Nissan Titan. Manual - part 156

DLN-196

< UNIT REMOVAL AND INSTALLATION >

[REAR FINAL DRIVE: M226 ]

REAR FINAL DRIVE

UNIT REMOVAL AND INSTALLATION

REAR FINAL DRIVE

Removal and Installation

INFOID:0000000009886093

REMOVAL

CAUTION:

• Do not damage spline, companion flange and front oil seal when removing propeller shaft.

• Before removing final drive assembly or rear axle assembly, disconnect ABS sensor harness con-

nector from the assembly and move it away from final drive/rear axle assembly area. Failure to do so

may result in sensor wires being damaged and sensor becoming inoperative.

1. Remove the rear wheels and tires using power tool. Refer to

.

2. Remove rear brake disc rotors. Refer to

BR-36, "Removal and Installation of Brake Caliper and Disc

3. Remove the rear propeller shaft. Refer to

DLN-139, "Removal and Installation"

(2S1410),

4. Disconnect the following components from the rear final drive assembly.

• Brake tube block connectors. Refer to

BR-22, "Removal and Installation of Rear Brake Piping and Brake

• ABS sensor wire harness. Refer to

BRC-113, "Removal and Installation"

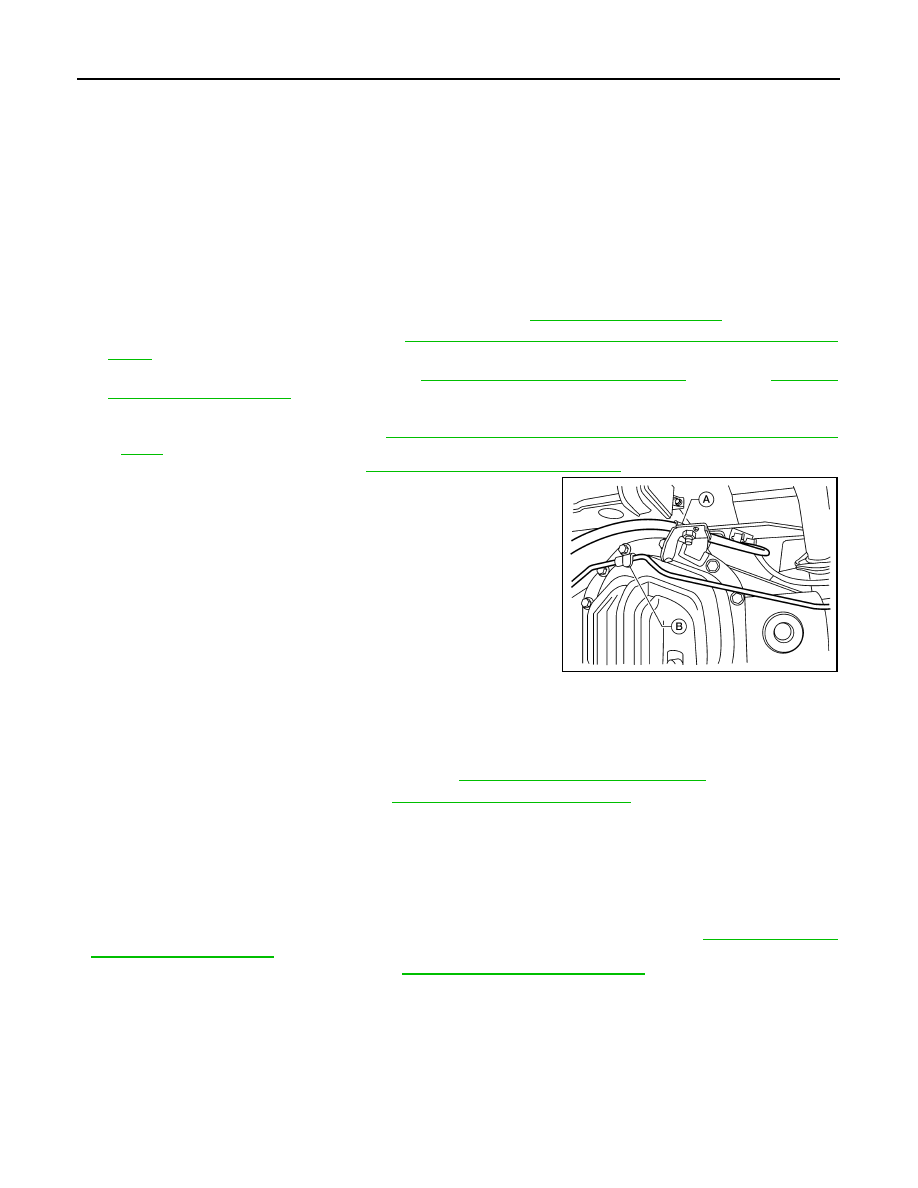

• Parking brake cable (A).

• Brake tube (B).

5. Disconnect brake hose from brake tube at the mounting clip on top of rear final drive assembly. Then

remove the metal clip to disconnect brake line from the mounting clip on top of the rear final drive assem-

bly.

6. Support rear final drive assembly using a suitable jack.

7. Remove rear shock absorber lower bolts. Refer to

RSU-10, "Removal and Installation"

8. Remove leaf spring U-bolt nuts. Refer to

RSU-7, "Removal and Installation"

9. Remove rear final drive assembly.

CAUTION:

Secure rear final drive assembly to the jack while removing it.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Check the rear final drive assembly differential gear oil after installation. Refer to

• Bleed the air from brake system. Refer to

BR-16, "Bleeding Brake System"

.

WDIA0330E