Nissan Cube. Manual - part 569

HAC-114

< SYMPTOM DIAGNOSIS >

[AUTOMATIC AIR CONDITIONING]

AUTOMATIC AIR CONDITIONING SYSTEM

SYMPTOM DIAGNOSIS

AUTOMATIC AIR CONDITIONING SYSTEM

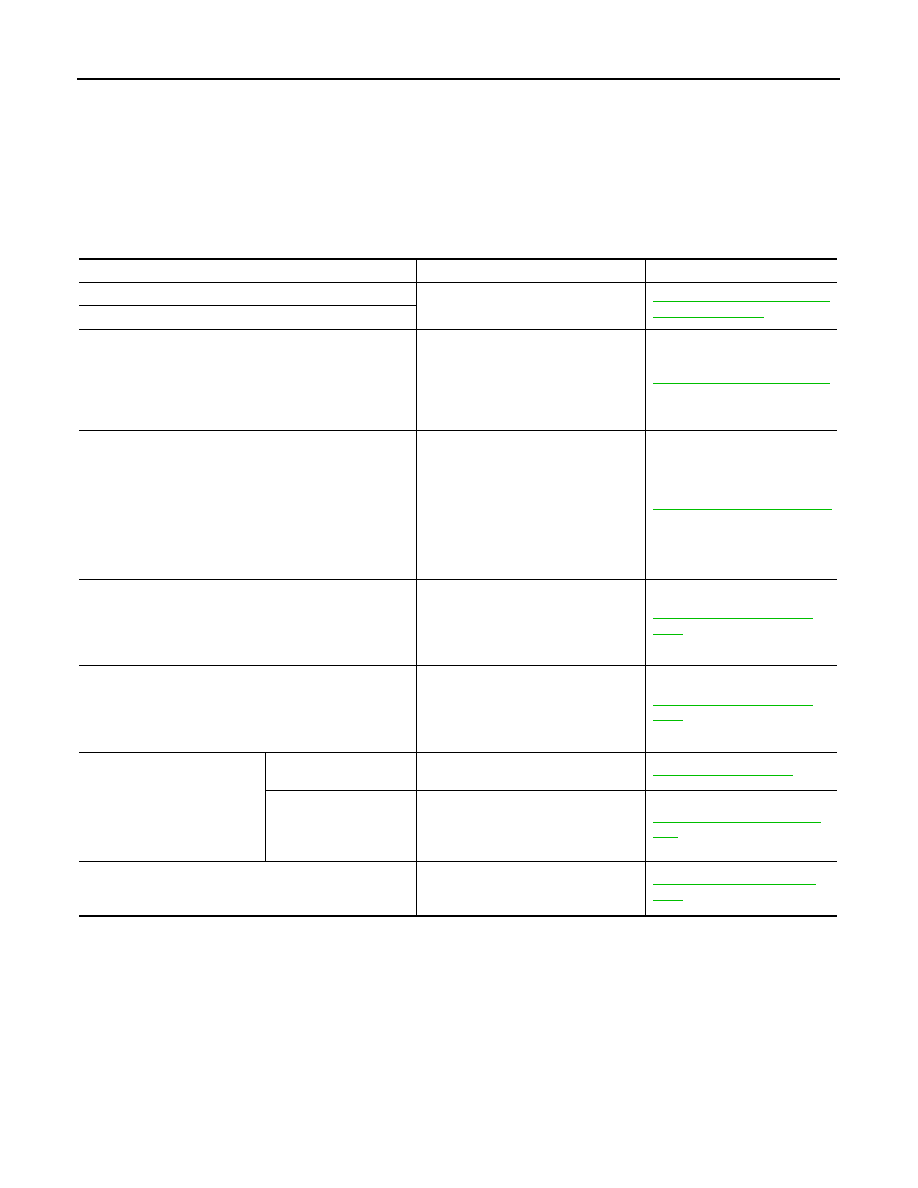

Diagnosis Chart By Symptom

INFOID:0000000009951023

CAUTION:

Perform the self-diagnoses with on board diagnosis and CONSULT before performing the symptom

diagnosis. If any malfunction result or DTC is detected, perform the corresponding diagnosis.

Symptom

Corresponding malfunction part

Check item/Reference

A/C system does not activate.

• Power supply circuit of A/C system

• A/C control (built-in A/C auto amp.)

HAC-64, "A/C AUTO AMP. : Di-

agnosis Procedure"

A/C system cannot be controlled.

Blower motor operation is malfunctioning.

• Blower motor

• Power supply system of blower mo-

tor

• The circuit between blower motor

and A/C auto amp.

• A/C auto amp.

Magnet clutch does not operate.

• Magnet clutch

• The circuit between magnet clutch

and IPDM E/R

• IPDM E/R (A/C relay)

• The circuit between ECM and refrig-

erant pressure sensor

• Refrigerant pressure sensor

• CAN communication line

• A/C auto amp.

• Insufficient cooling

• No cool air comes out. (Air flow volume is normal.)

• Magnet clutch control system

• Drive belt slipping

• Cooler cycle

• Air leakage from each duct

• Temperature setting trimmer

HAC-115, "Diagnosis Proce-

dure"

• Insufficient heating

• No warm air comes out. (Air flow volume is normal.)

• Engine cooling system

• Heater hose

• Heater core

• Air leakage from each duct

• Temperature setting trimmer

HAC-117, "Diagnosis Proce-

dure"

Noise is heard when the A/C

system operates.

During compressor op-

eration

Cooler cycle

During blower motor op-

eration

• Mixing any foreign object in blower

motor

• Blower motor fan breakage

• Blower motor rotation inferiority

HAC-57, "Component Inspec-

tion"

• Memory function dose not operates.

• Setting temperature dose not memorize.

• Power supply system of A/C auto

amp.

• A/C auto amp.