Nissan Cube. Manual - part 422

EM-92

< UNIT DISASSEMBLY AND ASSEMBLY >

CYLINDER BLOCK

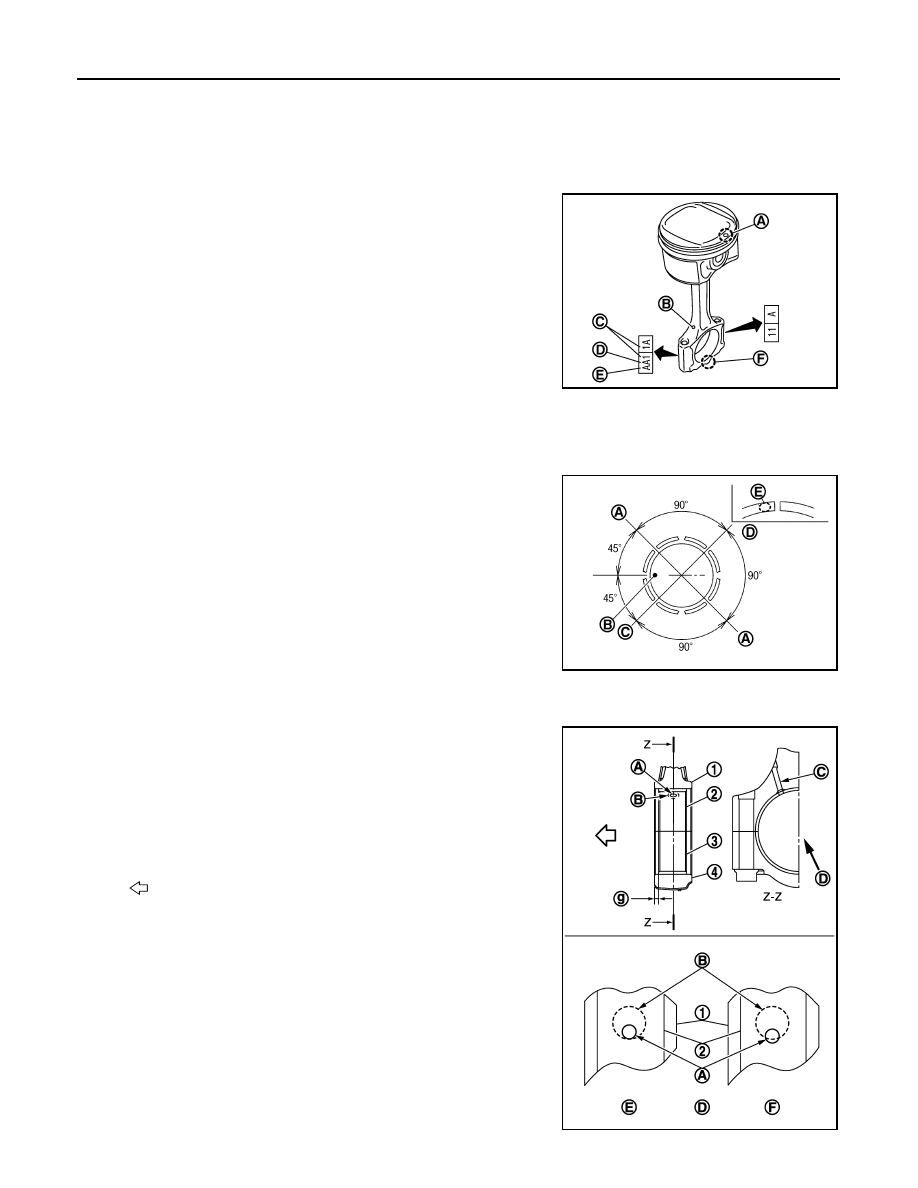

a.

Using snap ring pliers, install new snap ring to the groove of the piston rear side.

• Insert it fully into groove to install.

b.

Assemble piston to connecting rod.

• Using an industrial use drier or similar tool, heat the piston until the piston pin can be pushed in by hand

without excess force [approximately 60 to 70

°

C (140 to 158

°

F)]. From the front to the rear, insert piston

pin into piston and connecting rod.

• Assemble so that the front mark (A) on the piston head and

the oil hole (B) and the cylinder number (C) on connecting rod

are positioned as shown in the figure.

c.

Install new snap ring to the groove of the piston front side.

• Insert it fully into groove to install.

• After installing, check that connecting rod moves smoothly.

8.

Using a piston ring expander (commercial service tool), install

piston rings.

CAUTION:

• Be careful not to damage piston.

• Be careful not to damage piston rings by expanding them excessively.

• Position each ring with the gap as shown in the figure referring

to the piston front mark.

CAUTION:

Never contact the rail end gap under the oil ring with the

oil drain cast groove of piston.

• Install second ring with the stamped surface facing upward.

9.

Install connecting rod bearing upper (2) and lower (3) to con-

necting rod (1) and connecting rod cap (4).

• Install the connecting rod in the dimension shown in the figure.

• Check that connecting rod bearing oil hole (A) is completely in

the inside of connecting rod oil hole chamfered area (B).

• When installing connecting rod bearings, apply new engine oil

to the bearing surface (inside). Do not apply new engine oil to

the back surface, but thoroughly clean it.

NOTE:

• There is no positioning tab.

• Install the connecting rod bearings in the center of connect-

ing rod and connecting rod cap as shown in the figure. For

service operation, the center position can be checked, visu-

ally.

D

: Big end diameter grade

E

: Small end diameter grade

F

: Front mark (connecting rod)

A

: Oil ring upper or lower rail gap

B

: Front mark

C

: Second ring and oil ring spacer gap

D

: Top ring gap

E

: Stamped mark

PBIC3241J

PBIC3242J

C

: Oil hole (connecting rod)

D

: View D

E

: OK

F

: NG

g

: 2.55 - 2.95 mm (0.1004 - 0.1161 in)

: Engine front

JPBIA2155ZZ