Nissan Versa Note. Manual - part 427

EXL-92

< SYMPTOM DIAGNOSIS >

PARKING, LICENSE PLATE AND TAIL LAMPS ARE NOT TURNED ON

PARKING, LICENSE PLATE AND TAIL LAMPS ARE NOT TURNED ON

Description

INFOID:0000000009694080

The parking, license plate and tail lamps do not turn ON in any combination switch (lighting and turn signal

switch) position.

Diagnosis Procedure

INFOID:0000000009694081

1.

COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH) INSPECTION

Check the combination switch (lighting and turn signal switch). Refer to

.

Is the combination switch (lighting and turn signal switch) normal?

YES

>> GO TO 2.

NO

>> Repair or replace the malfunctioning part.

2.

CHECK TAIL LAMP RELAY REQUEST SIGNAL INPUT

CONSULT DATA MONITOR

1. Select TAIL & CLR REQ of IPDM E/R DATA MONITOR item.

2. While operating the combination switch (lighting and turn signal switch), check the monitor status.

Is the item status normal?

YES

>> GO TO 3.

NO

>> Replace BCM. Refer to

BCS-70, "Removal and Installation"

(without Intelligent Key).

3.

PARK LAMP CIRCUIT INSPECTION

Check the parking lamp circuit. Refer to

EXL-11, "PARKING, LICENSE PLATE AND TAIL LAMP SYSTEM :

.

Is the tail lamp circuit normal?

YES

>> Replace IPDM E/R. Refer to

PCS-31, "Removal and Installation"

(with Intelligent Key) or

(without Intelligent Key).

NO

>> Repair or replace the malfunctioning part.

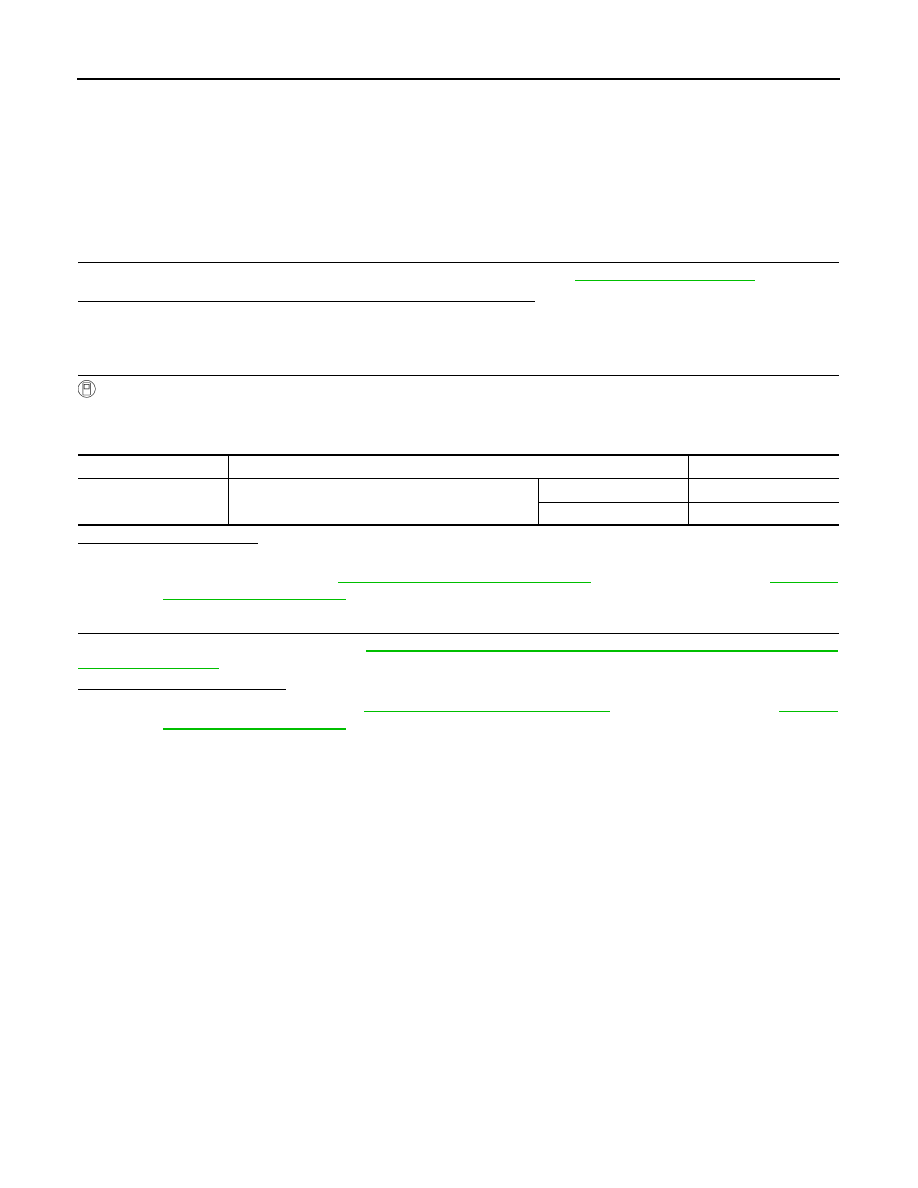

Monitor item

Condition

Monitor status

TAIL & CLR REQ

Combination switch (lighting and turn signal switch)

1st

ON

OFF

OFF