Nissan Rogue. Manual - part 551

EC-472

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

FUEL PUMP

YES

>> GO TO 6.

NO

>> Repair or replace error-detected parts.

6.

CHECK FUEL PUMP

EC-472, "Component Inspection"

Is the inspection result normal?

YES

>> GO TO 7.

NO

>> Replace “fuel level sensor unit and fuel pump”. Refer to

FL-5, "Removal and Installation"

.

7.

CHECK INTERMITTENT INCIDENT

Perform

GI-44, "Intermittent Incident"

.

Is the inspection result normal?

YES

>> Replace IPDM E/R. Refer to

PCS-40, "Removal and Installation"

NO

>> Repair or replace harness or connectors.

Component Inspection

INFOID:0000000011278188

1.

CHECK FUEL PUMP

1. Turn ignition switch OFF.

2. Disconnect “fuel level sensor unit and fuel pump” harness connector.

3. Check resistance between “fuel level sensor unit and fuel pump” terminals as follows.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace “fuel level sensor unit and fuel pump”. Refer to

FL-5, "Removal and Installation"

.

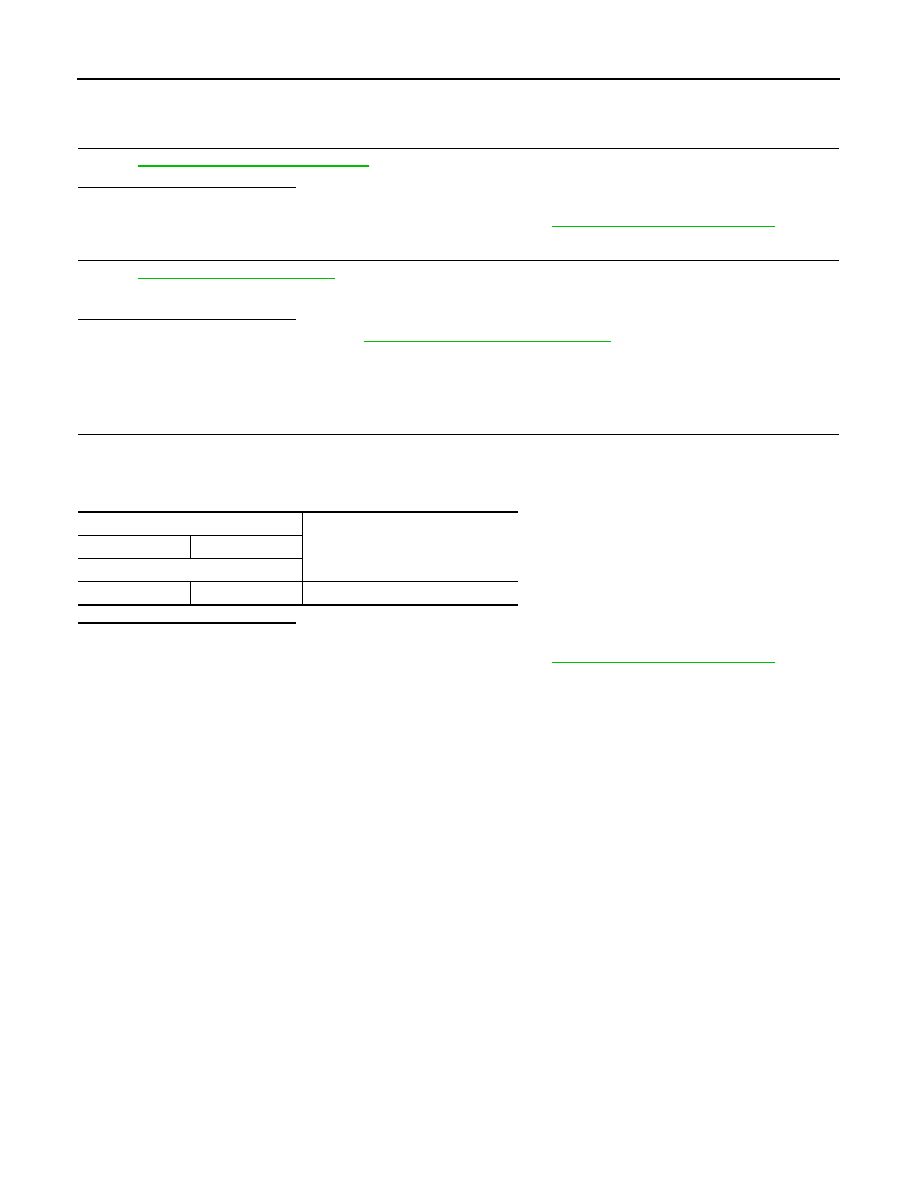

Fuel level sensor unit and fuel pump

Resistance

+

-

Terminal

6

4

0.2 - 5.0

Ω [at 25°C (77°F)]