Nissan Quest E52. Manual - part 671

FAX-12

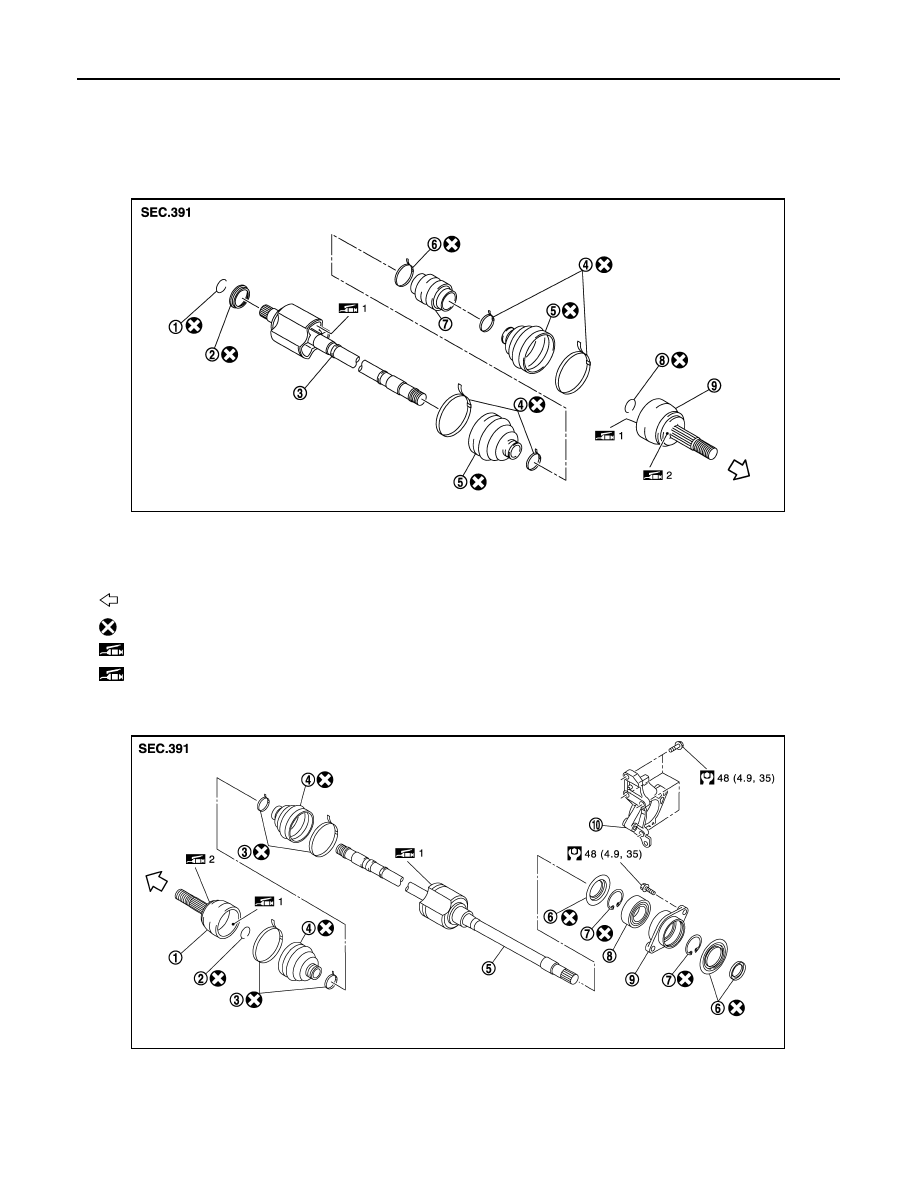

< REMOVAL AND INSTALLATION >

FRONT DRIVE SHAFT BOOT

FRONT DRIVE SHAFT BOOT

Exploded View

INFOID:0000000009651667

LEFT SIDE

RIGHT SIDE

1.

Circular clip

2.

Dust shield

3.

Housing assembly

4.

Boot band

5.

Boot

6.

Damper band

7.

Dynamic damper

8.

Circular clip

9.

Joint sub-assembly

: Wheel side

: Always replace after every disassembly.

1: Fill NISSAN Genuine grease or equivalent.

2: Apply paste [service parts (440037S000)].

JPDIF0242ZZ

1.

Joint sub-assembly

2.

Circular clip

3.

Boot band

4.

Boot

5.

Housing assembly

6.

Dust shield

7.

Snap ring

8.

Support bearing

9.

Bearing housing

10. Support bearing bracket

JSDIA2706GB