Nissan Rogue. Manual - part 415

DLN-104

< SERVICE DATA AND SPECIFICATIONS (SDS)

[REAR PROPELLER SHAFT: C-CVJ-C]

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

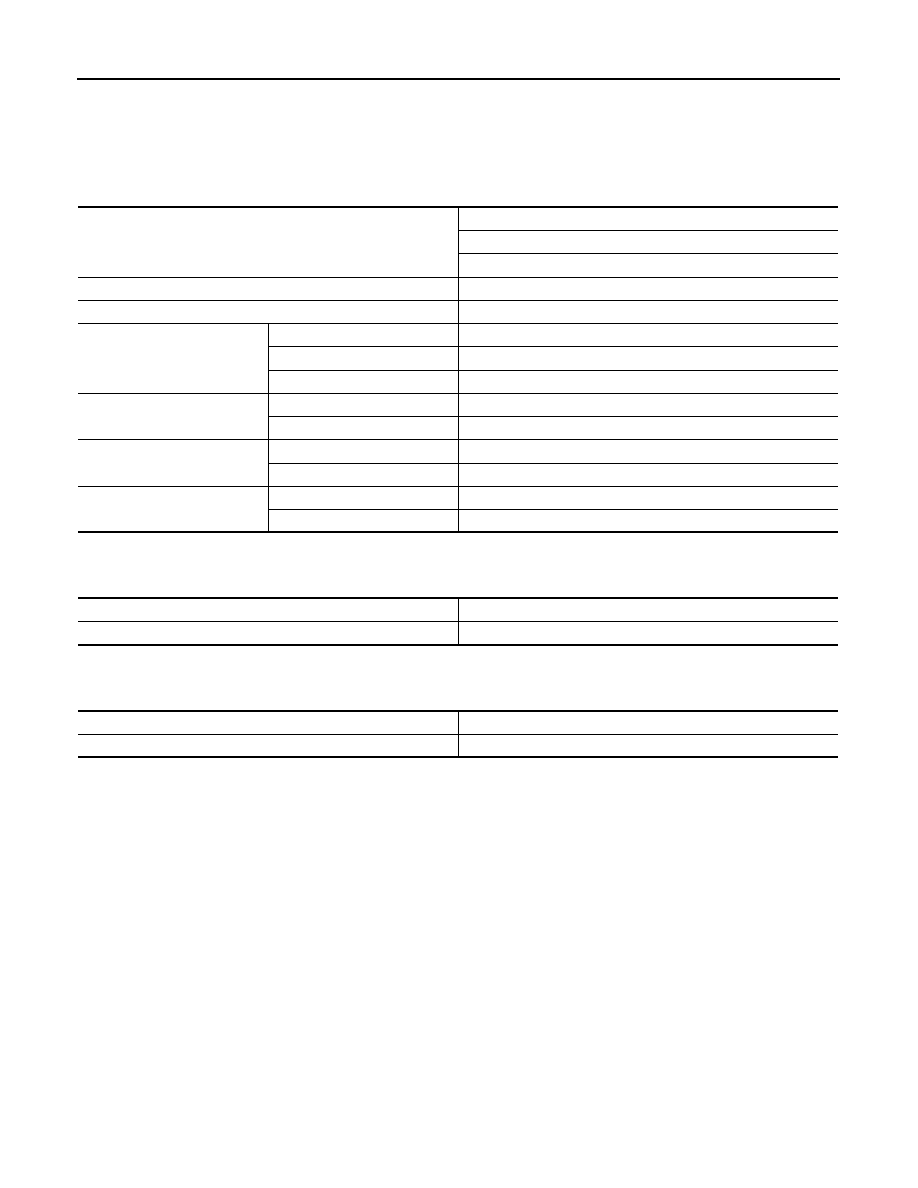

General Specifications

INFOID:0000000011278395

Propeller Shaft Runout

INFOID:0000000011278396

Unit: mm (in)

Journal Axial Play

INFOID:0000000011278397

Unit: mm (in)

Applied model

AWD

QR25DE

CVT

Propeller shaft model

C-CVJ-C

Number of joints

3

Joint type

1st joint

Universal (Shell type)

2nd joint

CVJ type

3rd joint

Universal (Shell type)

Coupling method

Transfer side

Flange type

Rear final drive side

Flange type

Shaft length

1st (Spider to CVJ joint center)

1196 mm (47.09 in)

2nd (CVJ joint center to spider)

983 mm (38.70 in)

Shaft outer diameter

1st

63.5 mm (2.500 in)

2nd

70.0 mm (2.756 in)

Item

Standard

Propeller shaft runout

0.6 (0.024) or less

Item

Standard

Journal axial play

0 (0)