Nissan Versa Note. Manual - part 868

WHEEL

WT-41

< PERIODIC MAINTENANCE >

C

D

F

G

H

I

J

K

L

M

A

B

WT

N

O

P

PERIODIC MAINTENANCE

WHEEL

Inspection

INFOID:0000000009446796

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel

runout.

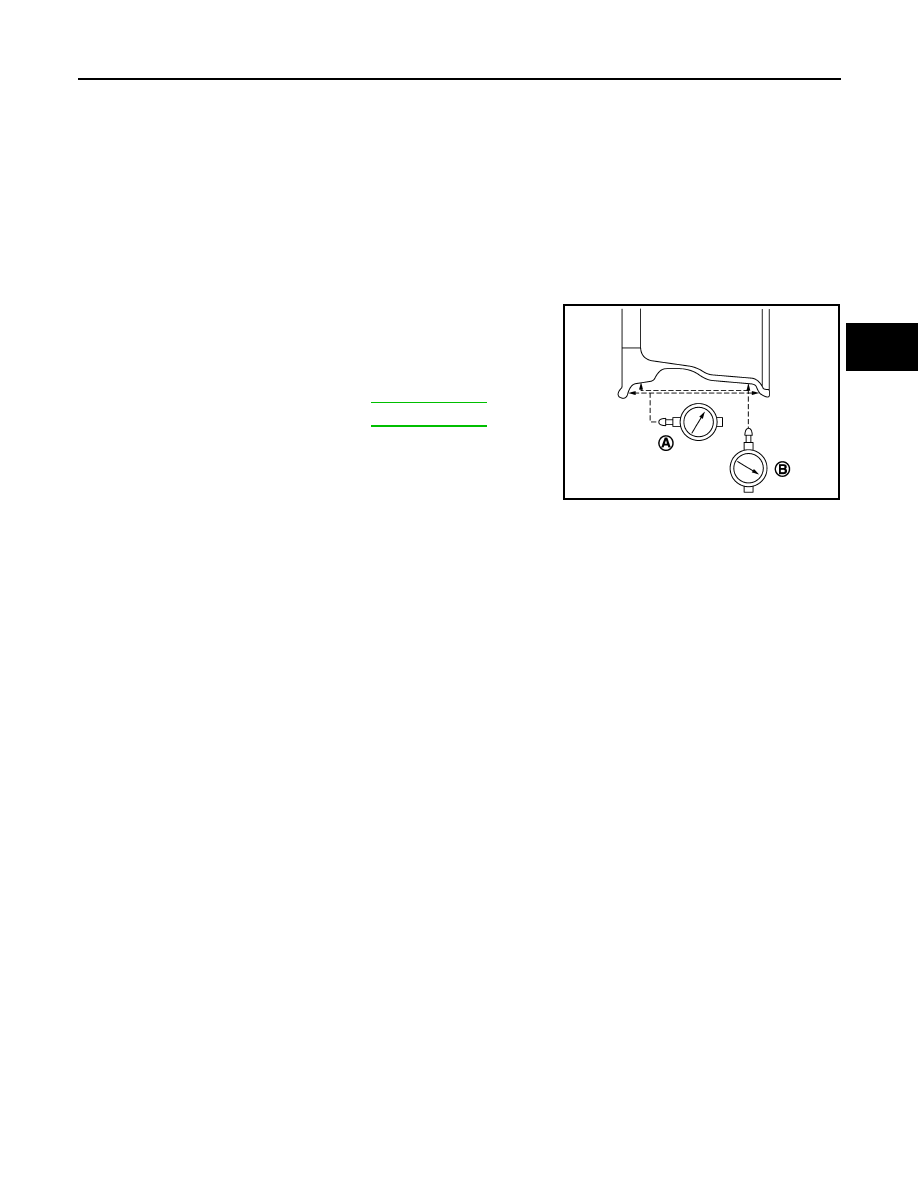

a. Remove tire from wheel and mount wheel on a balancer machine.

b. Set dial indicator as shown.

c. Check runout, if runout value exceeds the limit, replace wheel.

Limit

Axial Runout (A)

.

Radial Runout (B)

.

SEIA0737E