Nissan Titan A60. Manual - part 477

ENGINE UNIT

EM-93

< UNIT DISASSEMBLY AND ASSEMBLY >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

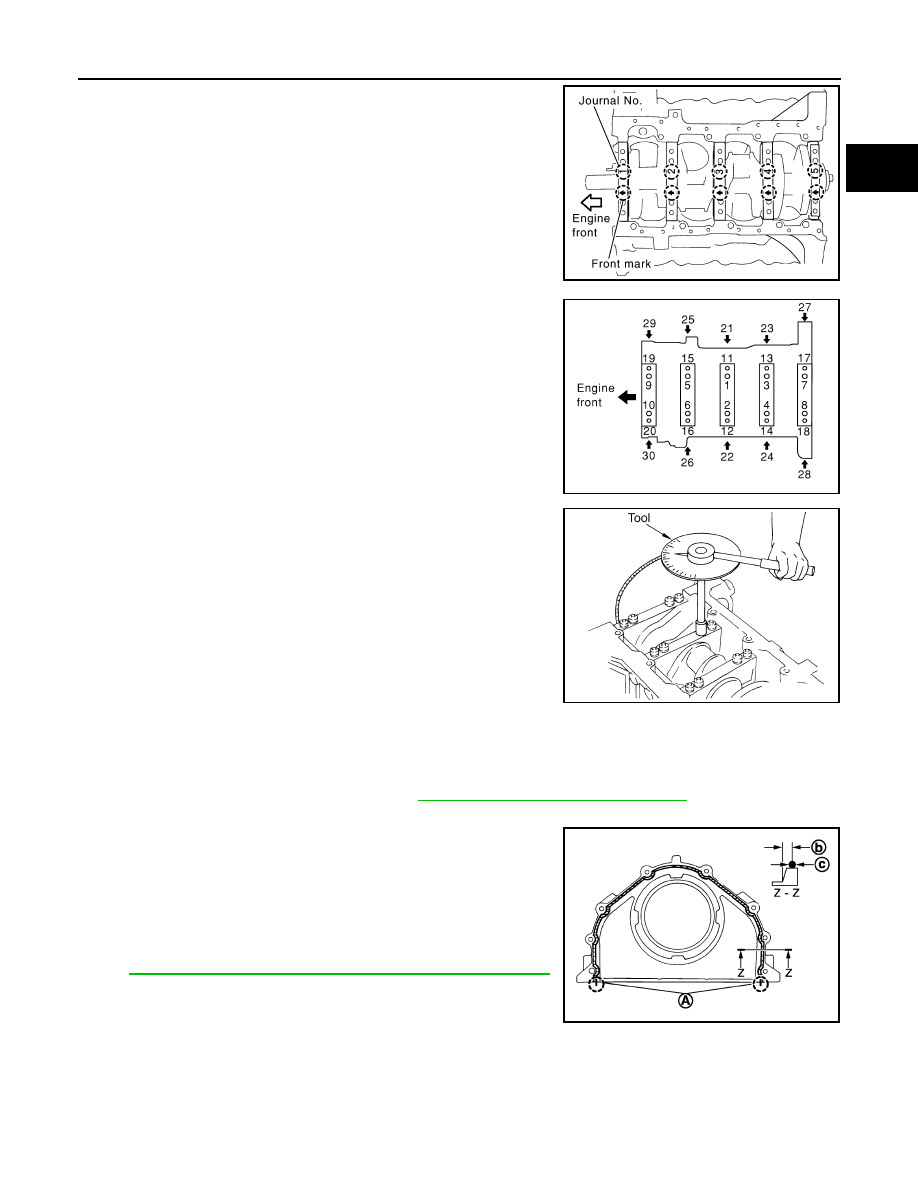

6. Install main bearing caps.

• Align the identification number to the journal position to install.

• Install it with the front mark (indicated by the arrow) facing the

front of engine.

• Tap caps lightly to seat them in the installation position.

7. Follow the steps below to tighten each main bearing cap bolt.

a. Apply engine oil to threads and seating surfaces of bolts, and

tighten all bolts temporarily.

b. Measure tightening angle using Tool.

CAUTION:

Measure tightening angle using Tool. Do not measure visu-

ally.

• Rotate crankshaft by hand after bolts are tightened. Check if it rotates smoothly.

• Check crankshaft side clearance. Refer to

EM-96, "Inspection After Disassembly"

8. Install rear oil seal retainer.

• Apply a continuous bead of liquid gasket using Tool to rear oil

seal retainer as shown.

Use Genuine RTV Silicone Sealant or an equivalent. Refer

GI-15, "Recommended Chemical Products and Sealants"

KBIA2533E

Main bearing cap bolts in

order of 1 to 10

: 39.2 N·m (4.0 kg-m, 29 ft-lb)

Main bearing cap sub

bolts in order of 11 to 20

: 29.4 N·m (3.0 kg-m, 22 ft-lb)

PBIC0090E

Tool number

: KV10112100 (BT-8653-A)

Main bearing cap bolts in

order of 1 to 10

: 40

°

Main bearing cap sub bolts

in order of 11 to 20

: 30

°

Side bolts in order of 21 to

30

: 49 N·m (5.0 kg-m, 36 ft-lb)

A

: Protrusion

b

: 4.0 - 5.6 mm (0.157 - 0.220 in)

c

: 3.4 - 4.4 mm (0.134 - 0.173 in)

Tool number

: WS39930000 ( — )

WBIA0597E

AWBIA0880ZZ