Nissan Versa Note. Manual - part 452

FUEL LEVEL SENSOR UNIT, FUEL FILTER AND FUEL PUMP ASSEMBLY

FL-7

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

K

L

M

A

FL

N

P

O

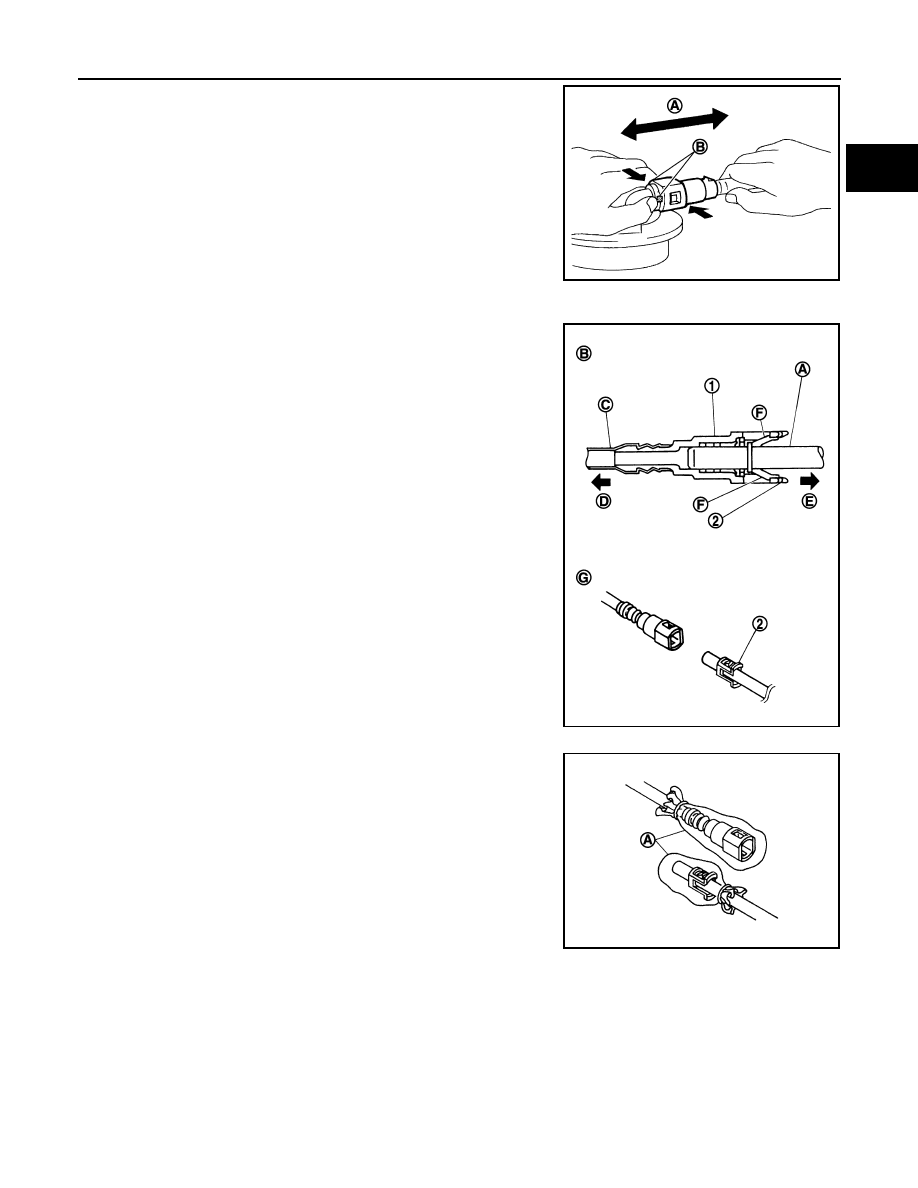

Remove the quick connector as follows:

• Hold the sides of the connector, push in tabs (B) and pull (A)

out the tube.

• If the connector and the tube are stuck together, push and pull

several times until they start to move. Then disconnect them

by pulling.

CAUTION:

• Quick connector (1) can be disconnected when the tabs

(F) are depressed completely. Do not twist it more than

necessary.

• Do not use any tools to disconnected quick connector.

• Keep resin tube (C) away from heat. Be especially careful

when welding near the resin tube.

• Prevent acid liquid such as battery electrolyte, etc. from

getting on resin tube.

• Do not bend or twist resin tube during installation and dis-

connection.

• Do not remove the remaining retainer (2) on hard tube (or

the equivalent) (A) except when resin tube or retainer is

replaced.

• When resin tube or hard tube (or the equivalent) is

replaced, also replace retainer with new one.

• To keep the connecting portion clean and to avoid dam-

age and foreign materials, cover them completely with

plastic bags (A) or something similar.

JPBIA0134ZZ

(B)

: Connection (cross-section)

(D)

: To under floor fuel line

(E)

: To fuel tank

(G)

: Disconnection

JPBIA0130ZZ

JPBIA0135ZZ