Nissan Cube. Manual - part 423

EM-96

< UNIT DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

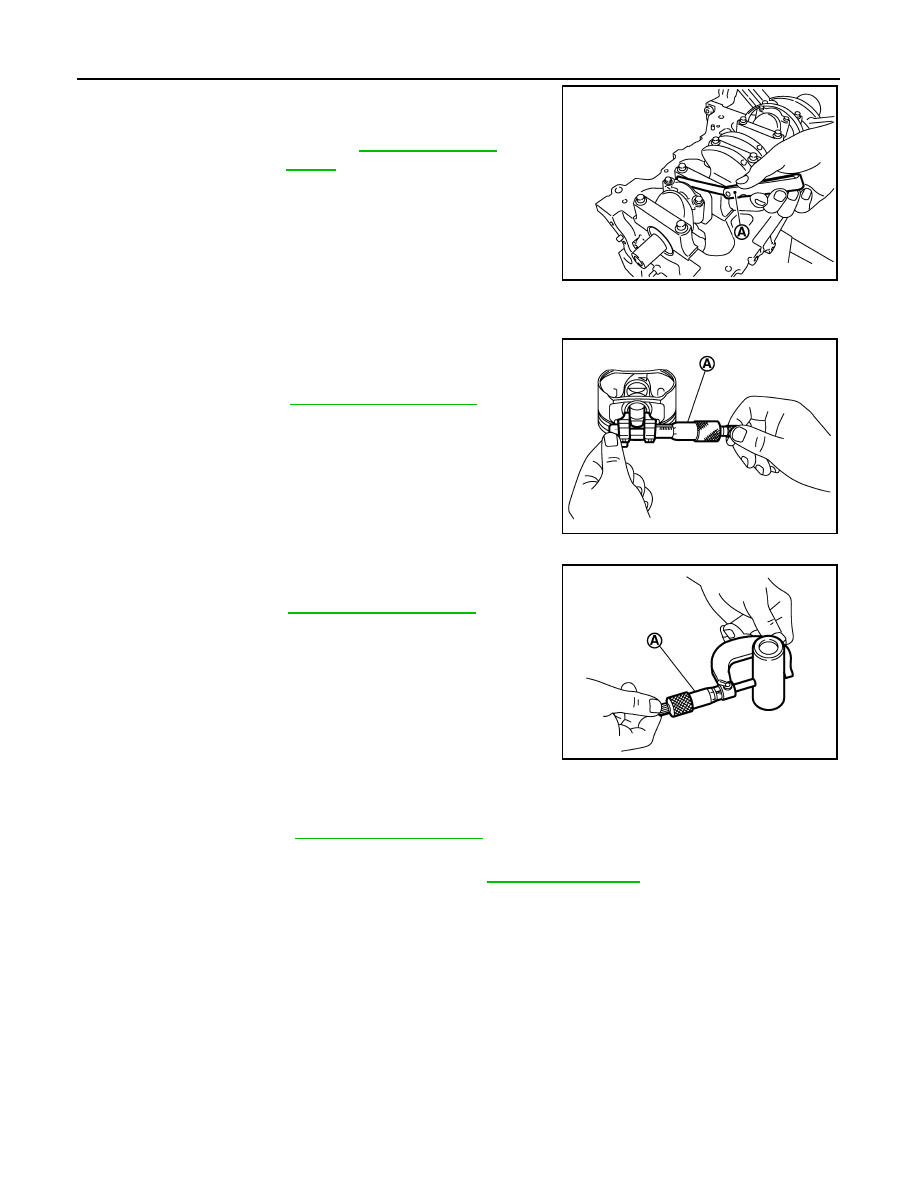

• Measure the side clearance between connecting rod and crank-

shaft arm with a feeler gauge (A).

• If the measured value exceeds the limit, replace connecting rod,

and measure again. If it still exceeds the limit, replace crankshaft

also.

PISTON TO PISTON PIN OIL CLEARANCE

Piston Pin Hole Diameter

Measure the inner diameter of piston pin hole with an inside

micrometer (A).

Piston Pin Outer Diameter

Measure the outer diameter of piston pin with a micrometer (A).

Piston to Piston Pin Oil Clearance

(Piston to piston pin oil clearance) = (Piston pin hole diameter) – (Piston pin outer diameter)

• If oil clearance is out of the standard, replace piston and piston pin assembly.

• When replacing piston and piston pin assembly. Refer to

.

NOTE:

• Piston is available together with piston pin as assembly.

• Piston pin (piston pin hole) grade is provided only for the parts installed at the plant. For service parts, no

grades can be selected. (Only grade “0” is available.)

PISTON RING SIDE CLEARANCE

Standard and Limit

: Refer to

.

PBIC3251J

Standard

: Refer to

.

PBIC3265J

Standard :

Refer

.

PBIC3266J

Standard :