Nissan Rogue. Manual - part 467

EC-136

< BASIC INSPECTION >

[QR25DE]

BASIC INSPECTION

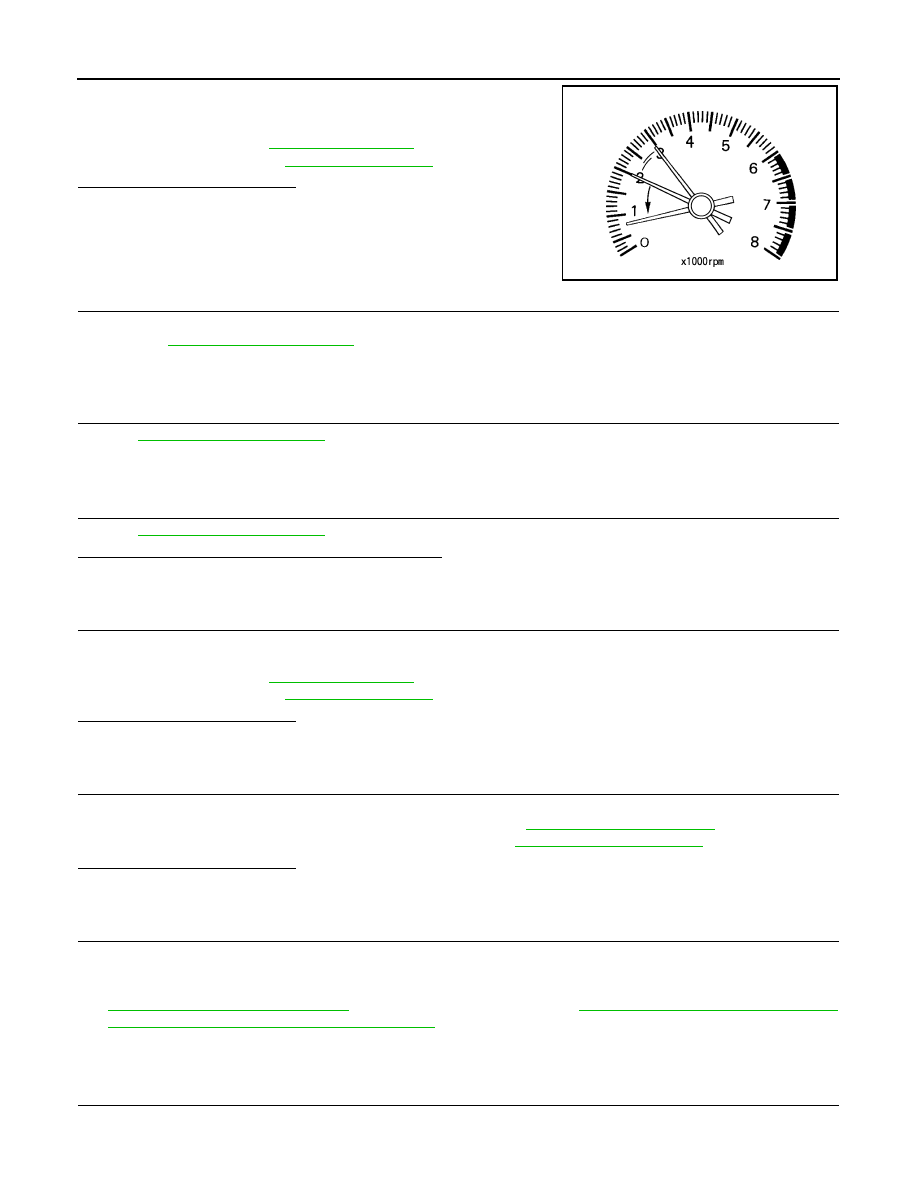

2. Rev engine (2,000 to 3,000 rpm) two or three times under no

load, then run engine at idle speed for about 1 minute.

3. Check idle speed.

For procedure, refer to

.

For specification, refer to

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> GO TO 4.

4.

PERFORM ACCELERATOR PEDAL RELEASED POSITION LEARNING

1. Stop engine.

2. Perform

.

>> GO TO 5.

5.

PERFORM THROTTLE VALVE CLOSED POSITION LEARNING

Perform

>> GO TO 6.

6.

PERFORM IDLE AIR VOLUME LEARNING

Perform

Is Idle Air Volume Learning carried out successfully?

YES

>> GO TO 7.

NO

>> Follow the instruction of Idle Air Volume Learning. Then GO TO 4.

7.

CHECK TARGET IDLE SPEED AGAIN

1. Start engine and warm it up to normal operating temperature.

2. Check idle speed.

For procedure, refer to

.

For specification, refer to

Is the inspection result normal?

YES

>> GO TO 10.

NO

>> GO TO 8.

8.

DETECT MALFUNCTIONING PART

Check the Following.

• Check camshaft position sensor (PHASE) and circuit. Refer to

• Check crankshaft position sensor (POS) and circuit. Refer to

.

Is the inspection result normal?

YES

>> GO TO 9.

NO

>> Repair or replace. Then GO TO 4

9.

CHECK ECM FUNCTION

1. Substitute another known-good ECM to check ECM function. (ECM may be the cause of an incident, but

this is a rare case.)

2. Perform initialization of NVIS (NATS) system and registration of all NVIS (NATS) ignition key IDs. Refer to

SEC-66, "ECM : Work Procedure"

(With intelligent key system) or

ING FUNCTION : Special Repair Requirement"

(Without intelligent key system).

>> GO TO 4.

10.

CHECK IGNITION TIMING

1. Run engine at idle.

PBIA8513J