Nissan Cube. Manual - part 661

MA-18

< PERIODIC MAINTENANCE >

ENGINE MAINTENANCE

3.

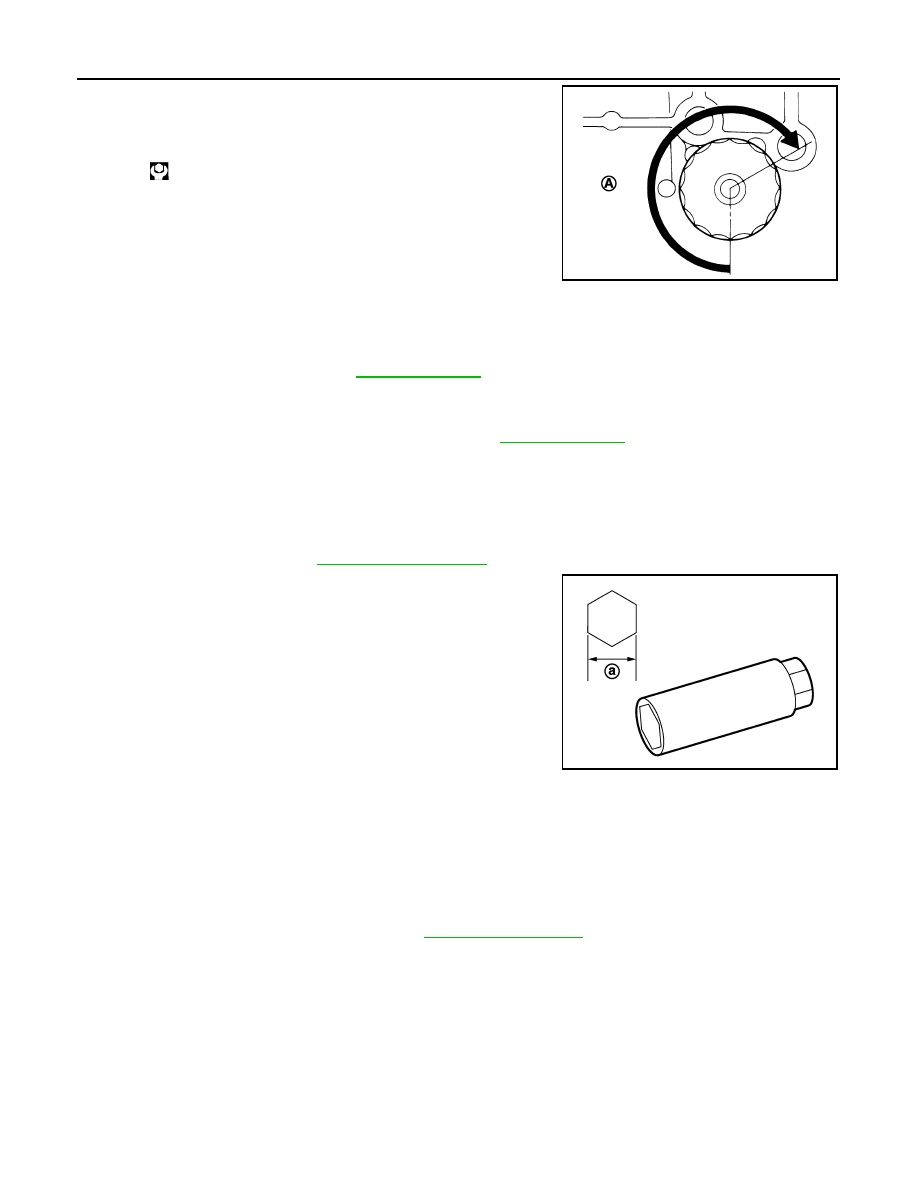

Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn (A). Or tighten to specification.

OIL FILTER : Inspection

INFOID:0000000009949429

INSPECTION AFTER INSTALLATION

1.

Check the engine oil level. Refer to

.

2.

Start the engine, and check that there is no leakage of engine oil.

3.

Stop the engine and wait for 10 minutes.

4.

Check the engine oil level, and adjust the level. Refer to

.

SPARK PLUG

SPARK PLUG : Removal and Installation

INFOID:0000000010269295

REMOVAL

1.

Remove ignition coil. Refer to

.

2.

Remove spark plug with a spark plug wrench (commercial ser-

vice tool).

CAUTION:

Never drop or shock spark plug.

INSTALLATION

Install in the reverse order of removal.

SPARK PLUG : Inspection

INFOID:0000000010269296

INSPECTION AFTER REMOVAL

Use the standard type spark plug for normal condition.

CAUTION:

Oil filter:

: 17.7 N·m (1.8 kg-m, 13 ft-lb)

JPBIA0077ZZ

a

: 14 mm (0.55 in)

JPBIA0030ZZ

Spark plug (Standard type)

: Refer to