Nissan Quest E52. Manual - part 539

EC-366

< DTC/CIRCUIT DIAGNOSIS >

[VQ35DE]

P1572 ASCD BRAKE SWITCH

5.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> GO TO 4.

4.

PERFORM DTC CONFIRMATION PROCEDURE A-II

1.

Drive the vehicle for at least 5 consecutive seconds under the following conditions.

CAUTION:

Always drive vehicle at a safe speed.

NOTE:

This procedure may be conducted with the drive wheels lifted in the shop or by driving the vehicle.

If a road test is expected to be easier, it is unnecessary to lift the vehicle.

2.

Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

5.

PERFORM COMPONENT FUNCTION CHECK

Perform component function check. Refer to

EC-366, "Component Function Check"

NOTE:

Use component function check to check the overall function of ASCD brake switch. During this check, a DTC

might not be confirmed.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Go to

Component Function Check

INFOID:0000000009651215

1.

PERFORM COMPONENT FUNCTION CHECK

1.

Turn ignition switch ON.

2.

Check the voltage between ECM harness connectors.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> GO TO 2.

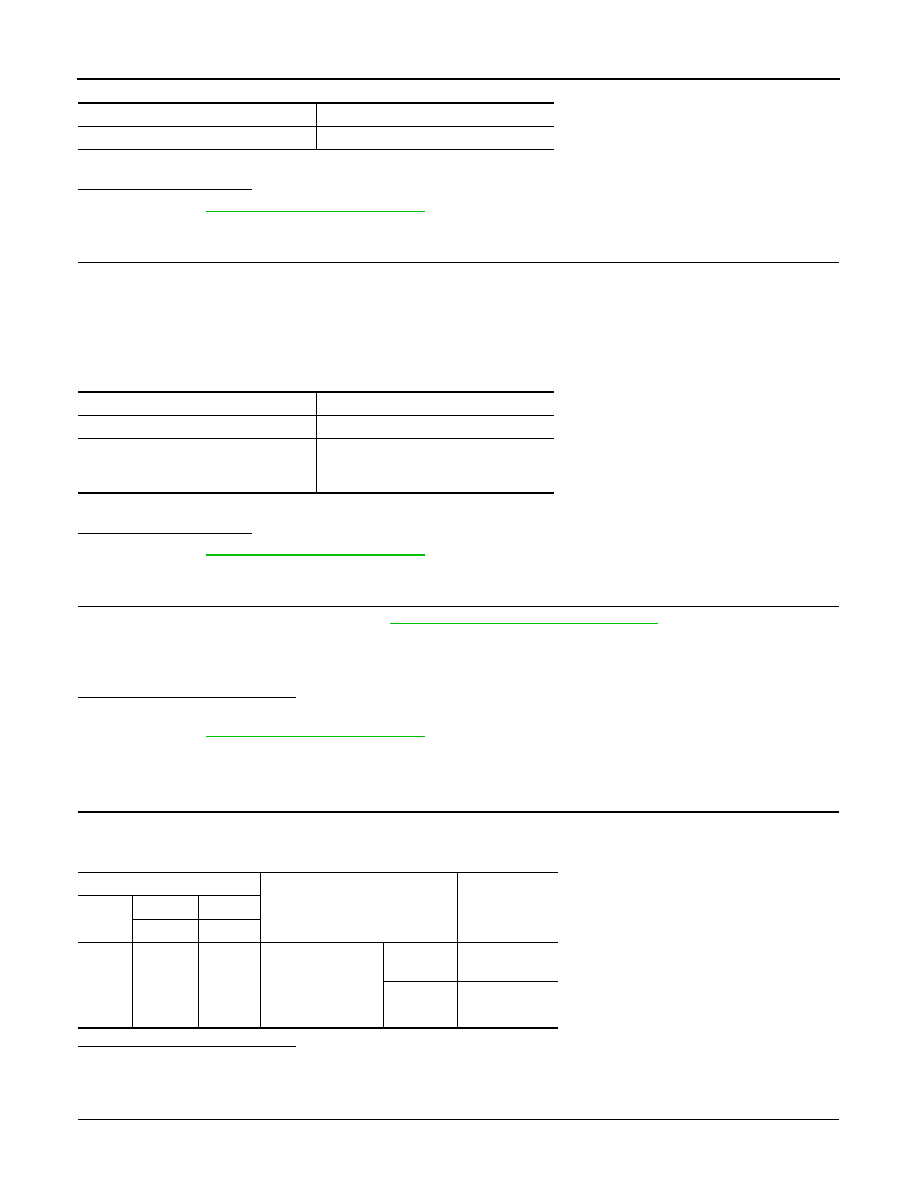

2.

PERFORM COMPONENT FUNCTION CHECK-II

Check the voltage between ECM harness connectors.

VHCL SPEED SE

More than 30 km/h (19 mph)

Selector lever

Suitable position

VHCL SPEED SE

More than 30 km/h (19 mph)

Selector lever

Suitable position

Driving location

Depress the brake pedal for more than

five seconds so as not to come off from

the above-mentioned vehicle speed.

ECM

Condition

Voltage

Con-

nector

+

–

Terminal

Terminal

E16

126

(ASCD

brake

switch

signal)

128

Brake pedal

Slightly

depressed

Approx. 0 V

Fully re-

leased

Battery voltage