Remove carrier cover using Tool.

CAUTION:

• Do not damage the mating surface.

• Do not insert flat-bladed screwdriver, this will damage the

mating surface.

If the backlash is greater than specification:

Loosen side bearing adjuster (A) and tighten side

bearing adjuster (B) by the same amount.

If the backlash is less than specification:

Loosen side bearing adjuster (B) and tighten side

bearing adjuster (A) by the same amount.

PDIA0330E

PDIA0331E

SDIA2078E

Tool number

: KV10111100 (J-37228)

PDIA1041E