Nissan Cube. Manual - part 314

EC-142

< DTC/CIRCUIT DIAGNOSIS >

[MR18DE]

P0037, P0038 HO2S2 HEATER

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000009947258

1.

CHECK GROUND CONNECTION

1.

Turn ignition switch OFF.

2.

Check ground connection E38. Refer to

Is the inspection result normal?

YES

>> GO TO 2.

NO

>> Repair or replace ground connection.

2.

CHECK HO2S2 POWER SUPPLY CIRCUIT

1.

Disconnect heated oxygen sensor 2 (HO2S2) harness connector.

2.

Turn ignition switch ON.

3.

Check the voltage between HO2S2 harness connector and ground.

Is the inspection result normal?

YES

>> GO TO 4.

NO

>> GO TO 3.

3.

DETECT MALFUNCTIONING PART

Check the following.

• Harness connectors E8, F1

• IPDM E/R connector E15

• 15 A fuse (No. 61)

• Harness for open or short between heated oxygen sensor 2 and fuse

>> Repair open circuit or short to ground or short to power in harness or connectors.

4.

CHECK HO2S2 OUTPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1.

Turn ignition switch OFF.

2.

Disconnect ECM harness connector.

3.

Check the continuity between HO2S2 harness connector and ECM harness connector.

4.

Also check harness for short to ground and short to power.

Is the inspection result normal?

YES

>> GO TO 5.

NO

>> Repair open circuit or short to ground or short to power in harness or connectors.

5.

CHECK HEATED OXYGEN SENSOR 2 HEATER

EC-143, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> GO TO 6.

6.

REPLACE HEATED OXYGEN SENSOR 2

Replace heated oxygen sensor 2. Refer to

.

CAUTION:

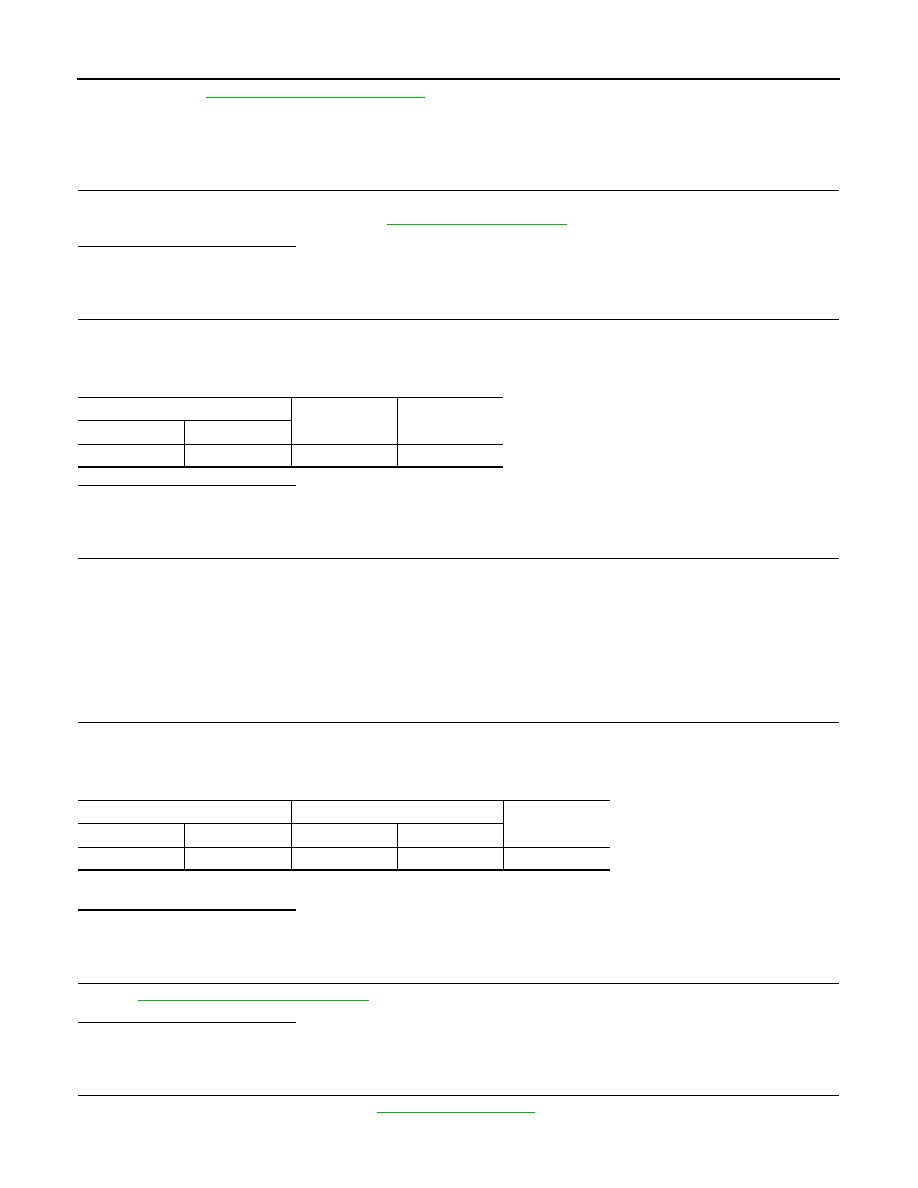

HO2S2

Ground

Voltage

Connector

Terminal

F30

2

Ground

Battery voltage

HO2S2

ECM

Continuity

Connector

Terminal

Connector

Terminal

F30

3

F7

5

Existed