Nissan Quest E52. Manual - part 875

OIL COOLER

LU-13

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

M

A

LU

N

P

O

1.

Remove front wheel (RH).

2.

Remove splash guard (RH). Refer to

3.

Drain engine coolant from radiator and cylinder block. Refer to

and

NOTE:

Perform this step when removing water pipes.

4.

Remove oil filter. Refer to

LU-11, "Removal and Installation"

CAUTION:

Never spill engine oil on drive belt.

5.

Disconnect water hoses from oil cooler.

• When removing oil cooler only, pinching water hoses near oil cooler to prevent engine coolant from spill-

ing out.

• Remaining engine coolant in piping will come out. Use a tray to collect it.

CAUTION:

• Perform this step when the engine is cold.

• Never spill engine coolant on drive belt.

6.

Remove connector bolt, and remove oil cooler.

CAUTION:

Never spill engine oil to rubber parts such as drive belt.

7.

Remove water hoses if necessary.

INSTALLATION

CAUTION:

Do not reuse O-rings.

Note the following, and install in the reverse order of removal.

• Check that no foreign objects are adhering to the installation surfaces of oil cooler and oil pan (upper).

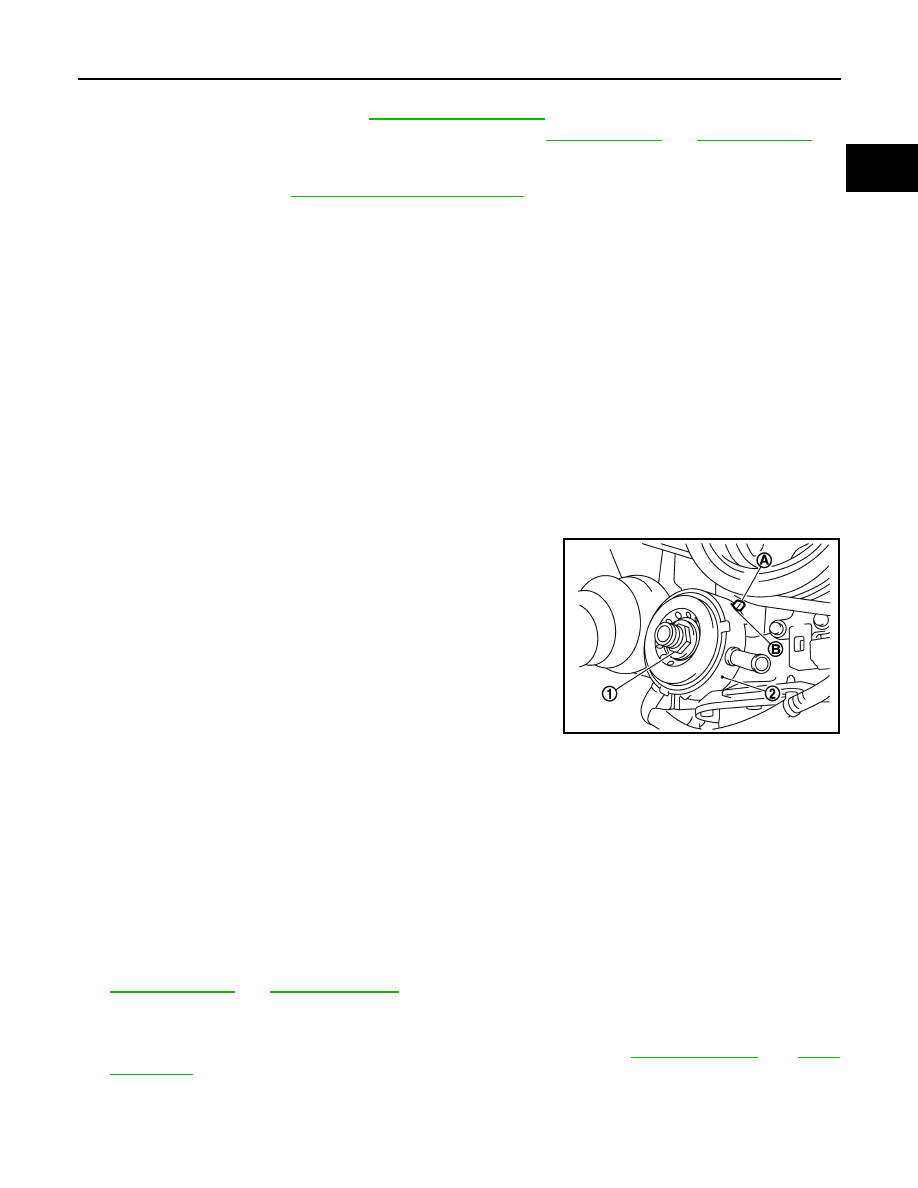

• Align cutout (B) on oil cooler (2) with protrusion (A) on oil pan

(upper) side, and tighten connector bolt (1).

Inspection

INFOID:0000000009648848

INSPECTION AFTER REMOVAL

Oil Cooler

Check oil cooler for cracks. Check oil cooler for clogging by blowing through engine coolant inlet. If necessary,

replace oil cooler.

Relief Valve

Inspect relief valve for movement, cracks and breaks by pushing the ball. If replacement is necessary, remove

relief valve by prying it out with a suitable tool. Install a new relief valve in place by tapping it.

INSPECTION AFTER INSTALLATION

1.

Check the engine oil level and the engine coolant level and add engine oil and engine coolant. Refer to

.

2.

Start the engine, and check there is no leakage of engine oil or engine coolant.

3.

Stop the engine and wait for 10 minutes.

4.

Check the engine oil level and the engine coolant level again. Refer to

and

JPBIA1680ZZ