Nissan Versa Note. Manual - part 316

EC-246

< DTC/CIRCUIT DIAGNOSIS >

[HR16DE]

P0171 FUEL INJECTION SYSTEM FUNCTION

NO

>> GO TO 5.

5.

PERFORM DTC CONFIRMATION PROCEDURE-III

1. Turn ignition switch OFF and wait at least 10 seconds.

2. Start engine.

3. Maintain the following conditions for at least 10 consecutive minutes.

Hold the accelerator pedal as steady as possible.

CAUTION:

Always drive vehicle at a safe speed.

4. Check 1st trip DTC.

Is 1st trip DTC detected?

YES

>> Go to

NO

>> INSPECTION END

Diagnosis Procedure

INFOID:0000000009020750

1.

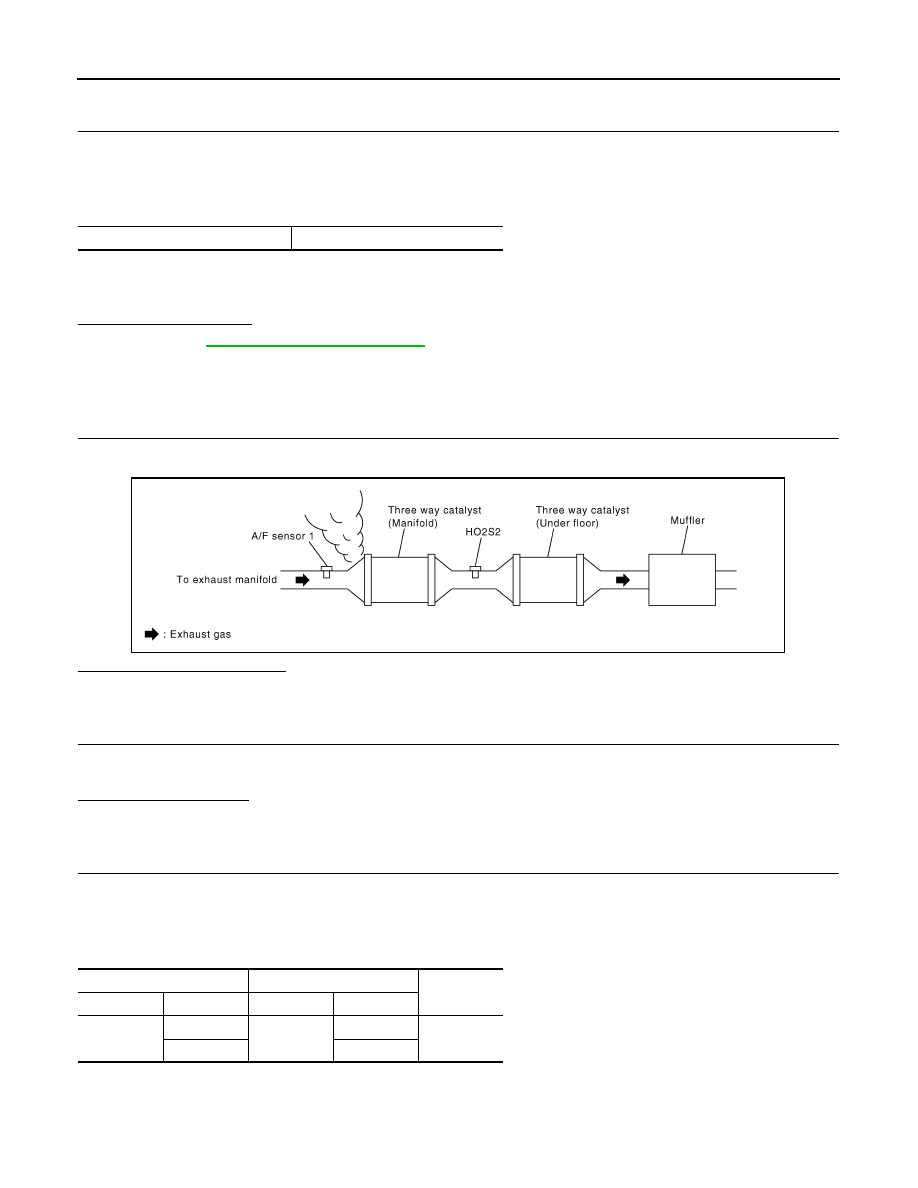

CHECK EXHAUST GAS LEAK

1. Start engine and run it at idle.

2. Listen for an exhaust gas leak before three way catalyst (manifold).

Is exhaust gas leak detected?

YES

>> Repair or replace.

NO

>> GO TO 2.

2.

CHECK FOR INTAKE AIR LEAK AND PCV HOSE

1. Listen for an intake air leak after the mass air flow sensor.

2. Check PCV hose connection.

Intake air leak detected?

YES

>> Repair or replace.

NO

>> GO TO 3.

3.

CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect corresponding A/F sensor 1 harness connector.

3. Disconnect ECM harness connector.

4. Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

5. Check the continuity between A/F sensor 1 harness connector or ECM harness connector and ground.

VHCL SPEED SE

50 – 120 km/h (31 – 75 MPH)

PBIB1216E

A/F sensor 1

ECM

Continuity

Connector

Terminal

Connector

Terminal

F12

1

F11

49

Existed

2

53