Nissan Quest E52. Manual - part 713

CONDENSER

HA-43

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

CONDENSER

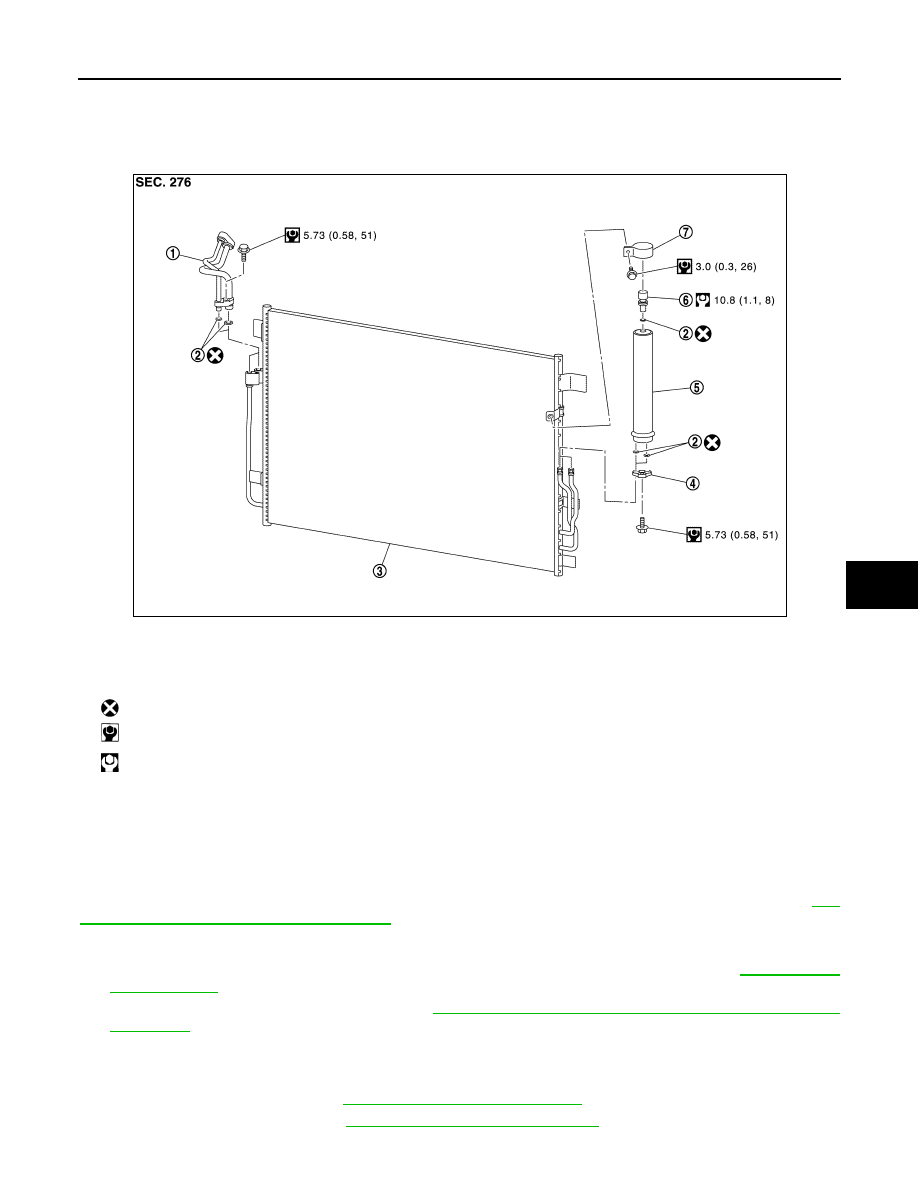

Exploded View

INFOID:0000000009651587

CONDENSER

CONDENSER : Removal and Installation

INFOID:0000000009651588

CAUTION:

Perform lubricant return operation before each refrigeration system disassembly. However, if a large

amount of refrigerant or lubricant is detected, never perform lubricant return operation. Refer to

22, "Perform Lubricant Return Operation"

REMOVAL

1.

Use a refrigerant collecting equipment (for HFC-134a) to discharge the refrigerant. Refer to

2.

Remove condenser pipe assembly. Refer to

HA-44, "CONDENSER PIPE ASSEMBLY : Removal and

.

CAUTION:

Cap or wrap the joint of the condenser pipe assembly and condenser with suitable material such

as vinyl tape to avoid the entry of air.

3.

Remove horn assembly. Refer to

HRN-6, "Removal and Installation"

.

4.

Remove air guide upper. Refer to

DLK-428, "Removal and Installation"

.

1.

Condenser pipe assembly

2.

O-ring

3.

Condenser

4.

Bracket

5.

Liquid tank

6.

Refrigerant pressure sensor

7.

Liquid tank bracket

: Always replace after every disassembly.

: N·m (kg-m, in-lb)

: N·m (kg-m, ft-lb)

JMIIA1839GB