Nissan Quest E52. Manual - part 876

SERVICE DATA AND SPECIFICATIONS (SDS)

LU-17

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D

E

F

G

H

I

J

K

L

M

A

LU

N

P

O

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

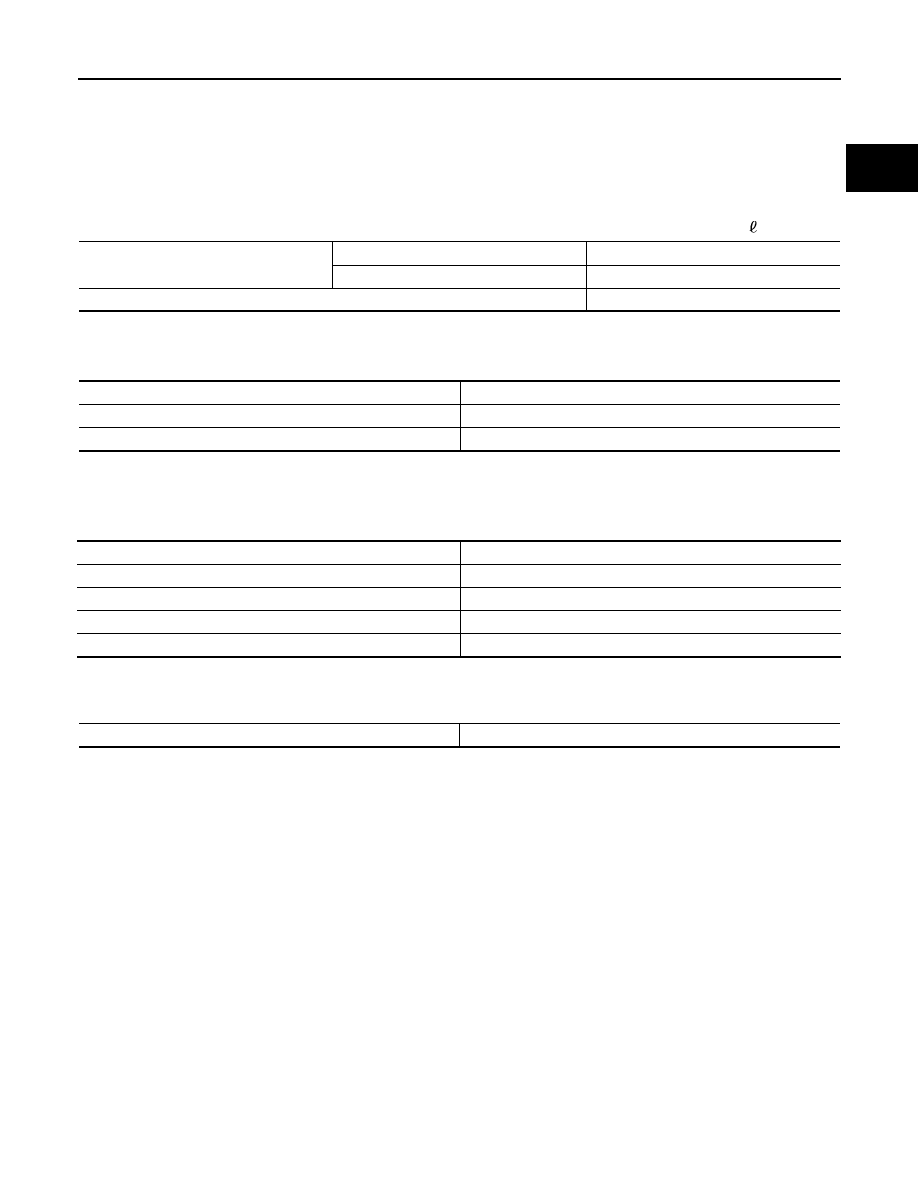

Periodical Maintenance Specification

INFOID:0000000009648853

ENGINE OIL CAPACITY (APPROXIMATE)

Unit:

(US qt, lmp qt)

Engine Oil Pressure

INFOID:0000000009648854

Unit: kPa (kg/cm

2

, psi)

*: Engine oil temperature at 80

°

C (176

°

F)

Oil Pump

INFOID:0000000009648855

Unit: mm (in)

Regulator Valve

INFOID:0000000009648856

Unit: mm (in)

Drain and refill

With oil filter change

4.6 (4-7/8, 4)

Without oil filter change

4.3 (4-1/2, 3-3/4)

Dry engine (Overhaul)

5.3 (5-5/8, 4-5/8)

Engine speed

Approximate discharge pressure*

Idle speed

More than 98 (1.0, 14)

2,000 rpm

More than 294 (3.0, 43)

Clearance between oil pump outer rotor and oil pump body

0.114 - 0.260 (0.0045 - 0.0102)

Tip clearance between oil pump inner rotor and oil pump outer rotor

Below 0.180 (0.0071)

Side clearance between oil pump inner rotor and oil pump body

0.030 - 0.070 (0.0012 - 0.0028)

Side clearance between oil pump outer rotor and oil pump body

0.050 - 0.110 (0.0020 - 0.0043)

Oil pump inner rotor to oil pump body clearance

0.045 - 0.091 (0.0018 - 0.0036)

Regulator valve to oil pump body clearance

0.040 - 0.097 (0.0016 - 0.0038)