Nissan Rogue. Manual - part 424

DLN-140

< UNIT DISASSEMBLY AND ASSEMBLY >

[REAR FINAL DRIVE: R145]

DRIVE PINION

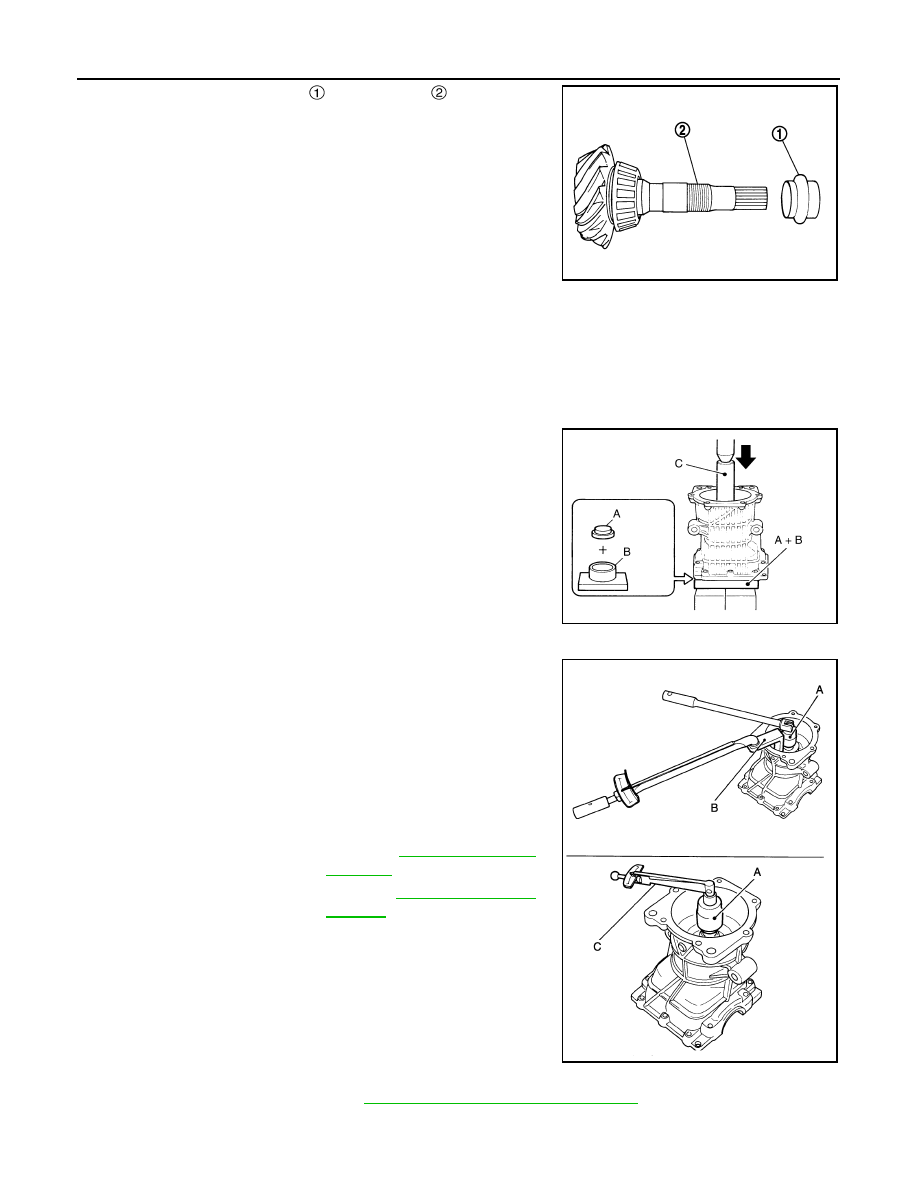

5. Assemble collapsible spacer to drive pinion .

CAUTION:

• Be careful of the mounting direction of collapsible spacer.

• Never reuse collapsible spacer.

6. Assemble drive pinion into gear carrier.

CAUTION:

Apply gear oil to pinion rear bearing.

7. Assemble pinion front bearing inner race to drive pinion assembly.

CAUTION:

• Never reuse pinion front bearing inner race.

• Apply gear oil to pinion front bearing.

8. Using the drifts (A and C) and press stand (B), press pinion front

bearing inner race to drive pinion as far as drive pinion lock nut

can be tightened.

9. Apply anti-corrosion oil to the thread and seat of drive pinion

lock nut, and temporarily tighten drive pinion lock nut to drive

pinion.

CAUTION:

Never reuse drive pinion lock nut.

10. Fit the drive pinion socket (A) onto the drive pinion. While hold-

ing drive pinion, tighten drive pinion lock nut within the limits of

specified torque so as to keep the pinion bearing preload within

a standard values, using the pinion nut wrench (B) and the pre-

load gauge (C).

CAUTION:

• Adjust the lower limit of the drive pinion lock nut tighten-

ing torque first.

• If the preload torque exceeds the specified value, replace

collapsible spacer and tighten it again to adjust. Never

loose n drive pinion lock nut to adjust the preload torque.

• After adjustment, rotate drive pinion back and forth 2 to 3

times to check for unusual noise, rotation malfunction,

and other malfunctions.

11. Install differential assembly. Refer to

DLN-126, "Disassembly and Assembly"

.

CAUTION:

Never install rear cover at this timing.

JSDIA0317ZZ

A

: Drift [SST: KV40100610 (J-26089)]

B

: Press stand [SST: ST38220000 ( — )]

C

: Drift [SST: ST23860000 ( — )]

A

: Drive pinion socket [SST: KV38109500 ( — )]

B

: Pinion nut wrench [SST: KV38109400 ( — )]

C

: Preload gauge [SST: ST3127S000 (J-25765-A)]

Drive pinion lock nut

tightening torque

: Refer to

.

Pinion bearing preload

JSDIA5302ZZ

JSDIA0266ZZ