Nissan Cube. Manual - part 938

TM-8

< DTC/CIRCUIT DIAGNOSIS >

[6MT: RS6F94R]

POSITION SWITCH

DTC/CIRCUIT DIAGNOSIS

POSITION SWITCH

BACK-UP LAMP SWITCH

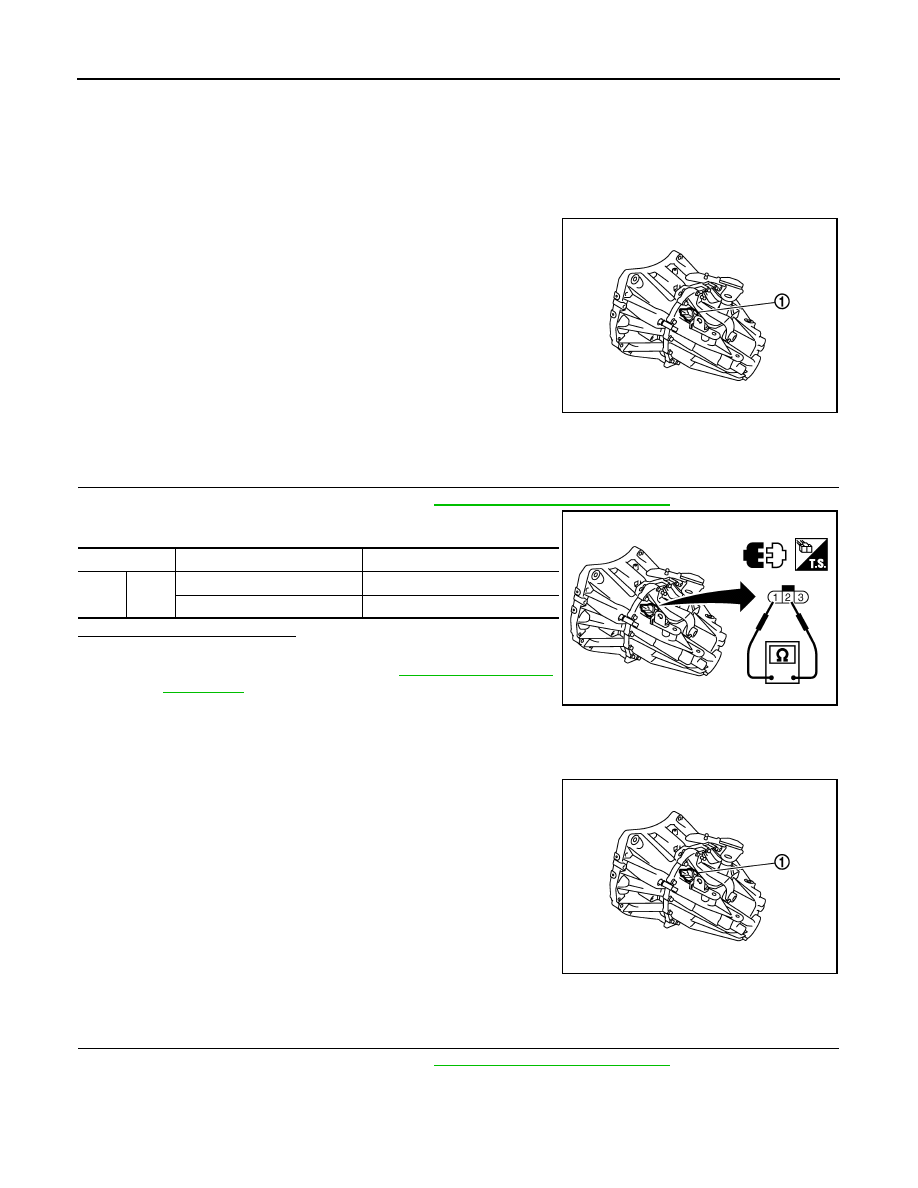

BACK-UP LAMP SWITCH : Component Parts Location

INFOID:0000000009948857

BACK-UP LAMP SWITCH : Component Inspection

INFOID:0000000009948858

1.

CHECK BACK-UP LAMP SWITCH

1.

Disconnect position switch connector. Refer to

TM-23, "Removal and Installation"

.

2.

Check continuity between position switch terminals.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace position switch. Refer to

PARK/NEUTRAL POSITION (PNP) SWITCH

PARK/NEUTRAL POSITION (PNP) SWITCH : Component Parts Location

INFOID:0000000009948859

PARK/NEUTRAL POSITION (PNP) SWITCH : Component Inspection

INFOID:0000000009948860

1.

CHECK PARK/NEUTRAL POSITION (PNP) SWITCH

1.

Disconnect position switch connector. Refer to

TM-23, "Removal and Installation"

.

1

: Position switch

JPDIC0070ZZ

Terminals

Condition

Continuity

1

2

Reverse gear position

Existed

Except reverse gear position

Not existed

PCIB1781E

1

: Position switch

JPDIC0070ZZ