Nissan Rogue. Manual - part 483

EC-200

< DTC/CIRCUIT DIAGNOSIS >

[QR25DE]

P0078 EVT CONTROL SOLENOID VALVE

YES

>> GO TO 2.

NO

>> Replace exhaust valve timing control solenoid valve. Refer to

.

2.

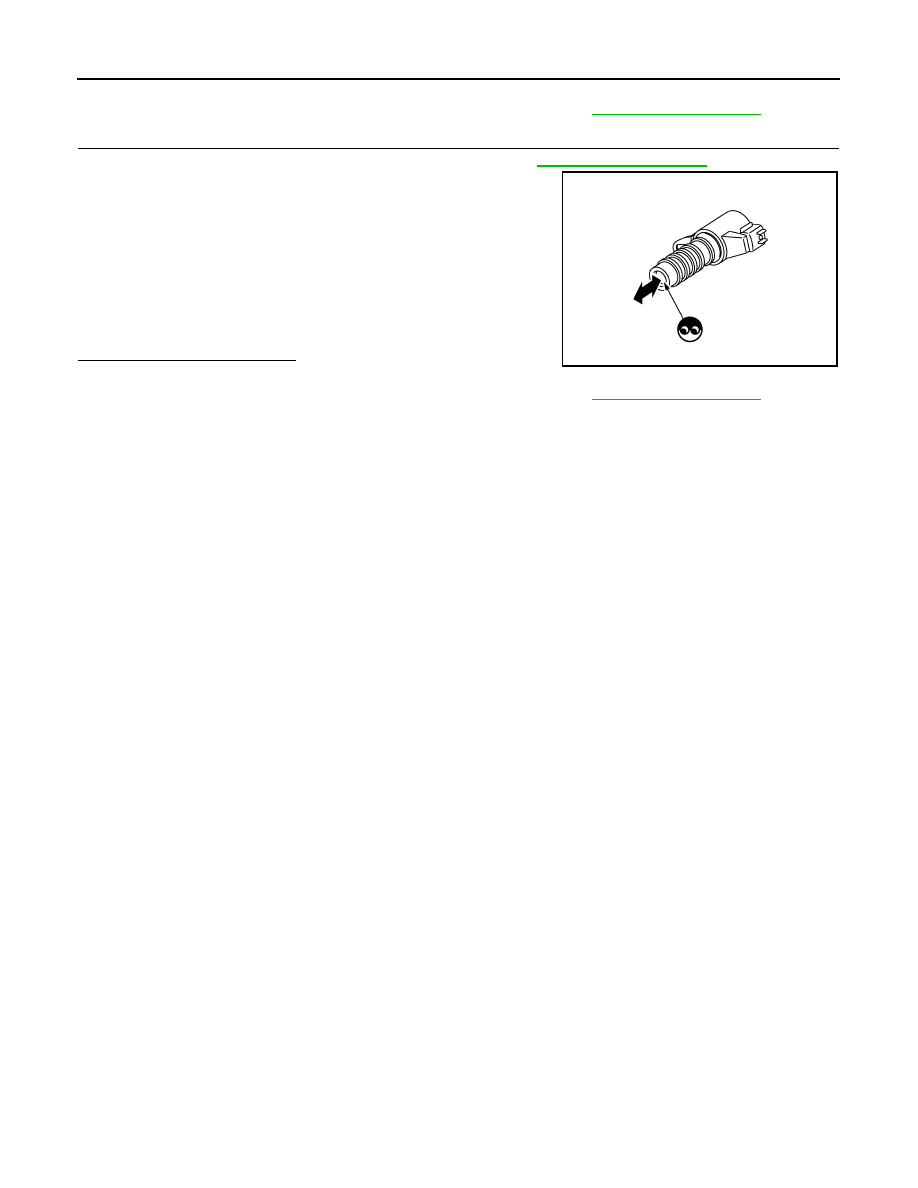

CHECK EXHAUST VALVE TIMING CONTROL SOLENOID VALVE-2

1. Remove exhaust valve timing control solenoid valve. Refer to

.

2. Provide 12 V DC between exhaust valve timing control solenoid

valve terminals 1 and 2, and then interrupt it. Check that the

plunger moves as shown in the figure.

CAUTION:

Do not apply 12 V DC continuously for 5 seconds or more.

Doing so may result in damage to the coil in exhaust valve

timing control solenoid valve.

NOTE:

Always replace O-ring when exhaust valve timing control

solenoid valve is removed.

Is the inspection result normal?

YES

>> INSPECTION END

NO

>> Replace exhaust valve timing control solenoid valve. Refer to

.

JMBIA0079ZZ