Nissan Titan. Manual - part 159

DLN-208

< BASIC INSPECTION >

[REAR FINAL DRIVE: M226 (ELD) ]

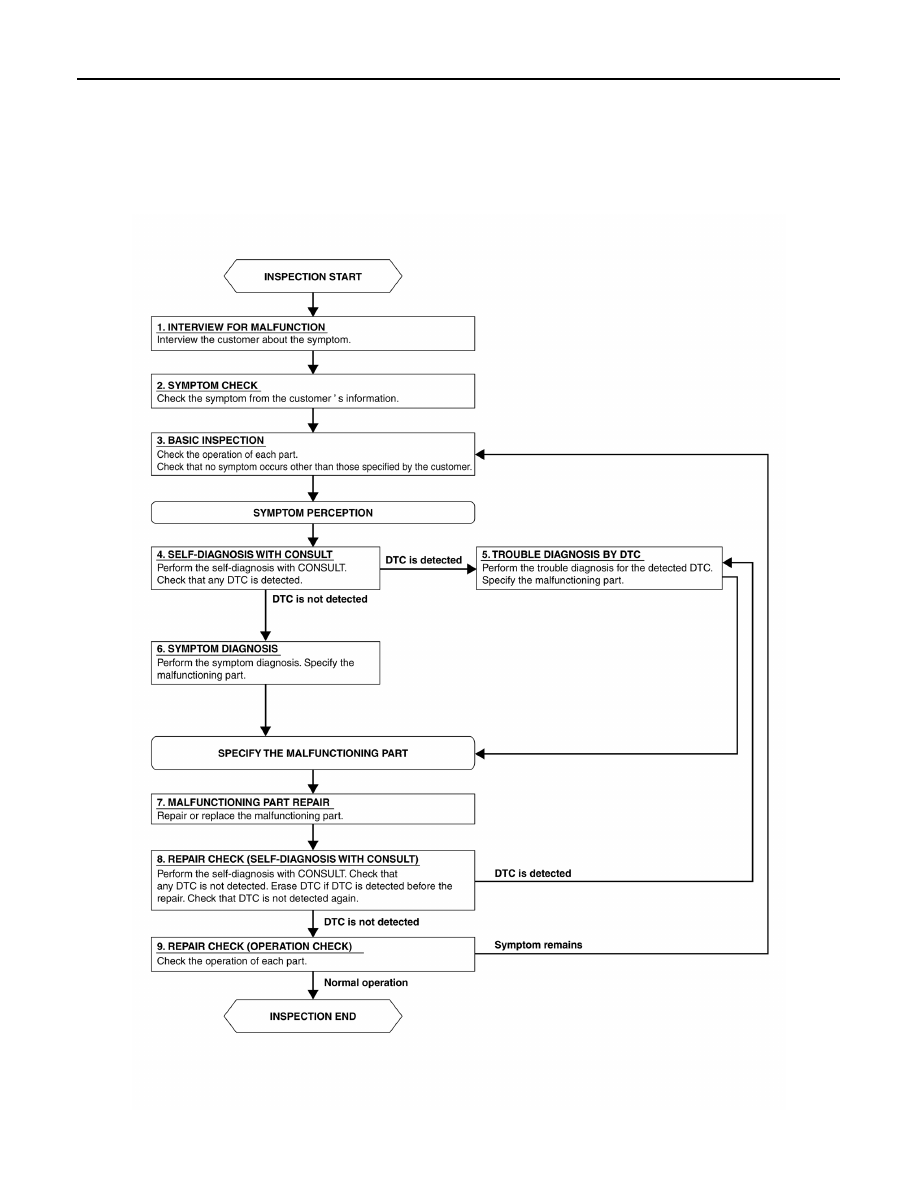

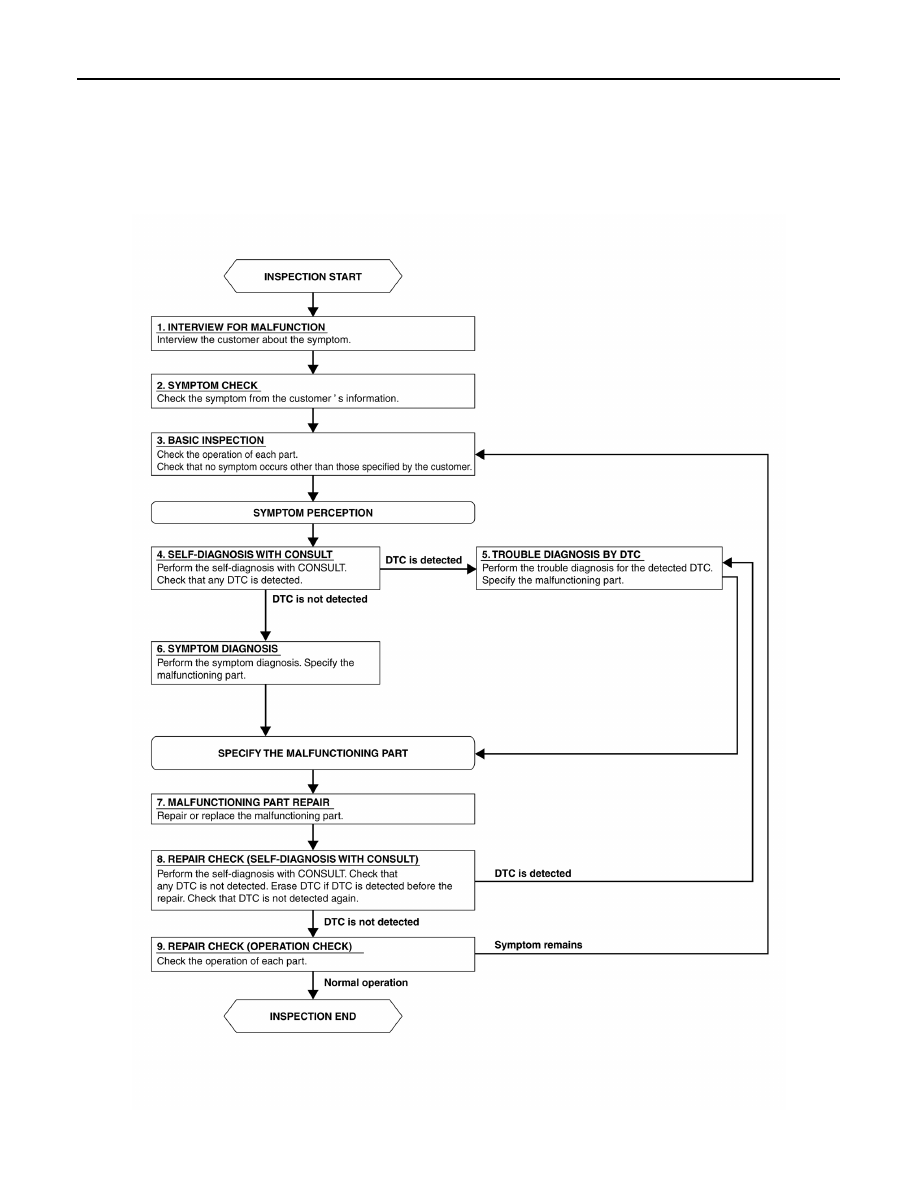

DIAGNOSIS AND REPAIR WORKFLOW

BASIC INSPECTION

DIAGNOSIS AND REPAIR WORKFLOW

Work Flow

INFOID:0000000009886097

OVERALL SEQUENCE

DETAILED FLOW

AWEIA0214GB

|

|

|

DLN-208 < BASIC INSPECTION > [REAR FINAL DRIVE: M226 (ELD) ] DIAGNOSIS AND REPAIR WORKFLOW BASIC INSPECTION DIAGNOSIS AND REPAIR WORKFLOW Work Flow INFOID:0000000009886097 OVERALL SEQUENCE DETAILED FLOW AWEIA0214GB |