Nissan Cube. Manual - part 535

PERFORMANCE TEST

HA-29

< PERIODIC MAINTENANCE >

C

D

E

F

G

H

J

K

L

M

A

B

HA

N

O

P

PERFORMANCE TEST

Inspection

INFOID:0000000009950347

INSPECTION PROCEDURE

1.

Connect recovery/recycling/recharging equipment (for HFC-134a) or manifold gauge.

2.

Start the engine, and set to the following condition.

Test condition

3.

Maintain test condition until A/C system becomes stable. (Approximately 10 minutes)

4.

Check that test results of “recirculating-to-discharge air temperature” and “ambient air temperature-to-

operating pressure” are within the specified value.

5.

When test results are within the specified value, inspection is complete.

If any of test result is out of the specified value, perform diagnosis by gauge pressure. Refer to

.

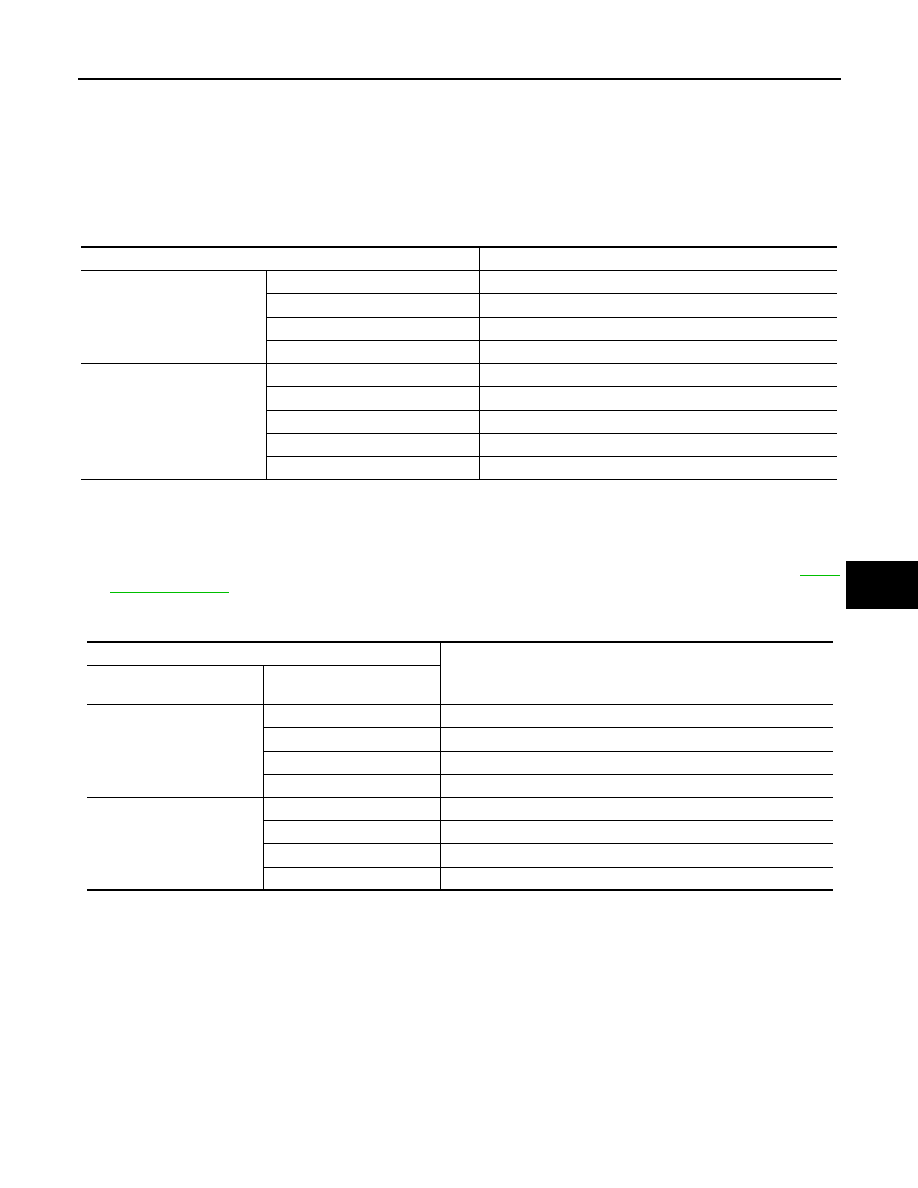

RECIRCULATING-TO-DISCHARGE AIR TEMPERATURE TABLE

AMBIENT AIR TEMPERATURE-TO-OPERATING PRESSURE TABLE

Surrounding condition

Indoors or in the shade (in a well-ventilated place)

Vehicle condition

Door

Closed

Door glass

Full open

Hood

Open

Engine speed

Idle speed

A/C condition

Temperature control switch or dial

Full cold

A/C switch

ON

Air outlet

VENT (ventilation)

Intake door position

Recirculation

Fan speed

Maximum speed set

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature from center ventilator

°

C (

°

F)

Relative humidity

%

Air temperature

°

C (

°

F)

50 – 60

20 (68)

10.2 – 12.1 (50 – 54)

25 (77)

13.2 – 15.3 (56 – 60)

30 (86)

17.7 – 20.1 (64 – 68)

35 (95)

22.2 – 25.8 (72 – 78)

60 – 70

20 (68)

12.1 – 13.9 (54 – 57)

25 (77)

15.3 – 17.5 (60 – 64)

30 (86)

20.1 – 23.0 (68 – 73)

35 (95)

25.8 – 29.2 (78 – 85)