Nissan Rogue. Manual - part 738

HA-20

< SYMPTOM DIAGNOSIS >

COMPRESSOR SYSTEM SYMPTOMS

COMPRESSOR SYSTEM SYMPTOMS

Symptom Table

INFOID:0000000011279480

Follow the next table and perform trouble diagnosis if there is a compressor unit malfunction (internal noise,

insufficient cooling).

*1: First conduct inspection according to trouble diagnosis for each malfunction.

*2: Applicable to variable capacity compressor only.

Symptom

Inspection method

Check list

Result

Action

Noise from compressor unit

When A/C is ON.

(rattling or rolling sound)

Cooker system in-

ternal pressure

Check with manifold gauge

Both high- and low-

pressure sides are

high.

*2

Recharge with proper

amount of refrigerant.

High/low-pressures

hunt.

*2

Replace compressor

only.

Check compressor

oil condition.

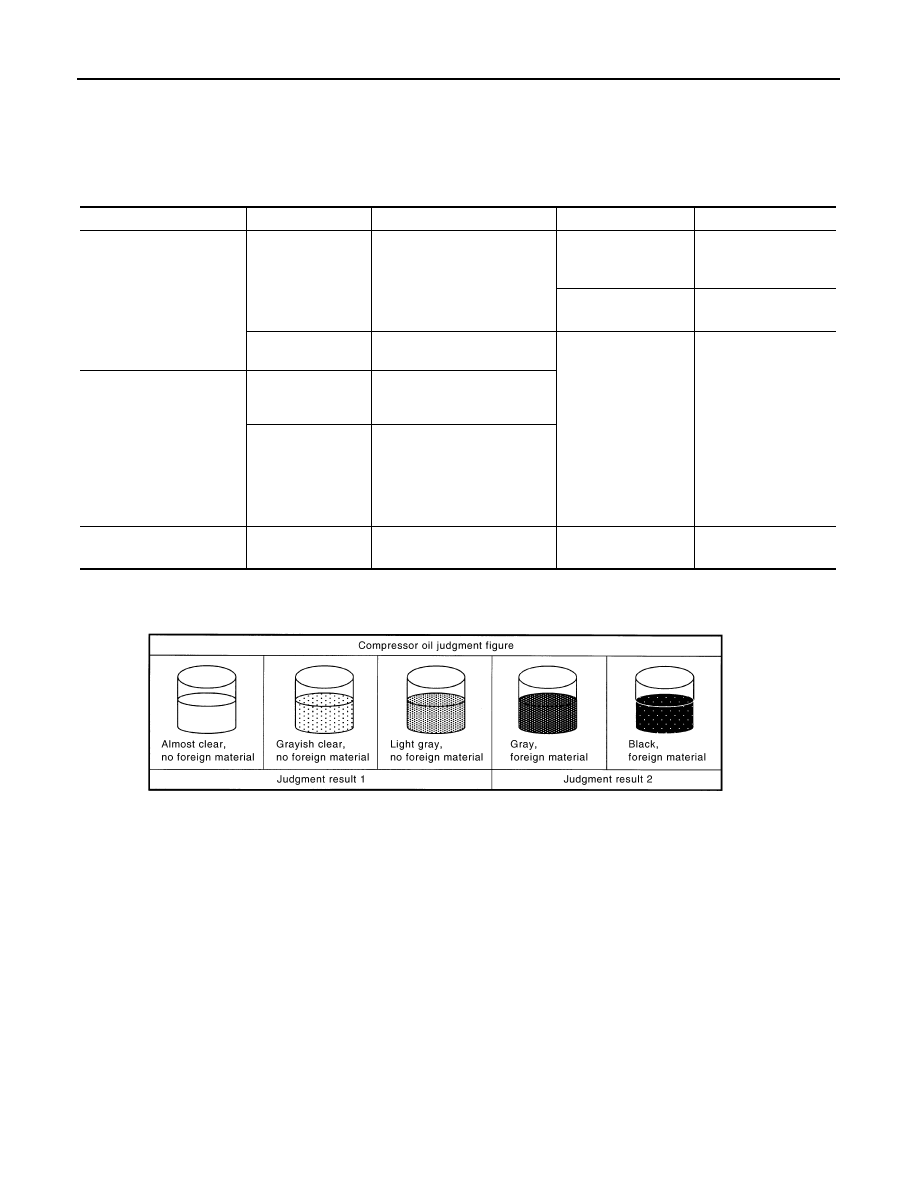

Sample compressor oil and

judge.

Refer to the criteria

shown in compressor

lubricant.

Judgment result 1: Re-

place compressor only.

Judgment result 2: Re-

place compressor and

liquid tank.

Insufficient cooling

*1

Compressor body

Check rotation of compressor.

If sized or stuck, sample com-

pressor oil and judge.

Cooler system inter-

nal pressure

Check with a manifold gauge.

Sample compressor oil and

judge if the difference between

high-pressure and low-pres-

sure is small or if they are al-

most the same.

Outlet air temperature rises

temporarily while driving.

*2

—

—

—

Replace compressor

only.

JSIIA0927GB