Nissan Titan A60. Manual - part 475

ENGINE ASSEMBLY

EM-85

< UNIT REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

2. Drain the engine coolant. Refer to

CO-11, "Changing Engine Coolant"

3. Drain the engine oil. Refer to

.

4. Disconnect the battery negative terminal. Refer to

PG-76, "Removal and Installation"

5. Remove the engine hood. Refer to

DLK-118, "Removal and Installation of Hood Assembly"

.

6. Remove the cowl extension. Refer to

EXT-20, "Removal and Installation"

7. Remove the engine room cover, if equipped.

8. Remove the air duct and air cleaner case assembly. Refer to

EM-25, "Removal and Installation"

.

9. Remove the radiator assembly and hoses. Refer to

CO-16, "Removal and Installation"

.

10. Remove the drive belt. Refer to

EM-13, "Removal and Installation"

.

11. Remove the fan blade. Refer to

CO-19, "Removal and Installation (Crankshaft Driven Type)"

12. Disconnect the engine room harness from the fuse box and set it aside.

13. Disconnect the ECM.

14. Disconnect the engine room harness from the engine side and set it aside.

15. Disconnect the engine harness grounds.

16. Disconnect the power steering reservoir tank from the engine and move it aside.

17. Disconnect the power steering oil pump from the engine. Move it aside and secure it using suitable wire or

ST-19, "Removal and Installation"

18. Remove the A/C compressor bolts and set the compressor aside. Refer to

.

19. Disconnect the brake booster vacuum line.

20. Disconnect the EVAP line.

21. Disconnect the fuel hose at the engine side connection. Refer to

EM-41, "Removal and Installation"

.

NOTE:

Cap or plug opening(s) to prevent fluid from spilling.

22. Disconnect the heater hoses at the cowl, and install plugs to avoid leakage of engine coolant.

NOTE:

Cap or plug opening(s) to prevent fluid from spilling.

23. Remove the A/T oil level indicator and indicator tube upper bolts.

24. Remove the front final drive assembly (4WD only). Refer to

DLN-169, "Removal and Installation"

NOTE:

Cap or plug opening(s) to prevent fluid from spilling.

25. Remove the exhaust manifolds. Refer to

EM-30, "Removal and Installation"

.

CAUTION:

Temporarily re-install engine mounts before removing A/T.

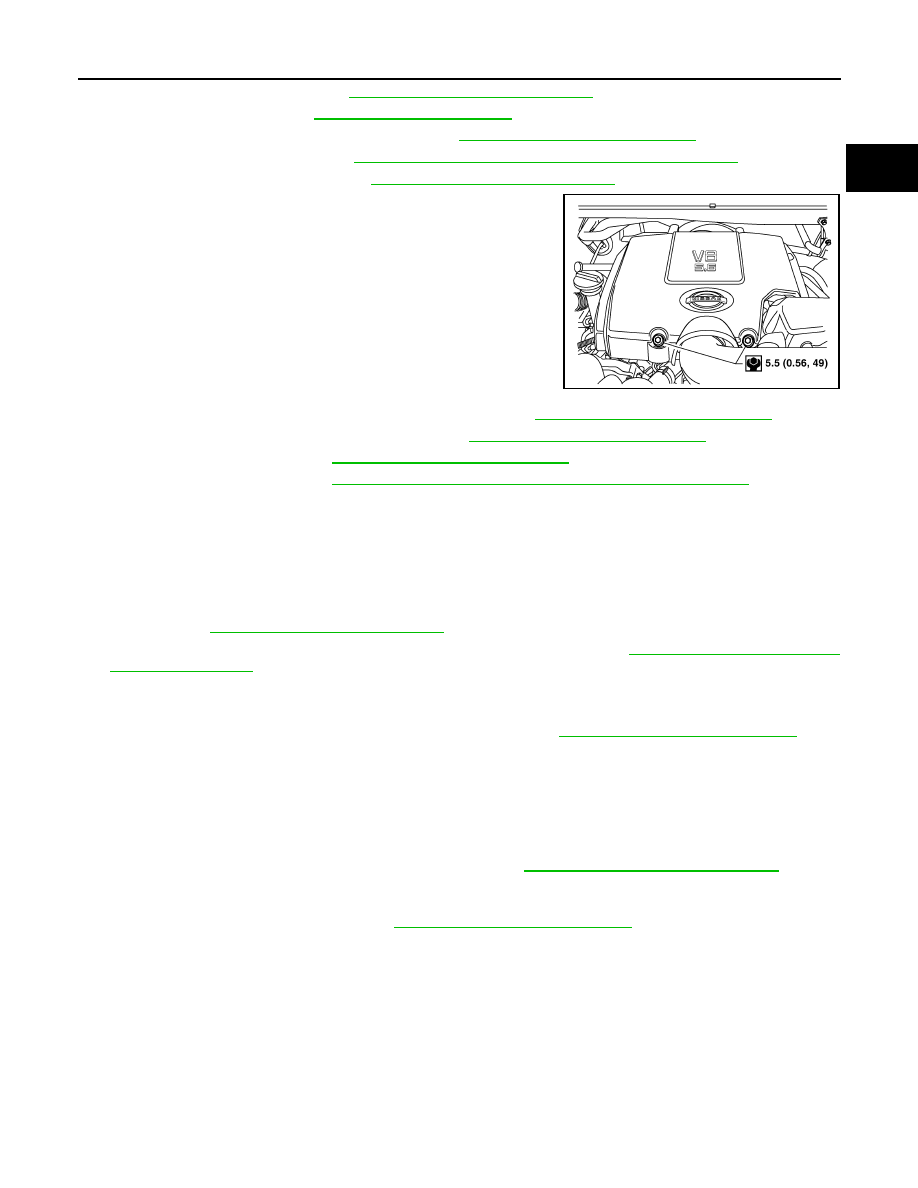

WBIA0795E