Nissan Titan A60. Manual - part 401

EC-270

< DTC/CIRCUIT DIAGNOSIS >

[VK56DE]

P0441 EVAP CONTROL SYSTEM

TESTING CONDITION:

Always perform test at a temperature of 5

°C (41°F) or more.

WITH CONSULT-III

1. Start engine and warm it up to normal operating temperature.

2. Turn ignition switch OFF and wait at least 10 seconds.

3. Start engine and let it idle for at least 70 seconds.

4. Select “PURG FLOW P0441” of “EVAPORATIVE SYSTEM” in “DTC WORK SUPPORT” mode with CON-

SULT-III.

5. Touch “START”.

If “COMPLETED” is displayed, go to step 7.

6. When the following conditions are met, “TESTING” will be displayed on the CONSULT-III screen. Maintain

the conditions continuously until “TESTING” changes to “COMPLETED”. (It will take at least 35 seconds.)

If “TESTING” is not changed for a long time, retry from step 2.

7. Make sure that “OK” is displayed after touching “SELF-DIAG RESULTS”. If “NG” is displayed, refer to

Overall Function Check

INFOID:0000000006158700

Use this procedure to check the overall monitoring function of the EVAP control system purge flow monitoring.

During this check, a 1st trip DTC might not be confirmed.

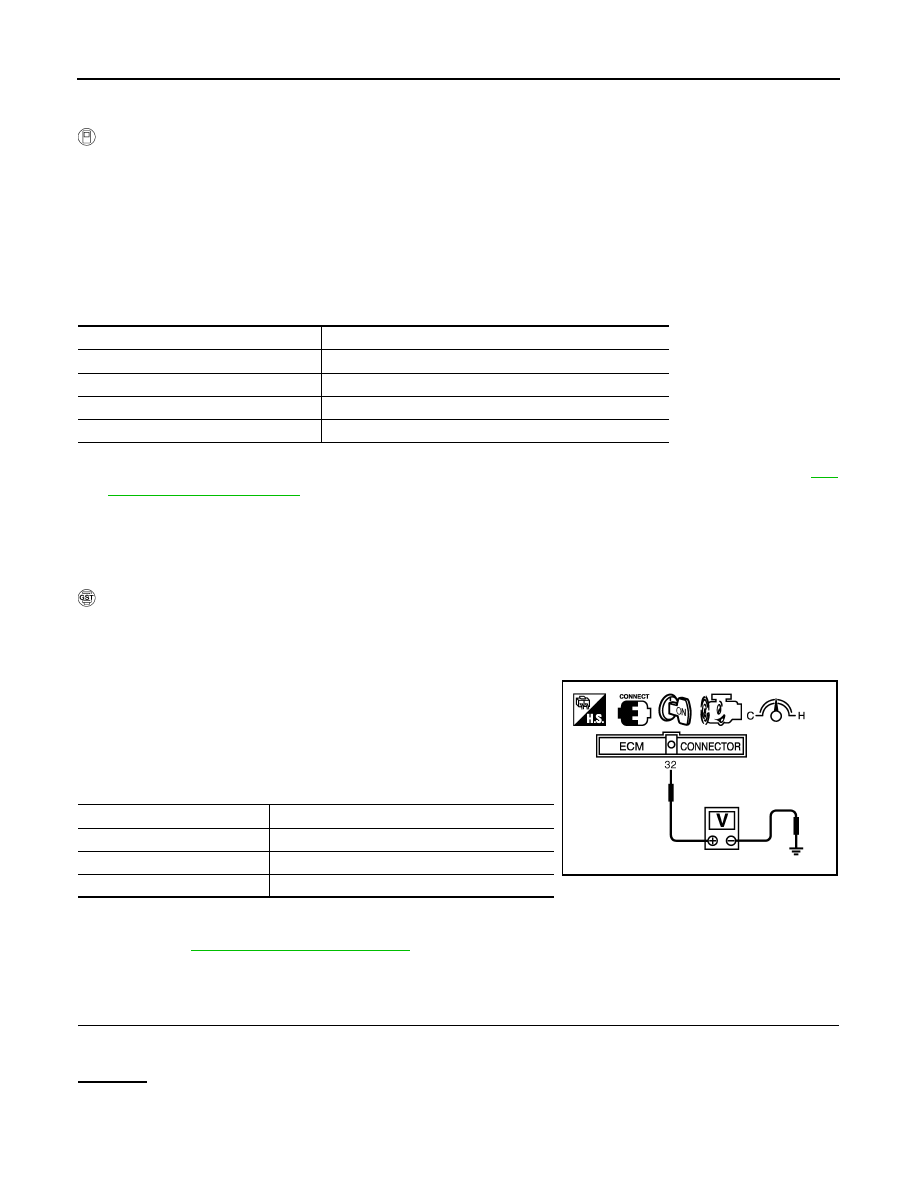

WITH GST

1. Lift up drive wheels.

2. Start engine (VDC switch OFF) and warm it up to normal operating temperature.

3. Turn ignition switch OFF, wait at least 10 seconds.

4. Start engine and wait at least 70 seconds.

5. Set voltmeter probes to ECM terminals 32 (EVAP control system

pressure sensor signal) and ground.

6. Check EVAP control system pressure sensor value at idle speed

and note it.

7. Establish and maintain the following conditions for at least 1

minute.

8. Verify that EVAP control system pressure sensor value stays 0.1V less than the value at idle speed (mea-

sured at step 6) for at least 1 second.

9. If NG, go to

Diagnosis Procedure

INFOID:0000000006158701

1.

CHECK EVAP CANISTER

1. Turn ignition switch OFF.

2. Check EVAP canister for cracks.

OK or NG

OK (With CONSULT-III)>>GO TO 2.

OK (Without CONSULT-III)>>GO TO 3.

NG

>> Replace EVAP canister.

Selector lever

Suitable position

VHCL SPEED SE

32 - 120 km/h (20 - 75 MPH)

ENG SPEED

500 - 3,000 rpm

B/FUEL SCHDL

1.0 - 12.0 msec

COOLAN TEMP/S

0 - 119

°C (32 - 246°F)

Air conditioner switch

ON

Headlamp switch

ON

Engine speed

Approx. 3,000 rpm

Gear position

Any position other than P, N or R

PBIB1109E