Nissan Rogue. Manual - part 733

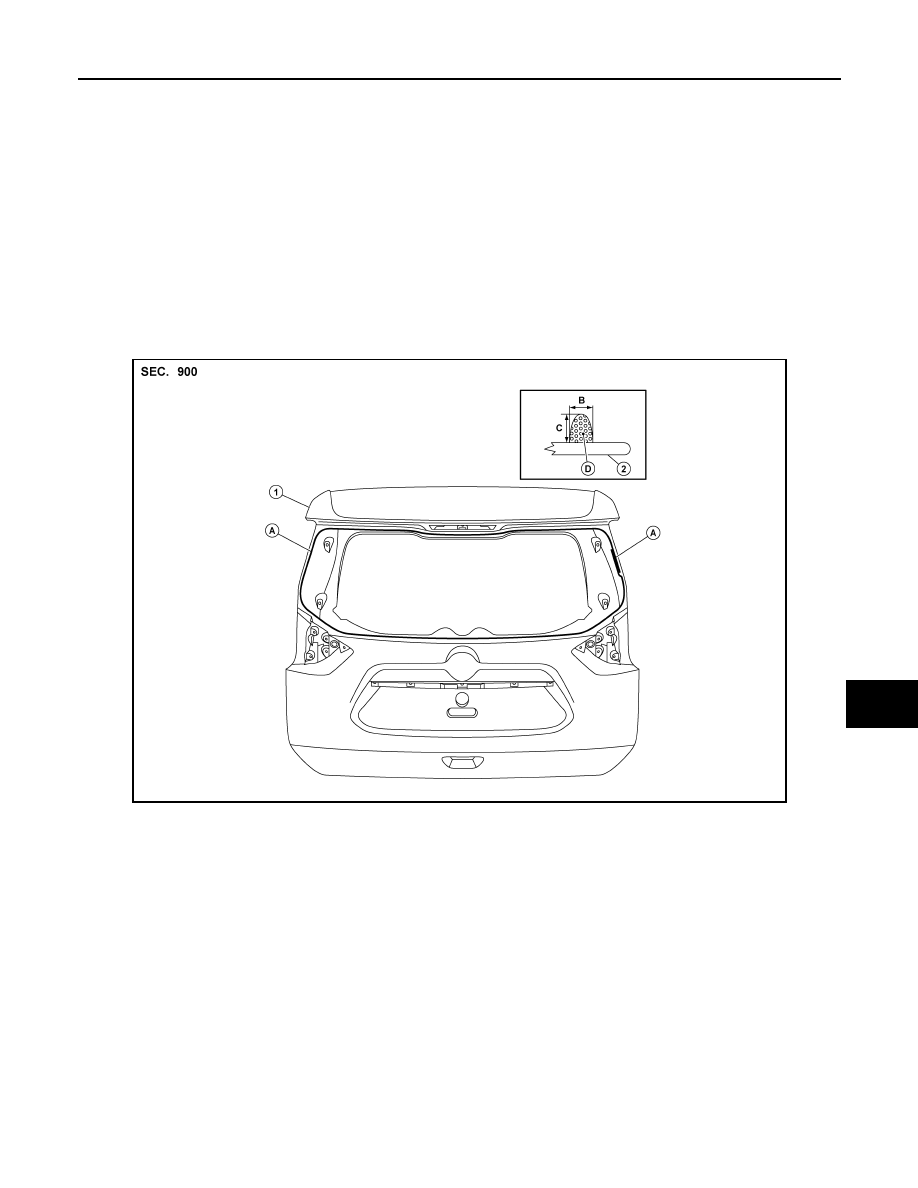

BACK DOOR WINDOW GLASS

GW-29

< REMOVAL AND INSTALLATION >

C

D

E

F

G

H

I

J

L

M

A

B

GW

N

O

P

• Keep heat and open flames away as primers and adhesive are flammable.

• Materials contained in the kit are harmful if swallowed, and may irritate skin and eyes. Avoid contact

with the skin and eyes.

• Use in an open, well ventilated location. Avoid breathing vapors. They can be harmful if inhaled. If

affected by vapor inhalation, immediately move to an area with fresh air.

• Driving vehicle before urethane adhesive has completely cured may affect performance of the wind-

shield in case of an accident.

CAUTION:

• Do not use adhesive which is past its usable term. Shelf life of this product is limited to six months

after date of manufacture. Carefully adhere to expiration or manufacture date printed on box.

• Keep primers and adhesive in cool, dry place. Ideally, they should be stored in refrigerator.

• Do not leave primers or adhesive cartridge unattended with their caps open or off.

• Vehicle should not be driven for at least 24 hours or until urethane adhesive has completely cured.

Curing time varies depending on temperature and humidity. Curing time will increase under lower

temperatures and lower humidity.

REPAIRING WATER LEAKS FOR BACK DOOR GLASS

• Leaks can be repaired without removing and reinstalling glass.

• Determine extent of leak, if water leaks between urethane adhesive material and body or glass.

• This can be done by applying water to glass area while pushing glass outward.

• Apply primer (if necessary) and then urethane adhesive to leak point to stop leak.

Inspection

INFOID:0000000011276526

REPAIRING WATER LEAKAGE FOR BACK DOOR WINDOW GLASS

Leakage can be repaired without removing the glass.

Determine the extent of leakage if water is leaking between the urethane adhesive material and body or glass.

This can be done by applying water to the back door window glass area while pushing glass outward.

Apply primer (if necessary) and then urethane adhesive to the leakage point to stop the leakage.

ALKIA3509ZZ

1. Back door

2. Back door window glass

A. Primer and adhesive area

B. 7.0 mm (0.28 in)

C. 12.0 mm (0.47 in)

D. Adhesive