Nissan Titan A60. Manual - part 731

MWI-38

< DTC/CIRCUIT DIAGNOSIS >

FUEL LEVEL SENSOR SIGNAL CIRCUIT

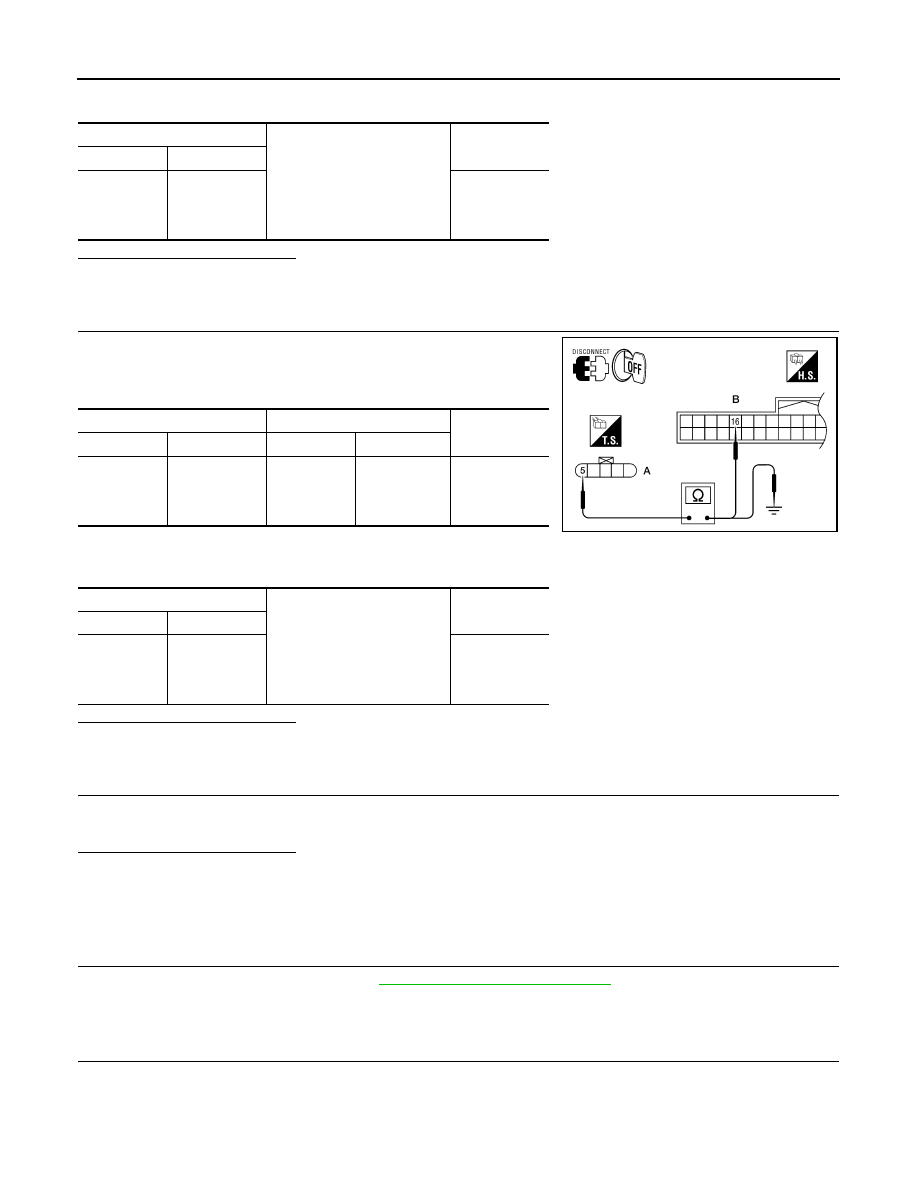

3. Check continuity between fuel level sensor unit and fuel pump harness connector (A) and ground.

Is the inspection result normal?

YES

>> GO TO 3

NO

>> Repair harness or connector.

3.

CHECK FUEL LEVEL SENSOR UNIT GROUND CIRCUIT

1. Check continuity between combination meter harness connector

(B) and fuel level sensor unit and fuel pump harness connector

(A).

2. Check continuity between fuel level sensor unit and fuel pump

harness connector (A) and ground.

Is the inspection result normal?

YES

>> GO TO 4

NO

>> Repair harness or connector.

4.

CHECK INSTALLATION CONDITION

Check fuel level sensor unit installation, and check whether the float arm interferes or binds with any of the

internal components in the fuel tank.

Is the inspection result normal?

YES

>> Inspection End.

NO

>> Install the fuel level sensor unit properly.

Component Inspection

INFOID:0000000006164921

1.

REMOVE FUEL LEVEL SENSOR UNIT

Remove the fuel level sensor unit. Refer to

FL-11, "Removal and Installation"

>> GO TO 2

2.

CHECK FUEL LEVEL SENSOR UNIT AND FUEL PUMP

A

Ground

Continuity

Connector

Terminal

C7 (with

Flexible Fuel)

C5 (without

Flexible Fuel)

2

No

A

B

Continuity

Connector

Terminal

Connector

Terminal

C7 (with

Flexible Fuel)

C5 (without

Flexible Fuel)

5

M24

16

Yes

A

Ground

Continuity

Connector

Terminal

C7 (with

Flexible Fuel)

C5 (without

Flexible Fuel)

5

No

WKIA4618E