Nissan Titan A60. Manual - part 704

LU-14

< REMOVAL AND INSTALLATION >

OIL PUMP

OIL PUMP

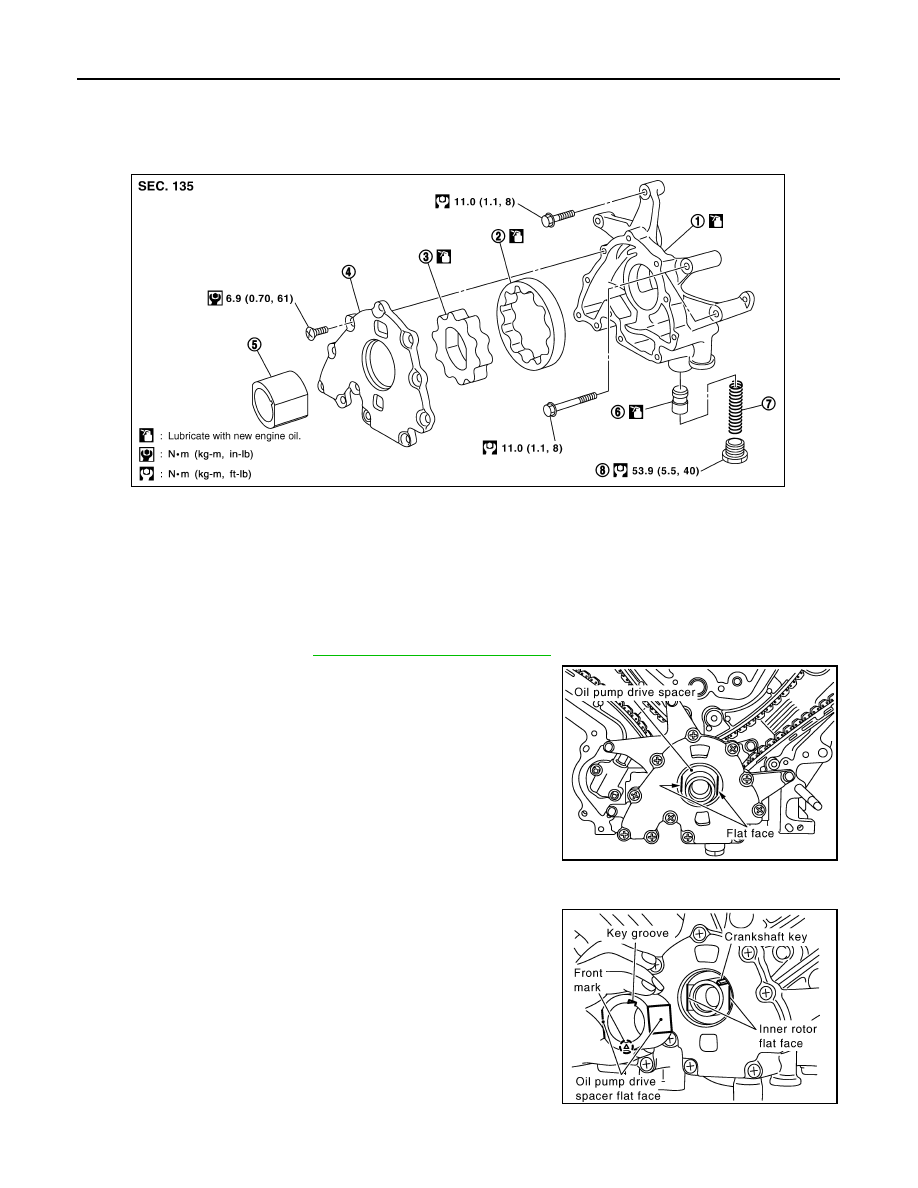

Exploded View

INFOID:0000000006158409

Removal and Installation

INFOID:0000000006158410

REMOVAL

1. Remove front cover. Refer to

EM-48, "Removal and Installation"

2. Remove the oil pump drive spacer.

3. Remove the oil pump.

INSTALLATION

Installation is in the reverse order of removal.

• When inserting the oil pump drive spacer, align the crankshaft key

and the flat face of the inner rotor.

• If they are not aligned, rotate the oil pump inner rotor by hand.

• Make sure that each part is aligned and tap lightly until it reaches

the end.

INSPECTION AFTER INSTALLATION

1.

Oil pump body

2.

Outer rotor

3.

Inner rotor

4.

Oil pump cover

5.

Oil pump drive spacer

6.

Regulator valve

7.

Regulator spring

8.

Regulator plug

WBIA0415E

KBIA2512E

KBIA2490E