Nissan Quest E52. Manual - part 285

CO-10

< PERIODIC MAINTENANCE >

ENGINE COOLANT

6.

Install air duct assembly and air cleaner cases (upper and lower) assembly. Refer to

.

7.

Install radiator cap.

8.

Start the engine.

9.

Maintain the engine at 1,800 rpm for approximately 10 seconds. After performing this, stop the engine.

10. Remove radiator cap with the engine cold (approx. 50

°

C or less), and check the cooling water level. If the

fluid level is low, refill with cooling water to the lip of radiator.

11. Repeat Steps from 7 to 9 four times.

12. Cap the radiator, and start the engine.

13. Warm up engine until opening thermostat. Standard for warming-up time is approximately 10 minutes at

3,000 rpm.

• Check thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat engine.

14. Stop the engine and cool down to less than approximately 50

°

C (122

°

F).

• Cool down using fan to reduce the time.

• If necessary, refill radiator up to filler neck with engine coolant.

CAUTION:

Never adhere the engine coolant to electronic equipments. (alternator etc.)

15. Refill reservoir tank to “MAX” level line with engine coolant.

16. Repeat steps 7 through 10 two or more times with radiator cap installed until engine coolant level no

longer drops.

17. Check cooling system for leakage with engine running.

18. Warm up the engine, and check for sound of engine coolant flow while running engine from idle up to

3,000 rpm with heater temperature controller set at several position between “COOL” and “WARM”.

• Sound may be noticeable at heater unit.

19. Repeat step 13 three times.

20. If sound is heard, bleed air from cooling system by repeating step 5, and steps from 7 to 14 until engine

coolant level no longer drops.

Flushing

INFOID:0000000009650541

1.

Install reservoir tank if removed and radiator drain plug.

CAUTION:

Be sure to clean drain plug and install with new O-ring.

If water drain plugs on cylinder block are removed, close and tighten them. Refer to

2.

Remove air duct assembly and air cleaner cases (upper and lower) assembly. Refer to

.

3.

Remove air bleeder plug.

4.

Fill with cooling water until it overflows from the bleeder plug.

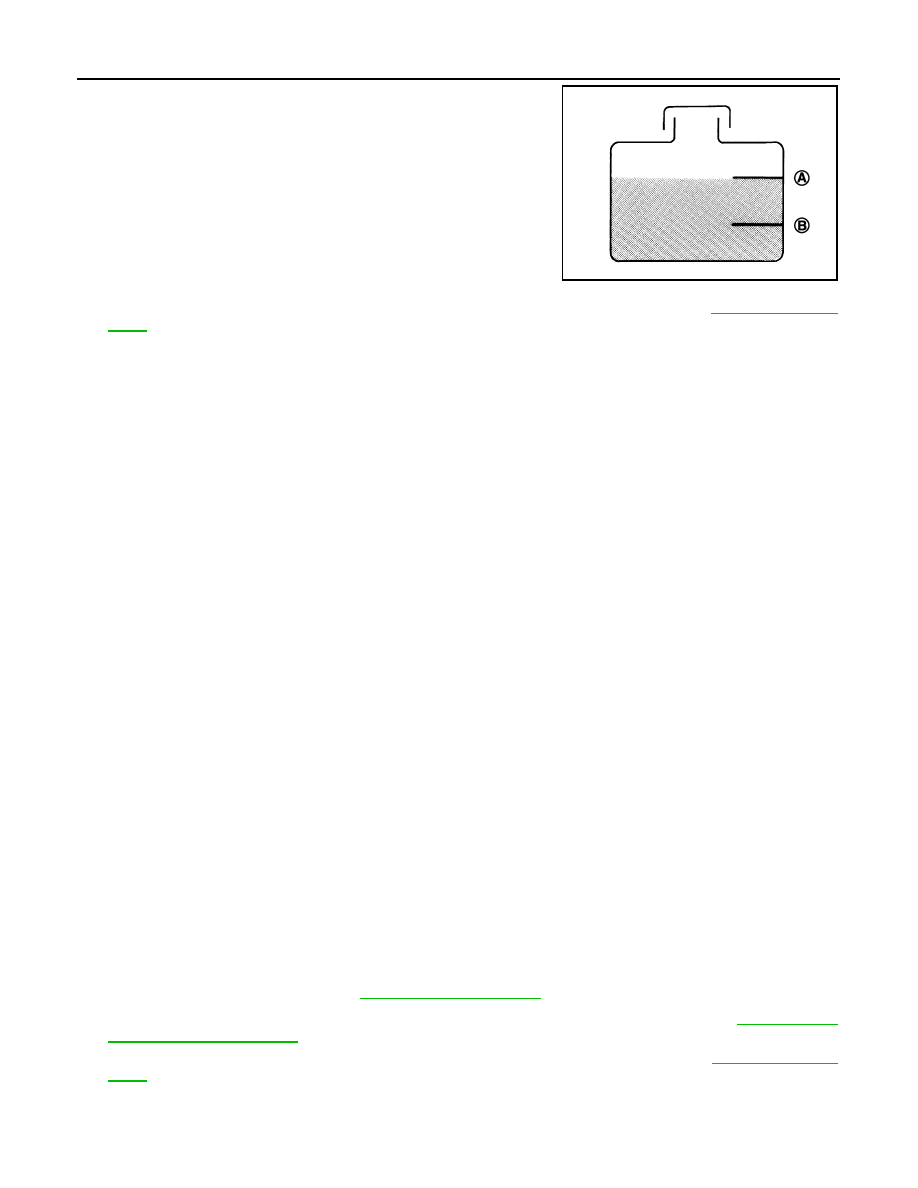

A

: MAX

B

: MIN

JPBIA0102ZZ

Tightening torque

: Refer to