Nissan Titan A60. Manual - part 533

PREPARATION

FAX-3

< PREPARATION >

C

E

F

G

H

I

J

K

L

M

A

B

FAX

N

O

P

PREPARATION

PREPARATION

Special Service Tool

INFOID:0000000006161620

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service Tool

INFOID:0000000006161621

Tool number

(Kent-Moore No.)

Tool name

Description

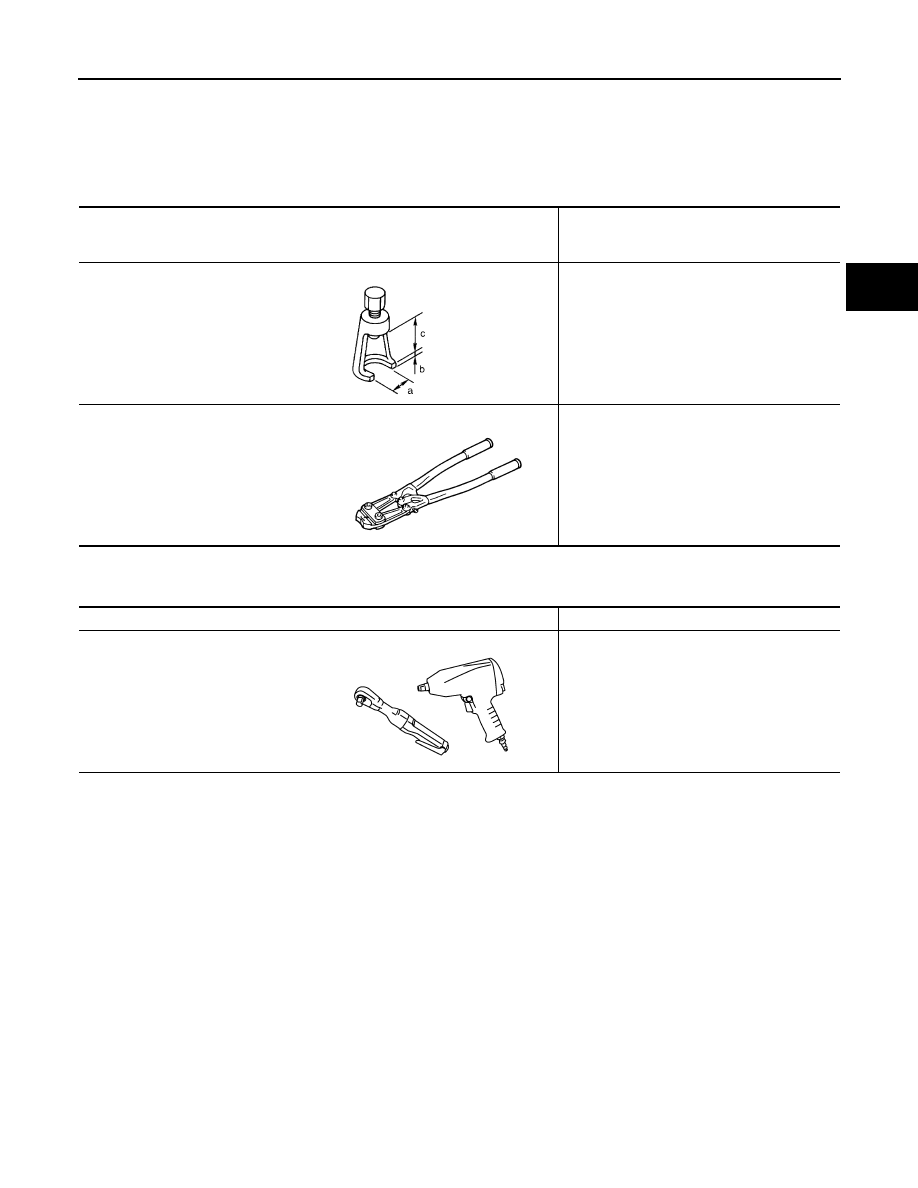

ST29020001

(J-24319-01)

Gear arm puller

Removing ball joint for steering knuckle

a: 34 mm (1.34 in)

b: 6.5 mm (0.256 in)

c: 61.5 mm (2.421 in)

KV40107300

(

—

)

Boot band crimping tool

Installing boot bands

NT694

ZZA1229D

Tool name

Description

Power tools

Removing bolts and nuts

PBIC0190E