Nissan Rogue. Manual - part 549

EC-464

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

COOLING FAN

Is the inspection result normal?

YES

>> GO TO 12.

NO

>> Replace malfunctioning cooling fan motor. Refer to

CO-17, "Removal and Installation"

.

12.

CHECK INTERMITTENT INCIDENT

Perform

GI-44, "Intermittent Incident"

.

Is the inspection result normal?

YES

>> Replace IPDM E/R. Refer to

PCS-40, "Removal and Installation"

NO

>> Repair or replace error-detected parts.

Component Inspection (Cooling Fan Motor)

INFOID:0000000011278177

1.

CHECK COOLING FAN MOTOR

1. Turn ignition switch OFF.

2. Disconnect cooling fan motor harness connector.

3. Supply cooling fan motor terminals with battery voltage and check operation.

Check that cooling fan speed of condition B is higher than that of A.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace cooling fan motor. Refer to

CO-17, "Removal and Installation"

Component Inspection (Cooling Fan Relay)

INFOID:0000000011278178

1.

CHECK COOLING FAN RELAYS

1. Turn ignition switch OFF.

2. Remove cooling fan relay-2, -3.

3. Check the continuity between cooling fan relay-2, -3 terminals as per the following conditions.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace cooling fan relay.

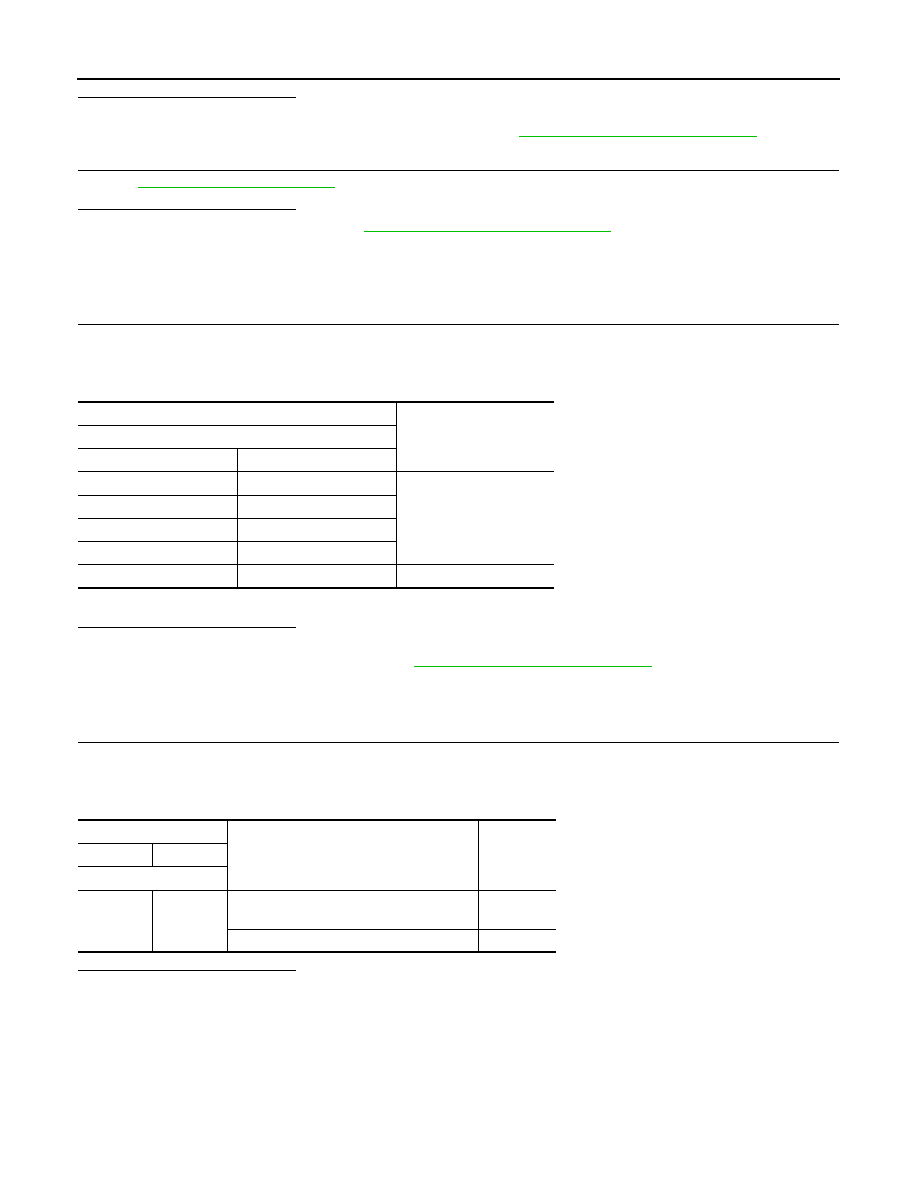

Cooling fan motor

Condition

Terminal

+

–

1

3 and 4

A

2

3 and 4

1 and 2

3

1 and 2

4

1, 2

3, 4

B

Cooling fan relay-2, -3

Conditions

Continuity

+

−

Terminal

3

5

12V direct current supply between termi-

nals 1 and 2

Existed

No current supply

Not existed