Nissan Quest E52. Manual - part 587

CYLINDER HEAD

EM-97

< UNIT DISASSEMBLY AND ASSEMBLY >

[VQ35DE]

C

D

E

F

G

H

I

J

K

L

M

A

EM

N

P

O

Disassembly and Assembly

INFOID:0000000009652796

DISASSEMBLY

1.

Remove spark plug with spark plug wrench (commercial service tool).

2.

Remove valve lifter.

• Identify installation positions, and store them without mixing them up.

3.

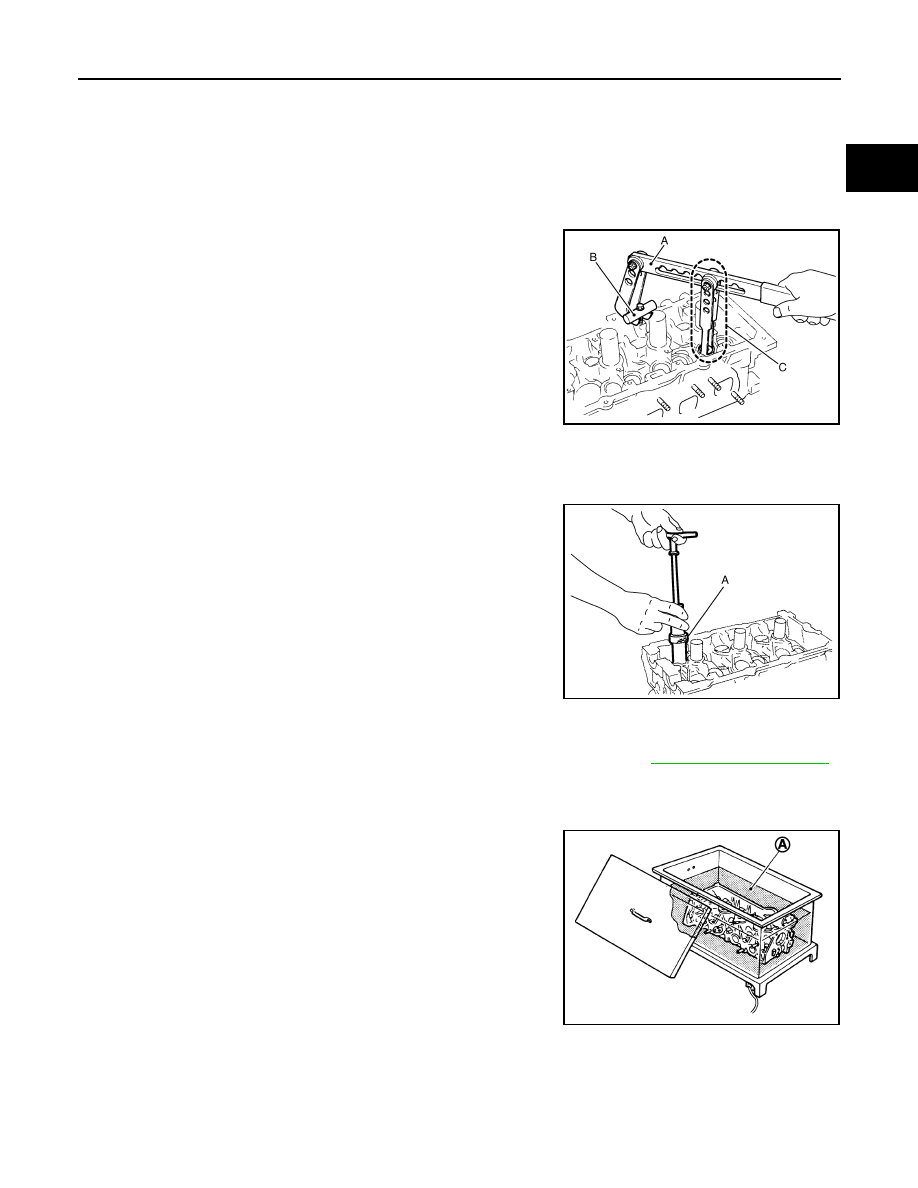

Remove valve collet.

• Compress valve spring with the valve spring compressor [SST:

KV10116200 (J-26336-A)] (A), the attachment [SST:

KV10115900 (J-26336-20)] (C) and the adapter [SST:

KV10109220 ( — )] (B). Remove valve collet with a magnet

hand.

CAUTION:

When working, take care not to damage valve lifter holes.

4.

Remove valve spring retainer, valve spring and valve spring seat.

5.

Push valve stem to combustion chamber side, and remove valve.

• Identify installation positions, and store them without mixing them up.

6.

Remove valve oil seal with the valve oil seal puller [SST:

KV10107902 (J-38959)] (A).

7.

Remove valve seat, if valve seat must be replaced.

• Bore out old seat until it collapses. Boring should not continue beyond the bottom face of the seat

recess in cylinder head. Set the machine depth stop to ensure this. Refer to

CAUTION:

Prevent to scratch cylinder head by excessive boring.

8.

Remove valve guide, if valve guide must be replaced.

a.

To remove valve guide, heat cylinder head to 110 to 130

°

C (230

to 266

°

F) by soaking in heated oil (A).

JPBIA0180ZZ

JPBIA0177ZZ

JPBIA0184ZZ