Nissan Titan A60. Manual - part 472

OIL SEAL

EM-73

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

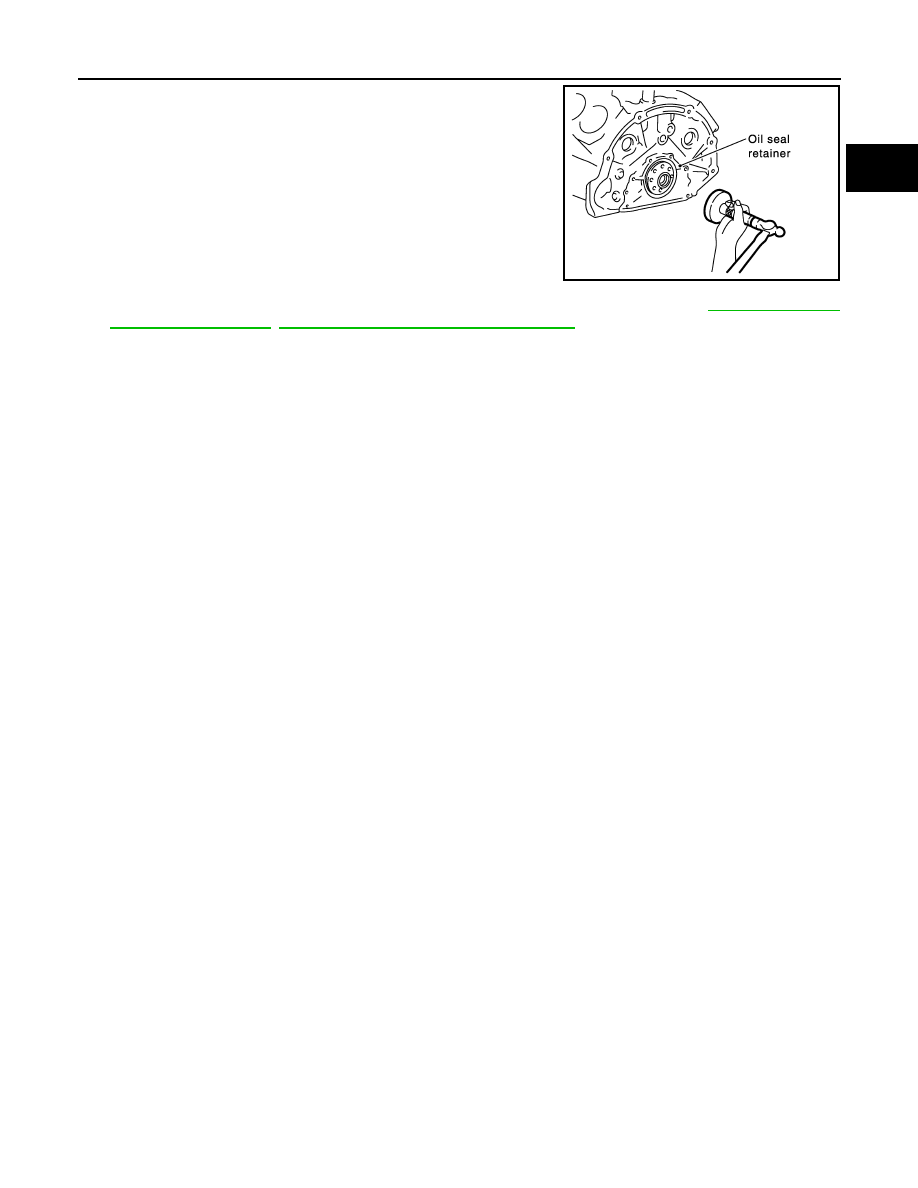

• Press-fit the rear oil seal using suitable tool.

CAUTION:

• Do not damage the crankshaft or cylinder block.

• Press-fit the oil seal straight to avoid causing burrs or

tilting.

• Do not touch grease applied onto the oil seal lip.

• Do not damage or scratch the outer circumference of

the rear oil seal.

• Tap until flattened with the front edge of the oil seal retainer.

3. Installation of the remaining components is in the reverse order of removal. Refer to

TM-208, "Removal and Installation (4WD)"

CAUTION:

• When replacing an engine or transmission you must make sure the dowels are installed cor-

rectly during re-assembly.

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of

drivetrain components.

WBIA0438E