Nissan Versa Note. Manual - part 379

EM-32

< REMOVAL AND INSTALLATION >

[HR16DE]

EXHAUST MANIFOLD

7. Use Tool (A) to remove the air-fuel ratio sensor 1 with exhaust

manifold installed on vehicle (if necessary).

CAUTION:

• Handle air-fuel ratio sensor 1 carefully and avoid impacts.

• Before installing a new air-fuel ratio sensor 1, clean the

exhaust tube threads using suitable tool and approved

anti-seize lubricant.

• If air-fuel ratio sensor is dropped onto a hard surface,

such as a concrete floor, from a height of 0.5 m or more,

discard the sensor and use a new one.

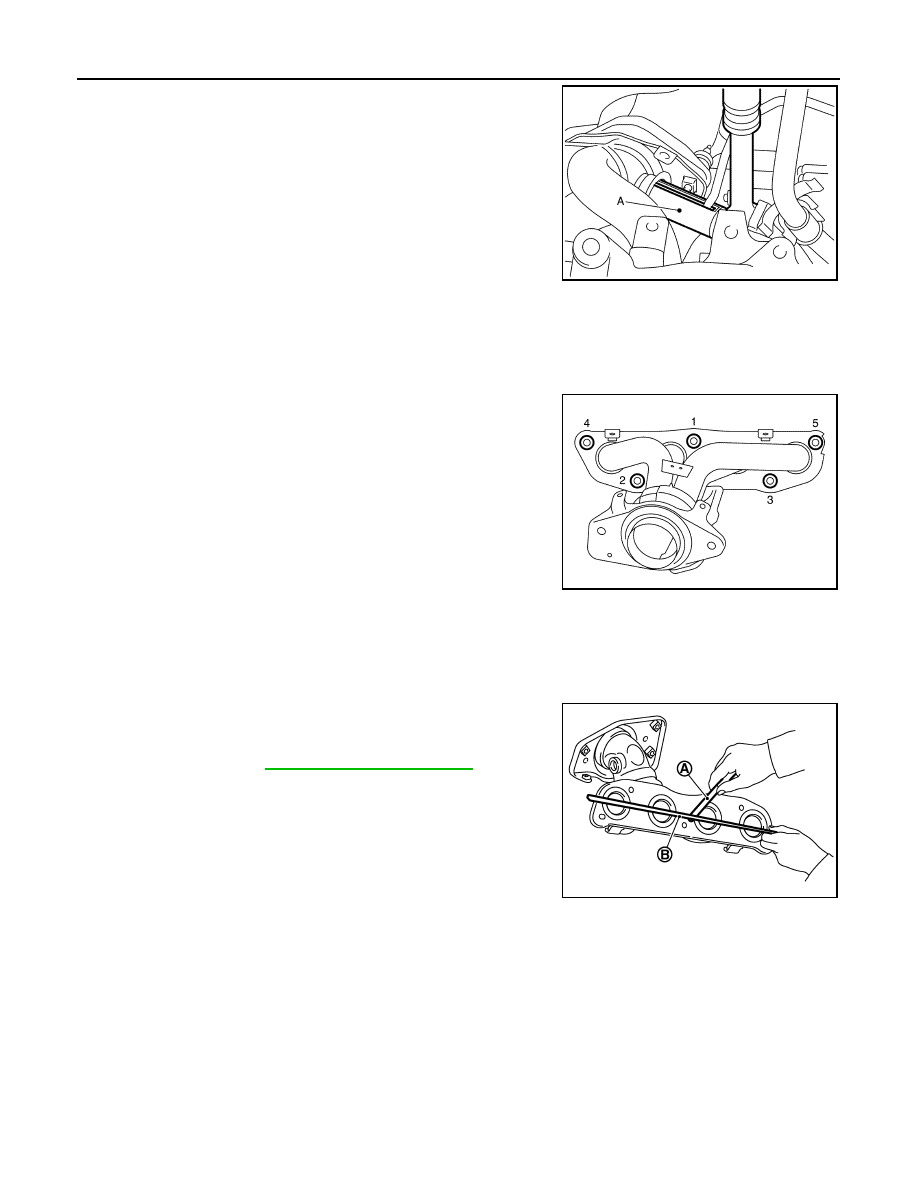

8. Remove exhaust manifold.

• Loosen nuts in reverse order as shown.

9. Remove exhaust manifold gasket.

10. Remove stud bolt using suitable tool from cylinder head (if necessary).

INSPECTION AFTER REMOVAL

Mounting Surface Distortion

• Using suitable tools (A) and (B), check the surface distortion of the

exhaust manifold mating surface as shown.

• Replace exhaust manifold if it exceeds the limit.

INSTALLATION

Installation is in the reverse order of removal. Note the following:

Exhaust manifold

1. Install new exhaust manifold gasket.

CAUTION:

Tool number

: KV10117100 ( — )

Oxygen sensor thread cleaner

: — (J-43897-12)

Oxygen sensor thread cleaner

: — (J-43897-18)

JPBIA4126ZZ

JPBIA4127ZZ

Limit

: Refer to

PBIC3530J